Indirect Gas-Fired Heat Modules8

Venting Methods

There are three venting methods for indoor mounted

units. For each method, the units can be vented

horizontally through an exterior wall or vertically

through the roof. Specific venting instructions are

provided for each method and shown in the following

pages. Construct the vent system as shown in these

instructions. Refer to your unit specific submittal to

determine the applicable venting option.

The venting method options are:

Standard Indoor Venting

• uses building air for combustion

• vents exhaust to outdoors

• one exterior roof or wall penetration

Separated Combustion Concentric Venting

• uses outside air for combustion

• vents exhaust to outdoors

• one exterior roof or wall penetration

Separated Combustion 2-Pipe Venting

• uses outside air for combustion

• vents exhaust to outdoors

• two exterior roof or wall penetrations

NOTE

For each method, the units can be vented horizontally

through an exterior wall or vertically through the roof.

Refer to the specific venting instructions for your

unit. Construct the vent system as shown in these

instructions.

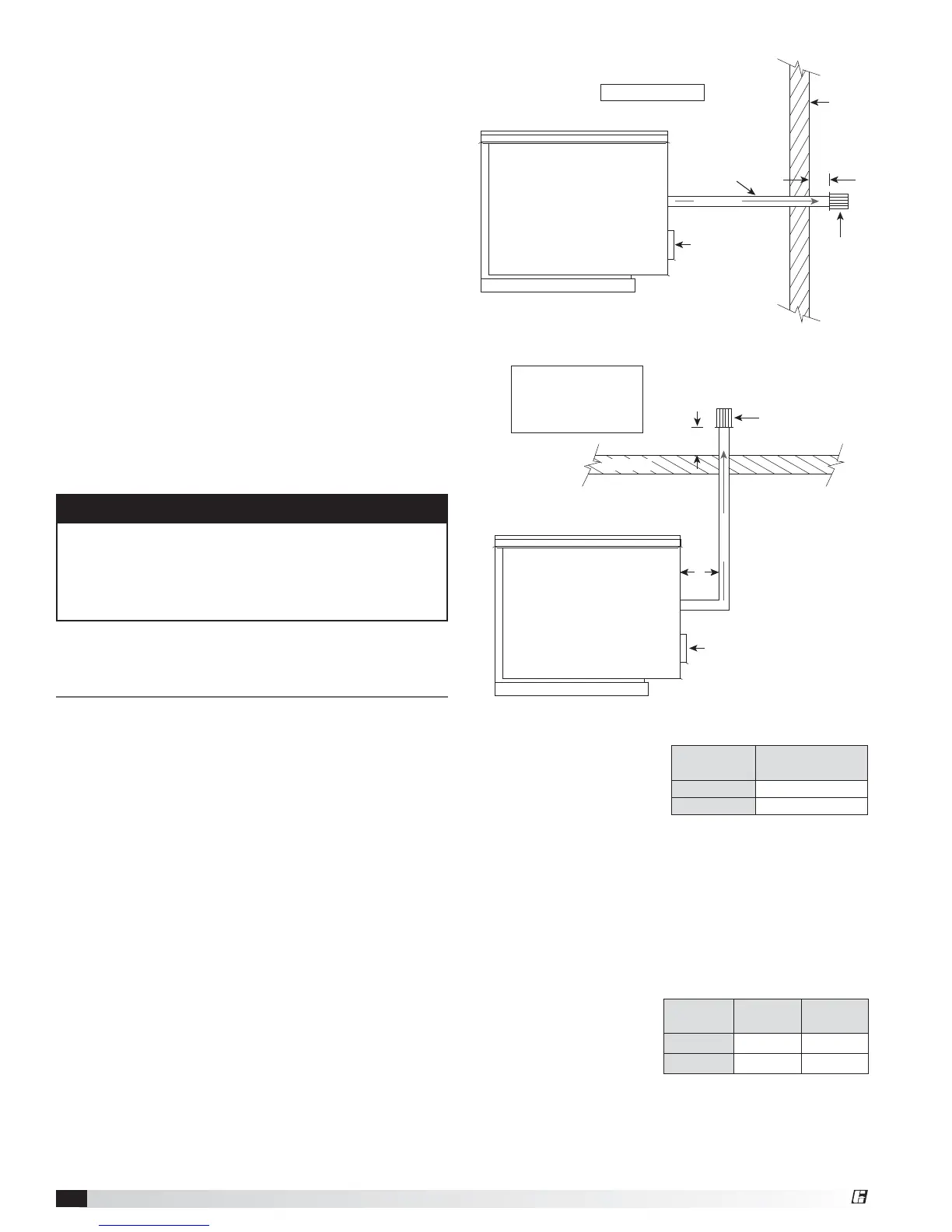

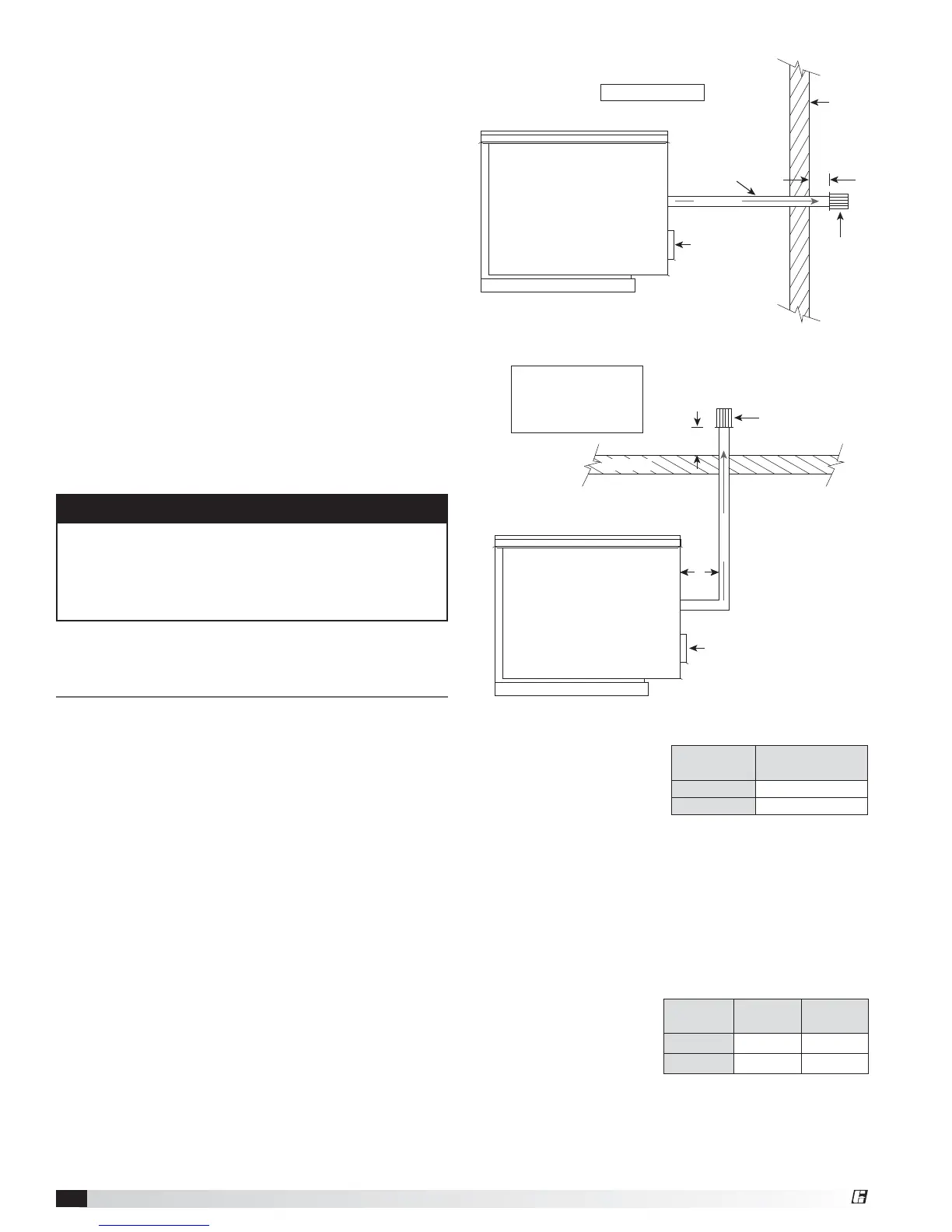

Installation of Standard Indoor

Venting

Standard indoor venting uses one penetration through

an exterior wall or roof for venting the flue exhaust.

The combustion air is supplied from the air inside the

building. Units must not be installed in a potentially

explosive, flammable, or corrosive atmosphere. To

prevent premature heat exchanger failure, do not locate

unit where chlorinated, halogenated or acid vapors are

present.

