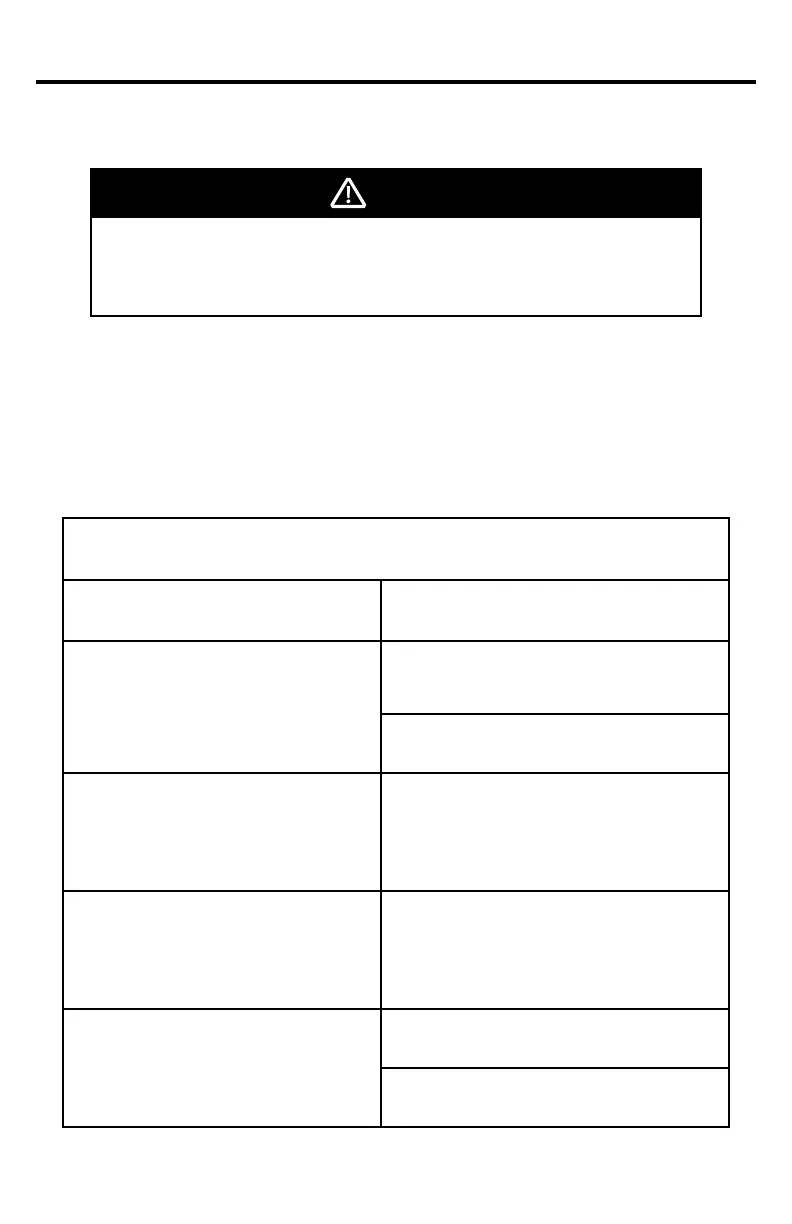

TROUBLESHOOTING

FASTENER DRIVING PROBLEMS

PROBLEM CORRECTIVE ACTION

Fasteners do not drive completely.

AT TOOL: Turn adjustment dial to increase

nail drive depth. Add 2 - 3 drops of air tool

oil to inlet.

AT COMPRESSOR: Increase air pressure.

Do not exceed 120 psi/8.3 bar.

Fasteners do not drive completely

after air pressure is increased.

Driver blade worn or broken.

See dealer for replacement.

Fasteners do not drive completely

when driving in quick succession.

Inadequate air flow. Use larger diameter

hose. Use compressor with larger storage

tank. Keep hose lines short. Check air

hose for kinks or other restrictions.

Fasteners drive too deeply.

AT TOOL: Turn adjustment dial to

decrease nail drive depth.

AT COMPRESSOR: Reduce air pressure.

(Do not reduce below 70 psi/4.8 bar.)

TOOL TROUBLESHOOTING

DANGER

Always disconnect tool from air supply before performing any service

on tool. Correcting a problem while the tool is pressurized may result in

injury from fastener discharge or tool operation.

Your pneumatic fastening tool has been designed for long life and trouble-free

operation. However, if operating problems arise, please use the troubleshooting

information below to determine how to remedy the problem.

16

Loading...

Loading...