(Technical regulations for liqueed petroleum gas (TRF); appendix A)

Instructions for using liquid gas cylinders

Operating instructions for liquid gas cylinder systems

(other than propellant gas cylinders and propellant gas cylinder systems)

1. Properties of liquid gas

Liquid gas (propane, butane and mixtures thereof) is a highly ammable, colourless gas with a perceptible odour. It is heavier than oxygen and is ammable with low mixtures of

ambient air. Caution: uncontrolled gas can deagrate or explode.

Liquid gas is pressurised in the cylinder. Protect it from temperatures above 40°C! At higher temperatures, especially when exposed to re, there is a risk of an uncontrolled gas leak and

even to the cylinder bursting.

2. Conduct in the event of malfunctions and leaks: in the case of re:

(e.g. smell of gas, noise of escaping gas): (in buildings/vehicles) additionally:

Notify the re department % 112!

Close the cylinder valve imme-

diately

(clockwise)!

Extinguish any naked ames!

Contact a specialist!

Do not smoke!

Do not actuate any electrical

switches!

Do not use the telephone!

Open windows and doors!

Transfer any leaking cylinders outside im-

mediately!

Evacuate the building/vehicle!

Point out the presence of liquid gas cylinders!

If possible, remove cylinders from any area

that is susceptible to re or cool with water if

necessary.

3. Operation of liquid gas cylinder systems

➱ Liquid gas cylinder systems should only be installed, commissioned, modied and checked by specialised companies.

➱ Liquid gas cylinder systems should only be installed in the commercial sector by trained personnel and checked by an appropriately qualied person or, when dealing with certain

cylinder systems, by a person assigned by the contractor (accident prevention regulations (BGV D 34).

➱ The cylinder must be set in an upright position. Cylinders positioned on their side pose a threat of deagration.

➱ The operating instructions provided by the manufacturer of the liquid gas appliance are to be observed carefully by the user for operation and, if necessary, for troubleshooting

measures. Prior to the initial operation, or after making a modication, the operator of a liquid gas cylinder system must be assured of its orderly condition through examination and

certication by a specialised company (commercial systems are to be addressed by a specialised person responsible for the respective commercial sector). The certicates from the

examinations are to be kept by the operator.

➱ If the system is not going to be used for a prolonged period the valves are to be closed; when doing this start from the device shut-o valve towards the cylinder valve. When starting

up the system again the valves are to be opened; when doing this start from the cylinder valve towards the device shut-o valve.

➱ Naked ames and smoking are prohibited in areas where large cylinders are stored and in close proximity to large cylinder systems. The ventilation openings of the installation

area and/or the cylinder cabinet must be kept free.

Warning signs must be applied.

➱ The operator is prohibited from siphoning liquid gas!