When units are installed in tightly sealed buildings,

provisions should be made to supply an adequate

amount of infiltration air from the outside. The rule of

thumb is that an opening of one square inch should be

provided for every 1000 BTUs per hour of input rating.

Vent terminals must be used. Construct the vent

system as shown in the drawings. Reference the Vent

Pipe Diameter table and Exhaust Vent Pipe table for

additional details.

Installing Exhaust Vent Pipe

Install the vent pipe with a minimum downward slope

(from the unit) of 1/4-inch per foot (horizontal venting

only). Securely suspend the pipe from overhead

structures at points no greater than 3 feet apart.

The minimum vent length is 5 feet for horizontal and

10feet for vertical. The maximum vent length is 70 feet.

The total equivalent vent length must include elbows.

The equivalent length of a

4 inch elbow is 6feet and

the equivalent length of a

6inch elbow is 10 feet.

Attach the vent terminal

to the end of the exhaust pipe.

Vent Pipe Diameter

Select the vent pipe

diameter. Use only the

specified pipe diameter.

Standard Indoor Venting - Vertical

Standard Indoor Venting - Horizontal

Vent

Length

Minimum

(feet)

Maximum

(feet)

Horizontal 5 70

Vertical 10 70

Furnace Size

(MBH)

Exhaust Pipe

Diameter (inches)

75-175 4

200-400 6

A = 12 inch minimum

Air Inlet

A

Exterior

Wall

Exhaust

Vent

Terminal

Pitch vent pipe

downward

from furnace

¼ inch per foot

EXHAUST

A A

Exhaust Vent

Terminal

EXHAUST

A = 12 inch minimum

B = 12 inch minimum,

but should size

according to expected

snow depth

Air Inlet

B

Roof Line

®

Loading...

Loading...