7. Service

PNEG-1456 1 and 2 Fan Vision Series Portable Dryers 43

12. Inspect the entire dryer for loose, worn or damaged parts. Include check of auger flighting, metering

rolls and other internal parts. Check that temperature sensors within the air plenum chamber are

secured within insulated clamps and do not chafe on other metal parts.

13. Make sure all dryer guards and warning decals are securely installed. Ensure that guards do not

interfere with moving parts. If guards or warning decals are missing, contact your dealer for a

free replacement.

14. Test fire the dryer several weeks ahead of the drying season. Check for possible gas leaks.

(See Page 18.)

NOTE: If on site bearing lubrication is to be performed, see lubrication instructions for ball bearing

motors. To keep motor bearings properly lubricated and dispel any accumulation of moisture

within the windings, the fan and auger motors should be operated for 15 to 30 minutes

each month.

Lubrication Procedure

If the motors are equipped with an Alemite fitting, clean the tip of the fitting and grease with a grease gun.

Use 1 or 2 full strokes on motors in NEMA 215 frame and smaller. Use 2 to 3 strokes on NEMA 254 through

NEMA 365 frame. Use 3 to 4 strokes on NEMA 404 frames and larger. On motors with drain plugs, remove

drain plugs and operate motor for 20 minutes before replacing drain plug. On motors equipped with slotted

head grease screw, remove screw and apply grease tube to hole. Insert 5 to 8 cm length of grease string

into each hole on motors in NEMA 215 frame and smaller. Insert 8 to 13 cm length on larger motors. On

motors with grease drain plugs, remove plug and operate motor for 20 minutes before replacing drain plug.

NOTE:

All of the auger and metering roll bearings are lifetime lubricated and do not require service lubrication.

