5

Fire Ready Hood

Preparing the Install Location

Mounting Bracket - The mounting bracket and hood must be centered over the range. If the range is not in place,

the center marking should be relative to it’s final position. Refer to page 7 for bracket mounting points, rear access

holes and access points.

Ductwork - The ductwork and fittings used for outside venting (if applicable) must be carefully selected to ensure

that the static pressure is in line with the fan parameters. The table below displays maximum duct length allowed for

the various fan options.

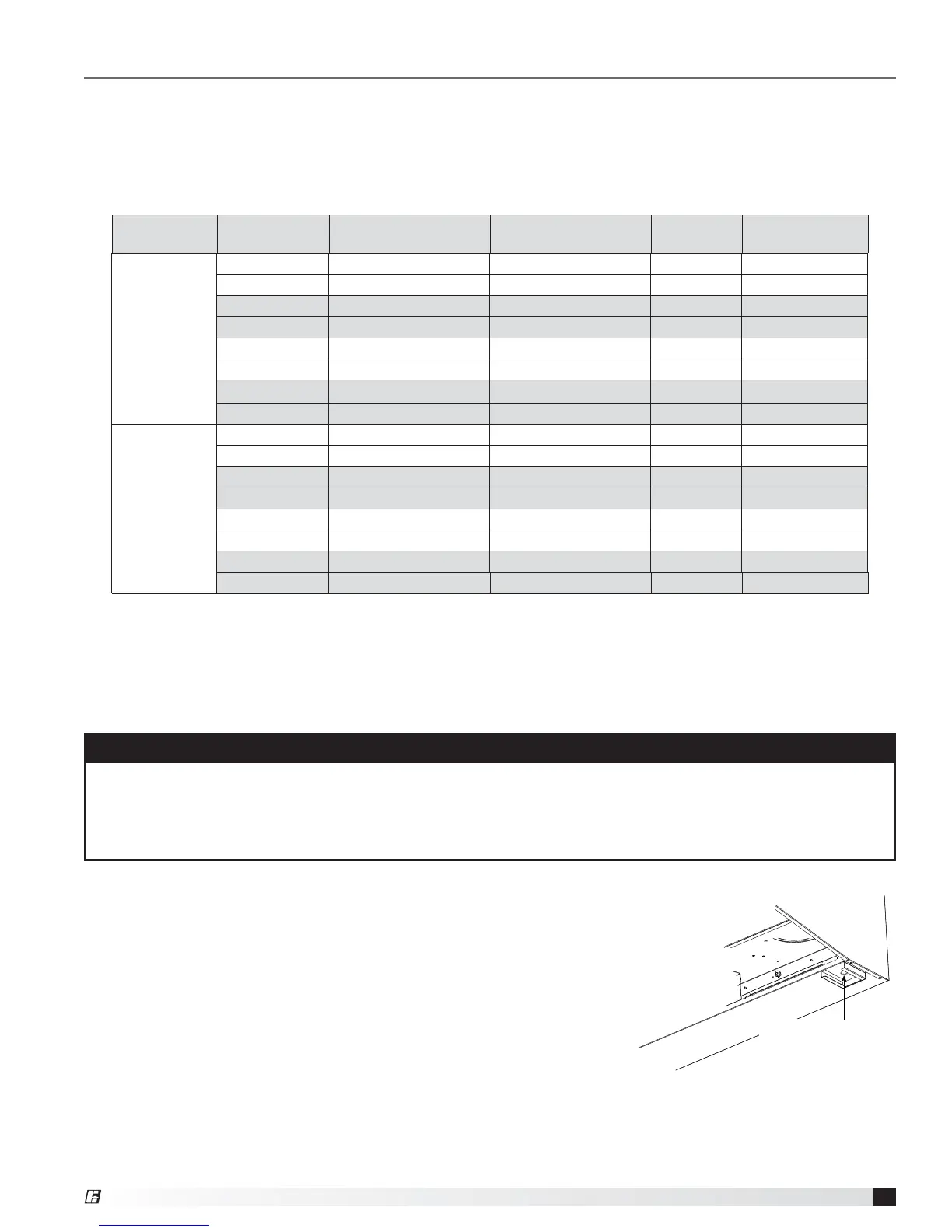

Hood

Width

NFPA 101

Compliance

Fan Type Venting

CFM

(at hood)

Duct Length

(maximum)

30 inches

No Internal Front (recirculating) 140 Not applicable

No Internal Rear (recirculating) 250 Not applicable

No Inline Duct Fan Vertical Duct 470 35 feet

No Exterior Wall Fan Vertical Duct 150 20 feet

Yes Internal Front (recirculating) 500 Not applicable

Yes Internal Rear (recirculating) 500 Not applicable

Yes Inline Duct Fan Vertical Duct 510 35 feet

Yes Exterior Wall Fan Vertical Duct 550 20 feet

36 inches

No Internal Front (recirculating) 140 Not applicable

No Internal Rear (recirculating) 250 Not applicable

No Inline Duct Fan Vertical Duct 470 35 feet

No Exterior Wall Fan Vertical Duct 150 20 feet

Yes Internal Front (recirculating) 150 Not applicable

Yes Internal Rear (recirculating) 500 Not applicable

Yes Inline Duct Fan Vertical Duct 510 35 feet

Yes Exterior Wall Fan Vertical Duct 550 20 feet

Maximum duct length equals horizontal and vertical duct runs plus duct components such as fittings, elbows, and transitions.