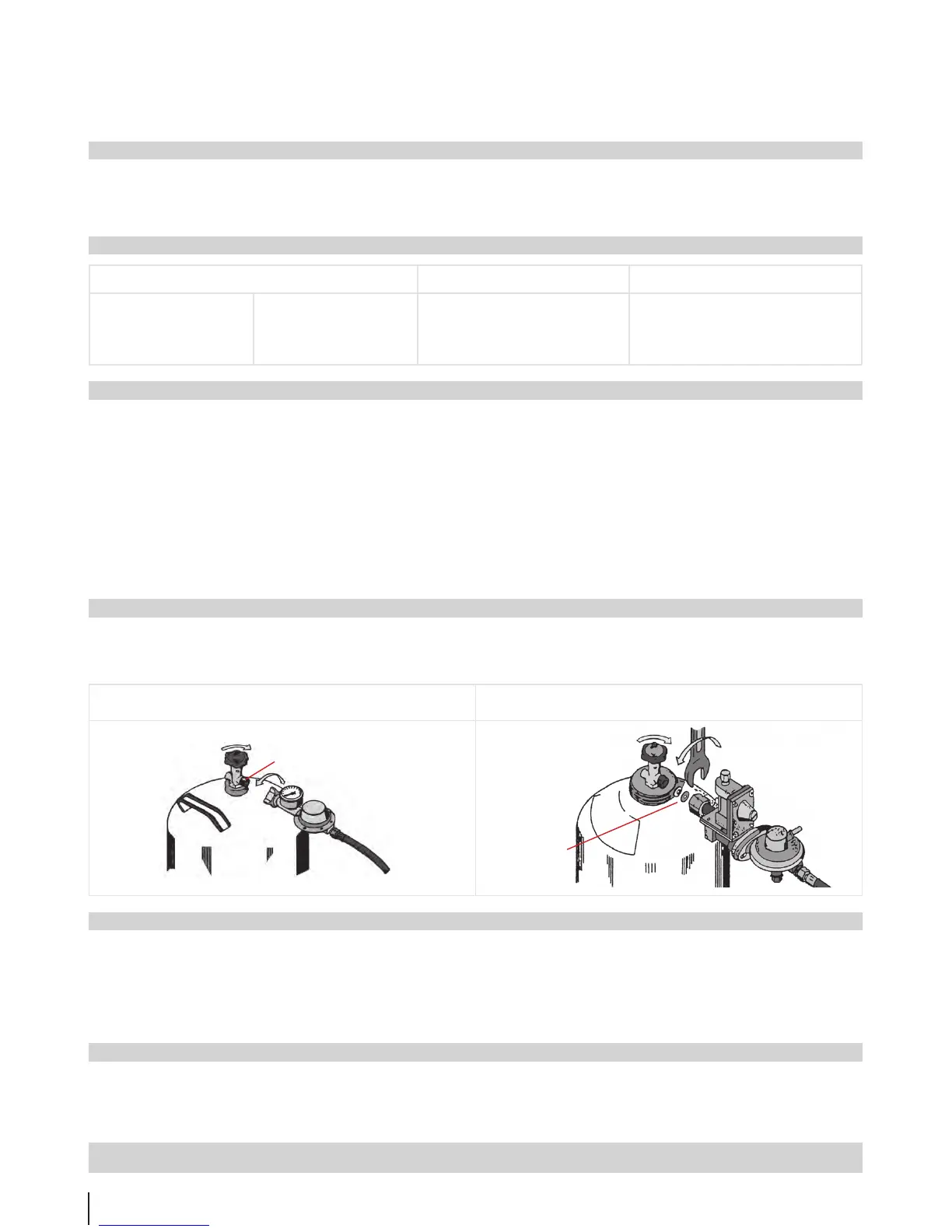

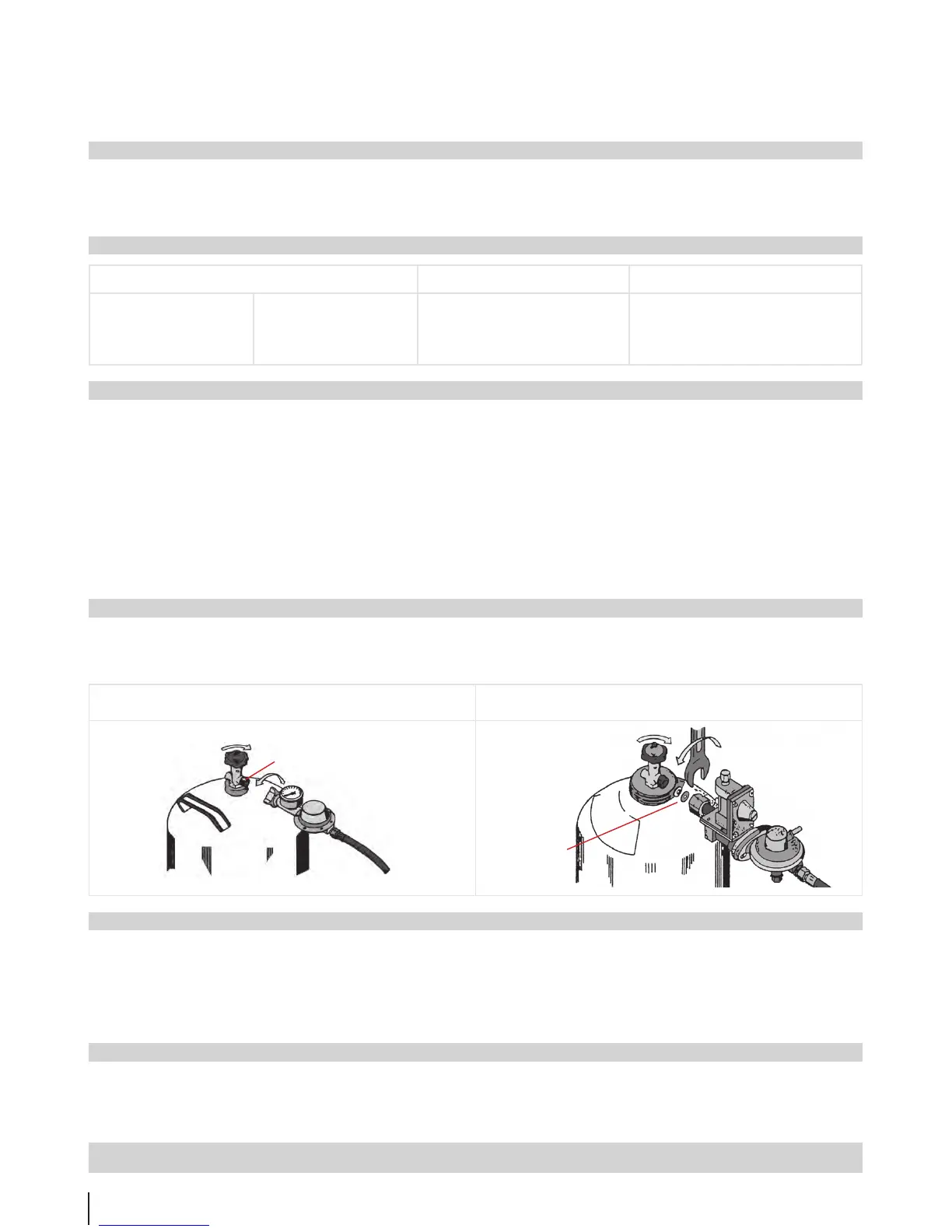

4. Changing the cylinder

➱ When changing the cylinder only loosen the regulator connection after the cylinder valve has been fully closed (clockwise). The pressure regulator must be connected and well

sealed. Pay attention to the existing sealing ring (see diagram) Note left-hand thread! Every time the cylinder is changed the seal of the regulator connection must be tested

using foaming agents (e.g. soapy water).

➱ For multi-cylinder systems: Close the shut-o valve of the container connecting line; set switch to full cylinders.

Regulator connection small cylinder

(5 and 11 kg nominal capacity)

Regulator connection small cylinder

(33 kg nominal capacity)

5. Safety monitoring of liquid gas cylinder systems

Liquid gas cylinder systems are to be examined on a recurring basis. The examinations are to be initiated by the operator:

➱ Fixed systems in buildings with cylinders up to 11 kg nominal capacity: ......................................................................................every 5 years by a specialised company

➱ Fixed systems in buildings with cylinders between 22 and 33 kg nominal capacity: .................................................................... every 10 years by a specialised company

➱ In accordance with accident prevention regulations BGV D 34 for commercial areas (depending on the type of system): ............every 4 years / every 2 years / annually

➱ Systems in vehicles in the private and commercial sector: ............................................................................................................every 2 years

➱ Systems on boats in the private sector:.........................................................................................................................................every 2 years

Components of the system that are subject to wear (e.g. regulators, hoses, etc.) are to be replaced where applicable.

6. Transport and storage

➱ To avoid damaging the valve and to prevent gas leaks full and empty liquid gas cylinders should only be transported and stored with a closed and protected valve (wear nut and cap).

➱ When transporting in vehicles it must be ensured that there is adequate ventilation in the storage area. The cylinders must be secured from shifting during transport.

➱ The cylinders, even if they are empty, should only be stored upright in well-ventilated areas; they should not be stored below ground level (e.g. basements, shafts, etc.), in stairwells,

corridors, passageways, near emergency exits, escape routes and passages between buildings or in their immediate vicinity. No more than two small cylinders should be stored in a

home - and only then in separate rooms (not bedrooms).

Any use of energy involves a risk of danger.

Therefore please observe these user/operating instructions!

Cylinder valve closed

Soft sealing ring in the cylinder valve

Screw the regulator by hand

(left-hand thread)

Cylinder valve

closed

Tighten the regulator with a

spanner (left-hand thread)

Sealing ring (alumini-

um or plastic) on the

regulator side

Loading...

Loading...