8

Vari-Green

®

Motor Option

Model G

Greenheck’s electronically commutated (EC)

Vari-Green (VG) motor combines motor

technology, controllability and energy-efficiency

into one single low maintenance unit and is the

industry’s first fully controllable motor. When combined

with Greenheck’s G fans, all the CFM and static

pressure ranges of a belt drive can be attained with the

benefits of a direct drive.

Benefits

Operates on AC power that’s converted to DC—

providing a more efficient motor operation as compared

to an AC operation.

• The motor can attain up to 85% efficiency and

reduce energy consumption.

• Watt savings of 30-70% depending on RPM.

Note: As motor speed is turned down, efficiency stays high

as compared to an AC motor that decreases dramatically.

• Operates cooler than a standard AC motor at lower

RPMs. A cooler motor has longer motor life and

reduces energy consumption.

• 80% usable RPM turndown versus 30%, see Motor

Turndown Comparison chart at right.

• G fans with Vari-Green motors can provide all the

CFM and static pressure ranges of a comparable

belt drive.

• Maintenance costs are reduced as there are

no belts or bearings to replace and no pulleys

to adjust.

• Direct drive fans are often preferred where

maintenance access is difficult.

• Provides a solution for demand controlled ventilation

applications.

Vari-Green Advantages

• Initial cost is similar to a belt drive

• Lower operating cost

• No maintenance, no belts, pulleys or bearings

• Easy RPM adjustment

8

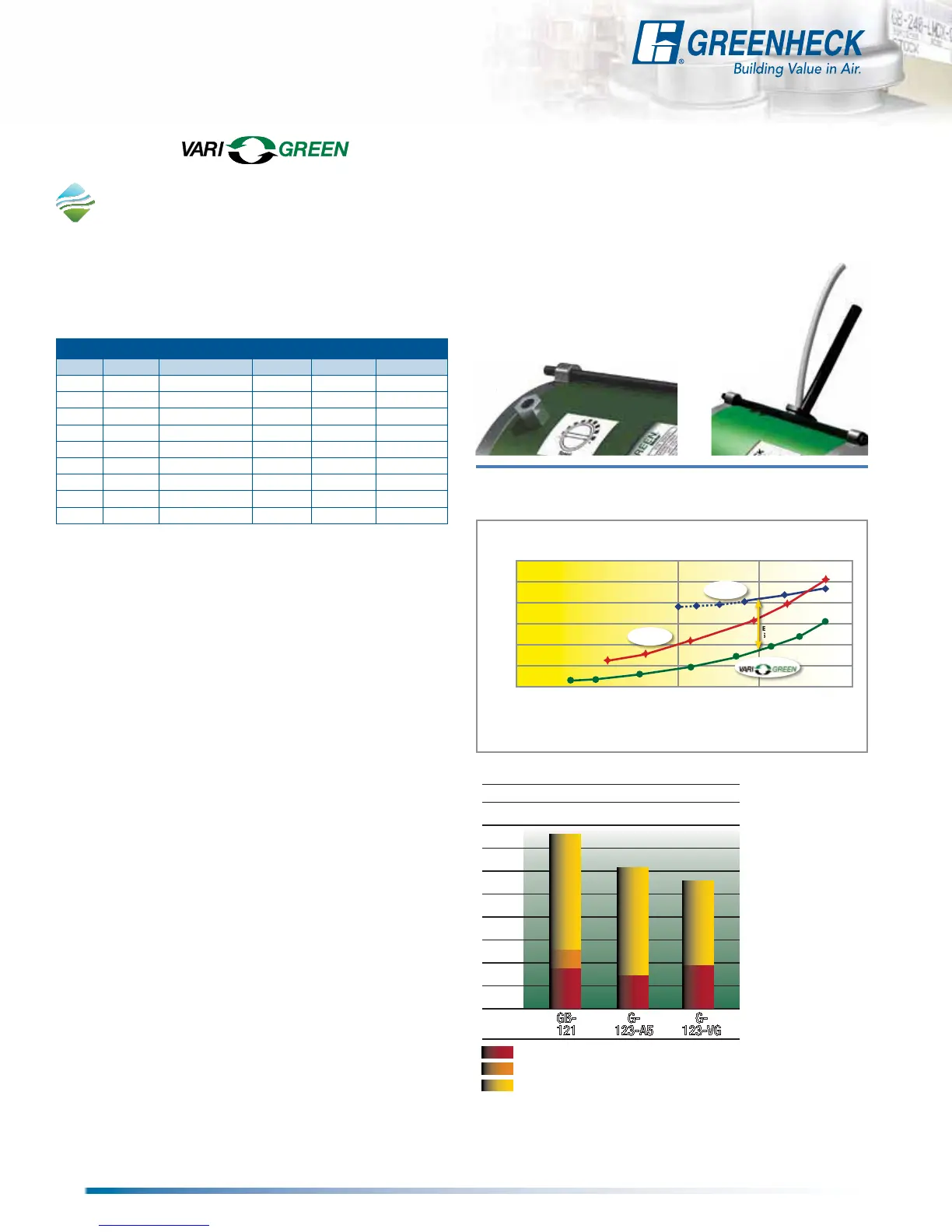

600

500

400

300

200

100

0

0 350

50% 75% 100%

1750

FAN SPEED (RPM)

INPUT POWER (WATTS)

Energy

Savings

G-123

with PSC

Not recommended

GB-123

Single Phase*

G-123 with

*

GB is a belt driven fan

The length of each curve indicates the practical turndown range.

Data is for 1/2 hp motors with load of 0.35 Bhp at full speed

Motor Turndown Comparison

Features

1. Dial on Motor Control - a potentiometer (dial on

motor control) is mounted on the motor for easy

speed adjustment for system balance. Simply turn

the dial. There are no belts and pulleys to adjust.

2. Control Wire Inputs - the motor accepts a

0-10V DC signal from Building Automated

Systems or other controls to adjust

motor speed.

1

2

1

®

Comparisons: Belt, Direct Drive with PSC

and Direct Drive with Vari-Green

Analysis is based on operating costs for a period of three years where

the fans operate continuously at 1725 rpm, 24/7, with an energy rate

of $0.10/kWh. Maintenance on the GB-121 is estimated at $65/yr.

Note: Example is based on a relative cost. Use and installation

variables may produce different results.

$

2,000

1,750

1,500

1,250

1,000

750

500

250

$

0

CUBE-

121

Three Year Cost Comparison

Initial Cost

Maintenance cost over three years

Operating cost over three years

CUE-

121-A5

CUE-

121-VG

Constant Volume Life Cycle Analysis

GB-

121

G-

123-A5

G-

123-VG

Motor Information

HP RPM Volts Phase FLA Enclosure

1/6 1725 115 Single 3.1 TENV

1/4 1725 115 Single 3.9 ODP

1/2 1725 115 Single 6.2 ODP

1/2 2500 115 Single 6.5 ODP

3/4 1725 115 Single 10.1 ODP

3/4 2200 115 Single 11.3 ODP

1 1725 115 Single 12.4 ODP

1 1725 115/208-230 Single

12.0/6.0

TEFC

2 1725 208-230 Single 12.0 TEFC

Loading...

Loading...