For installations requiring vertical duct venting to an inline fan and NFPA 101 compliance, the hood should be

adapted from a 7-inch round duct access hole to a minimum 12-inch duct.

For installations requiring vertical duct venting to an inline fan and NFPA 101 compliance is NOT required, the hood

can be adapted to a minimum 10-inch duct.

WARNING

The amount of fittings and ductwork directly affects the resistance or static pressure placed on the system. If the

system is not within the proper static pressure range, the heat sensors and controls will be adversely affected and

will impact the proper function of the safety controls. Therefore it is required that airflow testing be recorded along

with installation documentation. The air testing is accessed by the removal of the grease tray and measured with

an airflow pressure gauge.

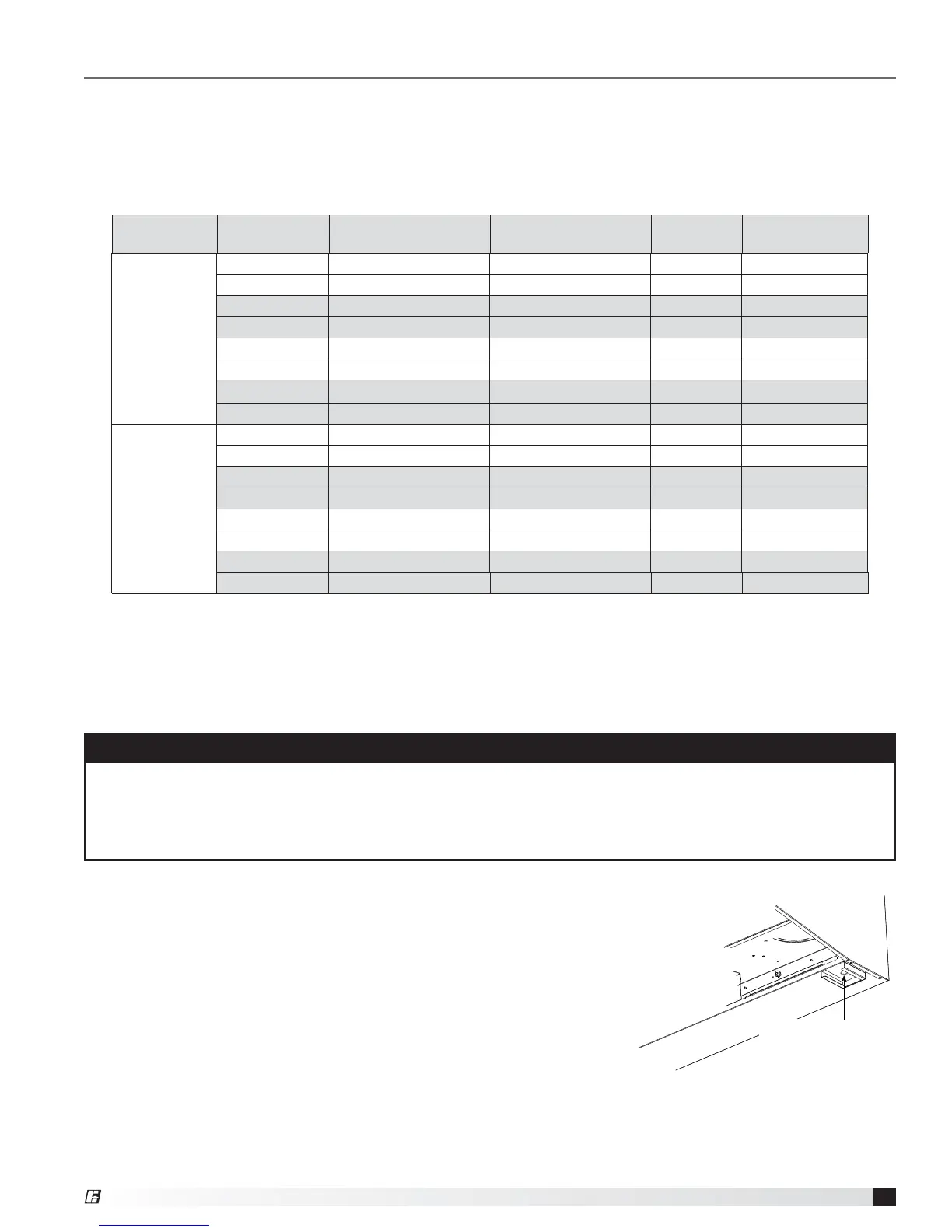

Static Pressure Testing - The magnehelic gauge test port opening is located

beneath the grease tray. The static pressure needs to be measured to ensure

airflows meet design criteria. The airflow is measured by attaching the gauge

tubing to the magnehelic gauge inlet, and the hood fitting is attached to the

grease drain hole beneath the grease tray.

A reading of 0.45 to 0.85 inches wg. is required to meet design standards.

This reading will correspond to the static pressure of the ductwork, hood

and fan combination.

Magnehelic Gauge

Test Port

Magnehelic Gauge

Test Port

®

Loading...

Loading...