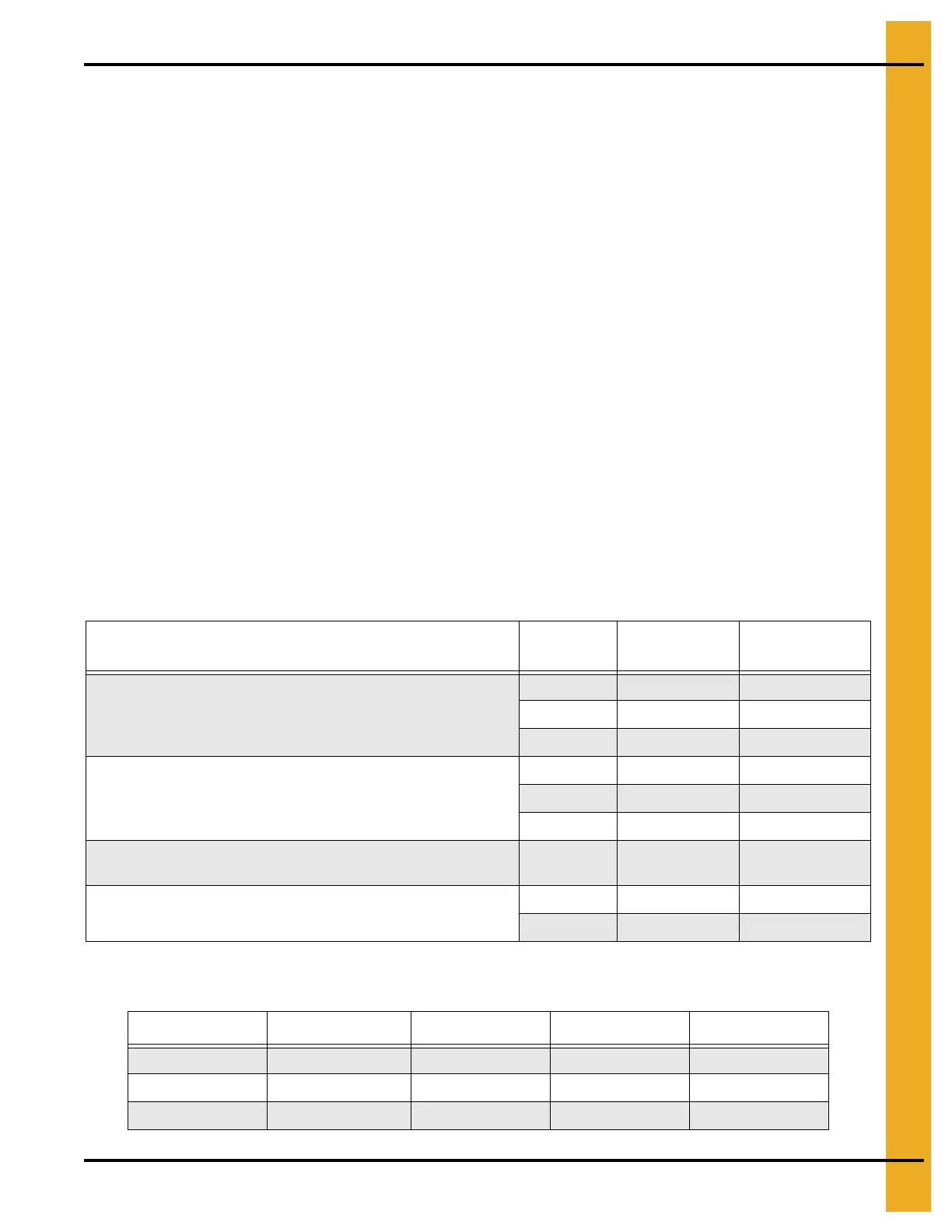

Suggested Lubrication Schedules*

Suggested Lubricants

Hours of Service per Year HP Range kW Range

Suggested Lube

Interval

5000

1/8 to 7-1/2 0.1 to 5.6 5 Years

10 to 40 7.5 to 29.8 3 Years

50 to 150 37.3 to 111.9 1 Year

Continuous Normal Applications

1/8 to 7-1/2 0.1 to 5.6 1 Year

10 to 40 7.5 to 29.8 3 Years

50 to 150 37.3 to 111.9 9 Years

Seasonal Service (motor is idle for 6 months or more) All All

1 Year - Beginning

of season

Continuous high ambient temperatures, dirty or moist locations,

high vibrations or when shaft gets hot

1/8 to 40 0.1 to 29.8 6 months

50 to 150 37.3 to 111.9 3 months

* The bearings have been lubricated at the factory, thus no lubrication should be added before start-up.

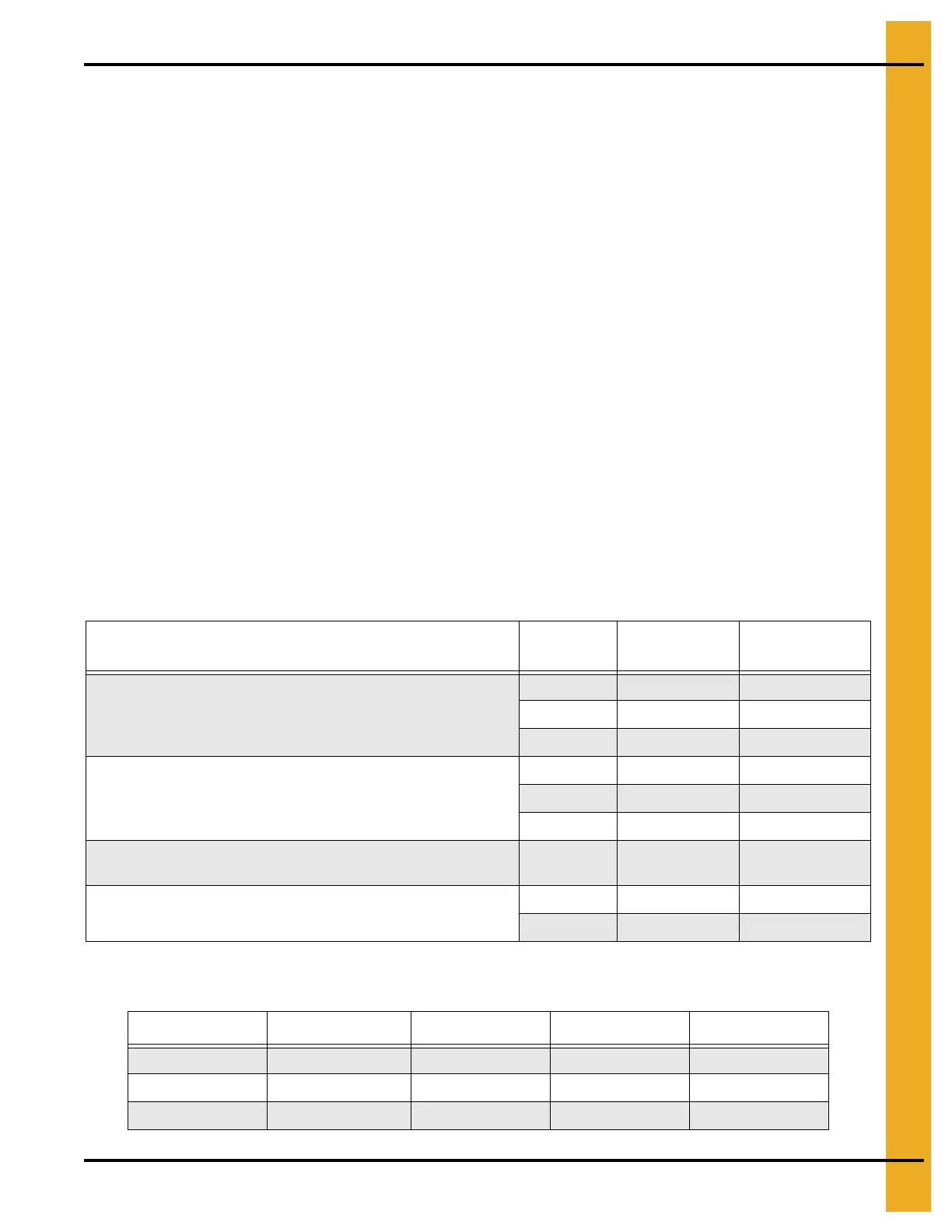

Insulation Class Consistency Type Grease Frame Type

A and B Medium Polyurea Shell Dolium R 215T and Smaller

A and B Medium Polyurea Shell Dolium R 254 and Larger

F and H Medium Polyurea Shell Dolium R All

Loading...

Loading...