English (GB)

15

5.6.4 Connection in the case of unidentified cable

marking/connection

If it is unknown where the individual leads are to be

connected to the mains in order to ensure the correct

direction of rotation, proceed as follows:

Motors wound for direct-on-line starting

Connect the motor to the mains as it is expected to

be right.

Then check the direction of rotation as described in

section 5.5.4 Checking the direction of rotation of the

motor.

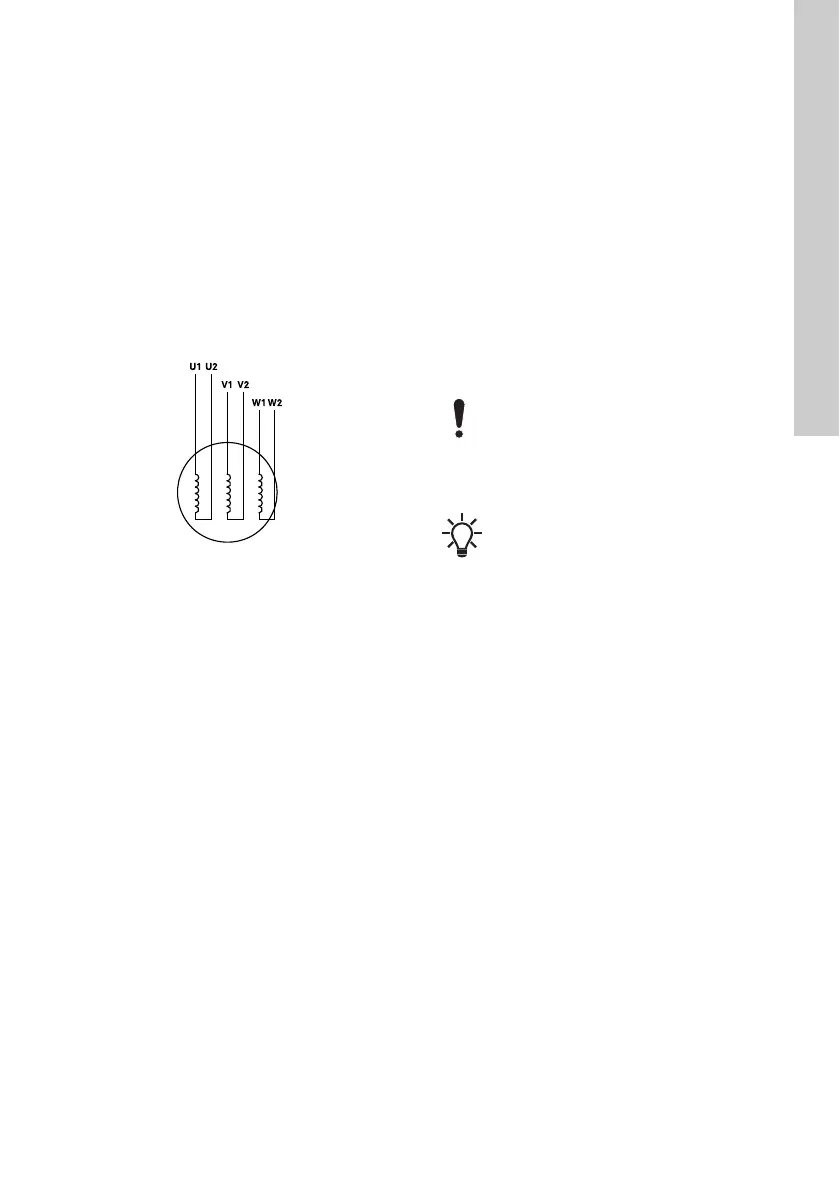

Motors wound for star-delta starting

Determine the windings of the motor by means of an

ohmmeter, and name the lead sets for the individual

windings accordingly: U1-U2, V1-V2, W1-W2. See

fig. 16.

Fig. 16 Unidentified cable marking/connection -

motors wound for star-delta starting

If star-delta starting is required, connect the leads as

shown in fig. 13.

If direct-on-line starting is required, connect the

leads as shown in fig. 14.

Then check the direction of rotation as described in

section 5.5.4 Checking the direction of rotation of the

motor.

5.6.5 Soft starter

Grundfos only recommends the use of soft starters

that control the voltage on all three phases and are

provided with a bypass contact.

Ramp time: Maximum 3 seconds.

For further details, please contact your soft starter

supplier or Grundfos.

5.6.6 Frequency converter

Three-phase MS asynchronous submersible motors

can be connected to a frequency converter.

Three-phase MS6000P synchronous submersible

motors must be connected to a frequency converter

of VSI type and an IPM-ready sine wave filter.

MMS motors with PE/PA can be connected to a

frequency converter.

To avoid EMC problems, it is required to use

shielded cables between the frequency converter

and the sine wave filter, and in EMC sensitive

installations from the sine wave filter to the entrance

of the borehole.

The cable shield must be connected to the sine wave

filter and the borehole lining, if the latter is

conductive.

For asynchronous motors:

Permissible frequency ranges:

• 30-50 Hz

• 30-60 Hz.

Ramp time: Maximum 3 seconds from standstill to

minimum frequency and vice versa.

For synchronous motors MS6000P:

Permissible frequency ranges:

• 55-100 Hz

• 55-120 Hz.

Ramp time: Maximum 3 seconds from standstill to

minimum frequency and vice versa

Depending on the type, the frequency converter may

cause increased acoustic noise from the motor.

Furthermore, it may expose the motor to detrimental

voltage peaks. This can be prevented by installing an

LC filter, or a sine wave filter between the frequency

converter and the motor. Grundfos recommends that

a sine wave filter be used in all SP installations with

voltages above 380 V.

For further details, contact your frequency converter

supplier or Grundfos.

TM00 1367 5092

During frequency converter operation, it is

not advisable to run the motor at a

frequency higher than the rated frequency

(50 or 60 Hz). In connection with pump

operation, it is important never to reduce

the frequency (and consequently the

speed) to such a level that the necessary

flow of cooling liquid past the motor is no

longer ensured.

To enable monitoring of the motor

temperature, Grundfos recommends that a

Pt100 or a Pt1000 be installed.

Loading...

Loading...