3.Connection of refrigerant pipe

During installation,if refrigerant leakage occurs,ventilation measures must be taken.When

fire,hazadous gas will be produced.

After installation,make sure that there is no refrigerant leakage.

Refrigerant,if meeting with heaters and stoves,ect in the room,may produce hazardous gas.

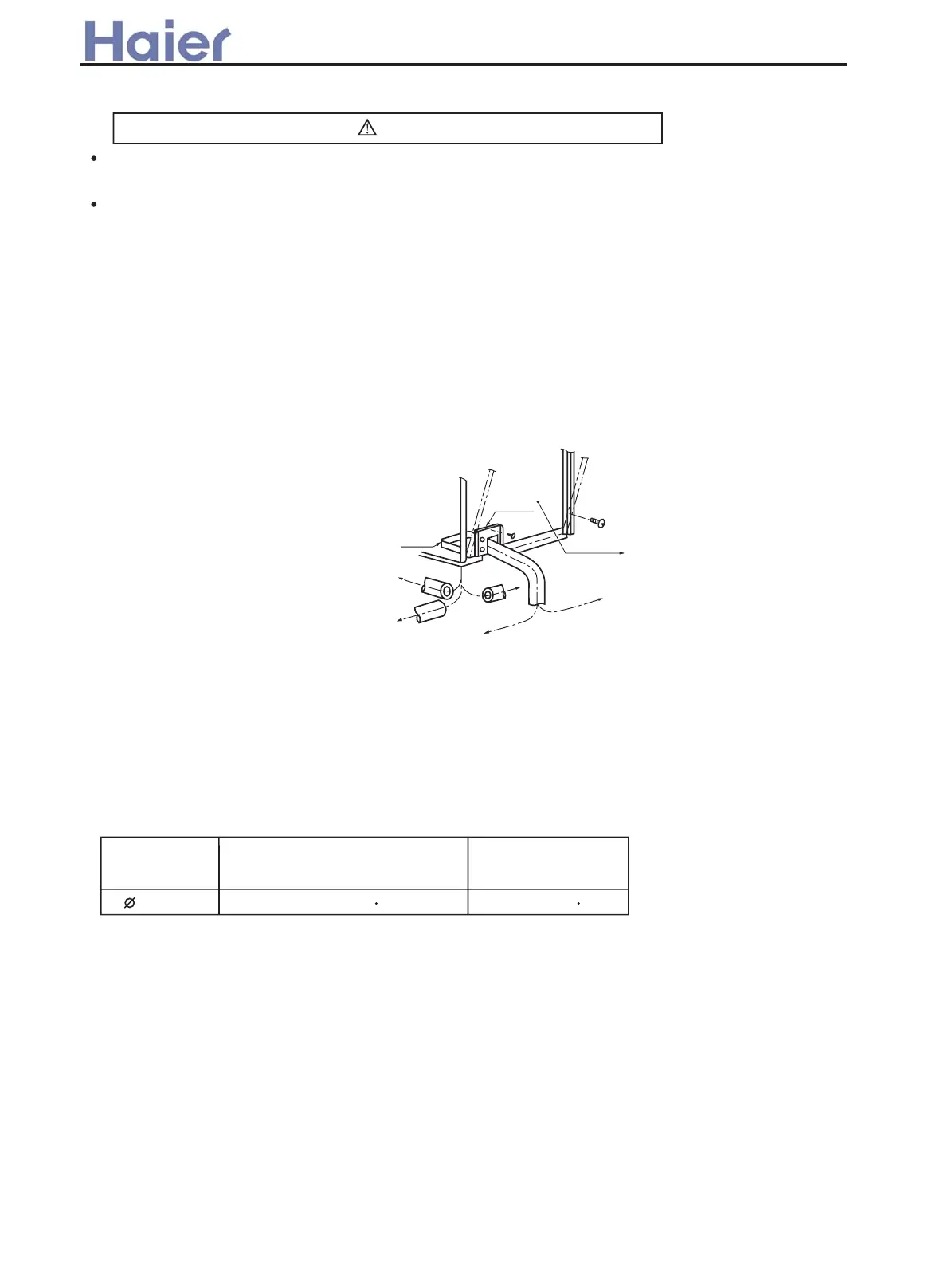

Connection of refrigerant pipe

(1) The joints of the refrigerant pipe are inside the unit.Take off the access hole cover in front of

the unit.

(2) The pipe can be connected from the front or bottom of the outdoor unit.

(3) Remove the L-shaped pipe from the valve by welding and connect the accessory pipe to the

valve.

(4) In the case of front connection,cut the accessory pipe at the height of the fixing panel.Then

an elbow and let it go through the fixing panel.For the convenience of maintenance,

then connect pipe to the right or left.

(5) In the case of bottom connection,join the pipe with accessory pipe through the holes in the

outdoor unit,and connect pipe the left or right or the back.

Warning

Bottom plate

Tube to the tight

Tube to the back

Access hole cover

M4

M6

Tube fixing

panel

Tube to the left

Tube to the left

Tube to the tight

refrigerant meets with

join the pipe with

bend the pipe down (once) and

base plate of the

(6) During welding,the gas pipe valve must be cooled down with a wet cotton cloth.

During welding of the distribution pipe

1.In case of brazing weld of joint,nitrogen must be filled in the pipe to prevent oxidization.

2.The refrigerant pipe should be newly-made and clean.During installation,do not let water and other

into the pipe.

3.Use two spanners to tighten the connecting nut.One spanner will make loose connection.

The torque moment should conform to the specified value.(Refer to the below)

Selection of tube material and size

Determinaltion of tube diameter (Refer to the diagram on next page for steps 1,2,3,4 and 5 below)

1.Tube between the outdoor unit and the first bypass(main tube):

The diameter of the main tube and the outdoor tube should be the same.

2. Tube between bypasses(sub-tube):

The diameter of the sub-pipe is determined according to the total capacity of all the connected

it is larger than the capacity of the outdoor unit,the diameter should be determined

outdoor unit.

Tube diameter

(mm)

12.70

Torque moment for

pre-installation (N.m)

49.0(5.0kgf m)

Install the nonreturn loop and oil trap

Torque moment for

tightening up (N.m)

53.9(5.5kgf m)

substance

indoor units.But if

according the capacity of the

Take AP96NACAEA as an example

Installation

Loading...

Loading...