®

Sidewall Propeller Fans 1

Installation, Operation and Maintenance Manual

Please read and save these instructions for future reference. Read carefully before attempting to assemble, install,

operate or maintain the product described. Protect yourself and others by observing all safety information. Failure

to comply with these instructions will result in voiding of the product warranty and may result in personal injury

and/or property damage.

Only qualified personnel should install this fan.

Personnel should have a clear understanding of these

instructions and should be aware of general safety

precautions. Improper installation can result in electric

shock, possible injury due to coming in contact with

moving parts, as well as other potential hazards.

Other considerations may be required if high winds

or seismic activity are present. If more information is

needed, contact a licensed professional engineer before

moving forward.

1. Follow all local electrical and safety codes, as

well as the National Electrical Code (NEC) and the

National Fire Protection Agency (NFPA), where

applicable. Follow the Canadian Electric Code

(CEC) in Canada.

2. The rotation of the propeller is critical. It must be

free to rotate without striking or rubbing any

stationary objects.

3. Motor must be securely and adequately grounded.

4. Do not spin fan propeller faster than max cataloged

fan RPM. Adjustments to fan speed significantly

affects motor load. If the fan RPM is changed, the

motor current should be checked to make sure it is

not exceeding the motor nameplate amps.

5. Do not allow the power cable to kink or come in

contact with oil, grease, hot surfaces or chemicals.

Replace cord immediately if damaged.

6. Verify that the power source is compatible with

the equipment.

7. Never open access doors to a duct while the fan

is running.

DANGER

Always disconnect, lock and tag power source before

installing or servicing. Failure to disconnect power

source can result in fire, shock or serious injury.

CAUTION

When servicing the fan, motor may be hot enough

to cause pain or injury. Allow motor to cool

before servicing.

CAUTION

Precaution should be taken in explosive atmospheres.

Document 471755

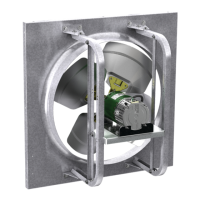

Sidewall Propeller Fans

Belt Drive and Direct Drive

Exhaust, Supply, Filtered Supply and Reversible

General Safety Information

Axial Propeller Wall Fans

Axial propeller wall fans are ideal for factory and warehouse applications

where high volumes of air and low pressures are required. From general

ventilation to industrial duty, the range of construction and performance

capabilities offered represent the most comprehensive sidewall propeller fan

line in the industry.

Wall mounted fans include both direct- and belt-driven fans with various

impeller styles for exhaust, supply, filtered supply, and reversible applications.

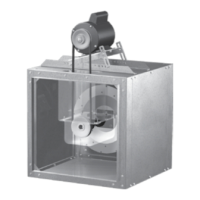

Filtered Supply

Optional filtered supply wall housings are designed with

the draw-thru concept to achieve the highest filter and fan

efficiencies. Permanent 2-inch (51 mm) washable filters

are accessed through a bolted panel and can be easily

removed for cleaning.

Models AER, SE1, SS1, SE2, SS2, SCR3, SBE-1, SBS-1, SBE-2, SBS-2, SBE-3, SBS-3, SBCE, SBCS, SBCR

Models SCE3, SCS3 (Mexico Only)