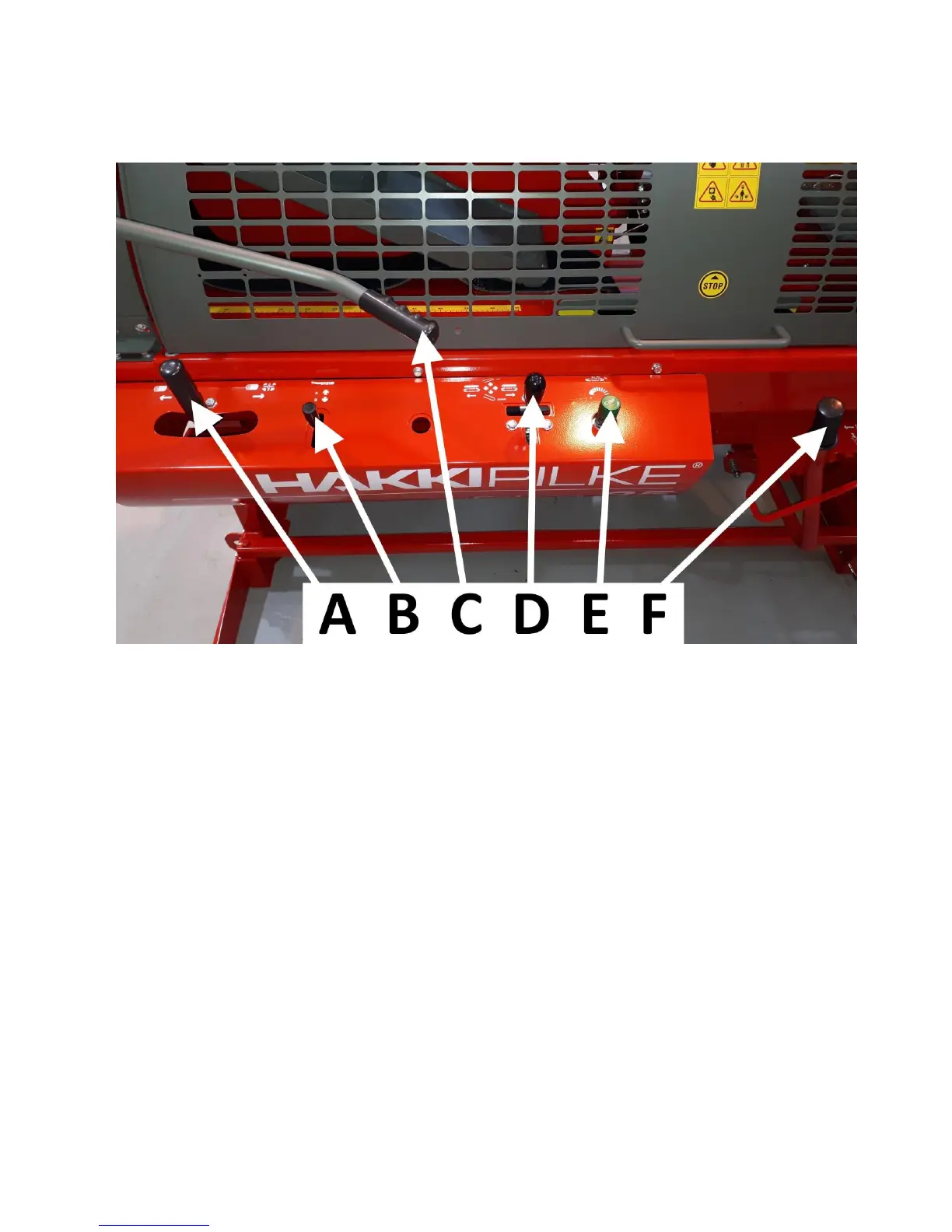

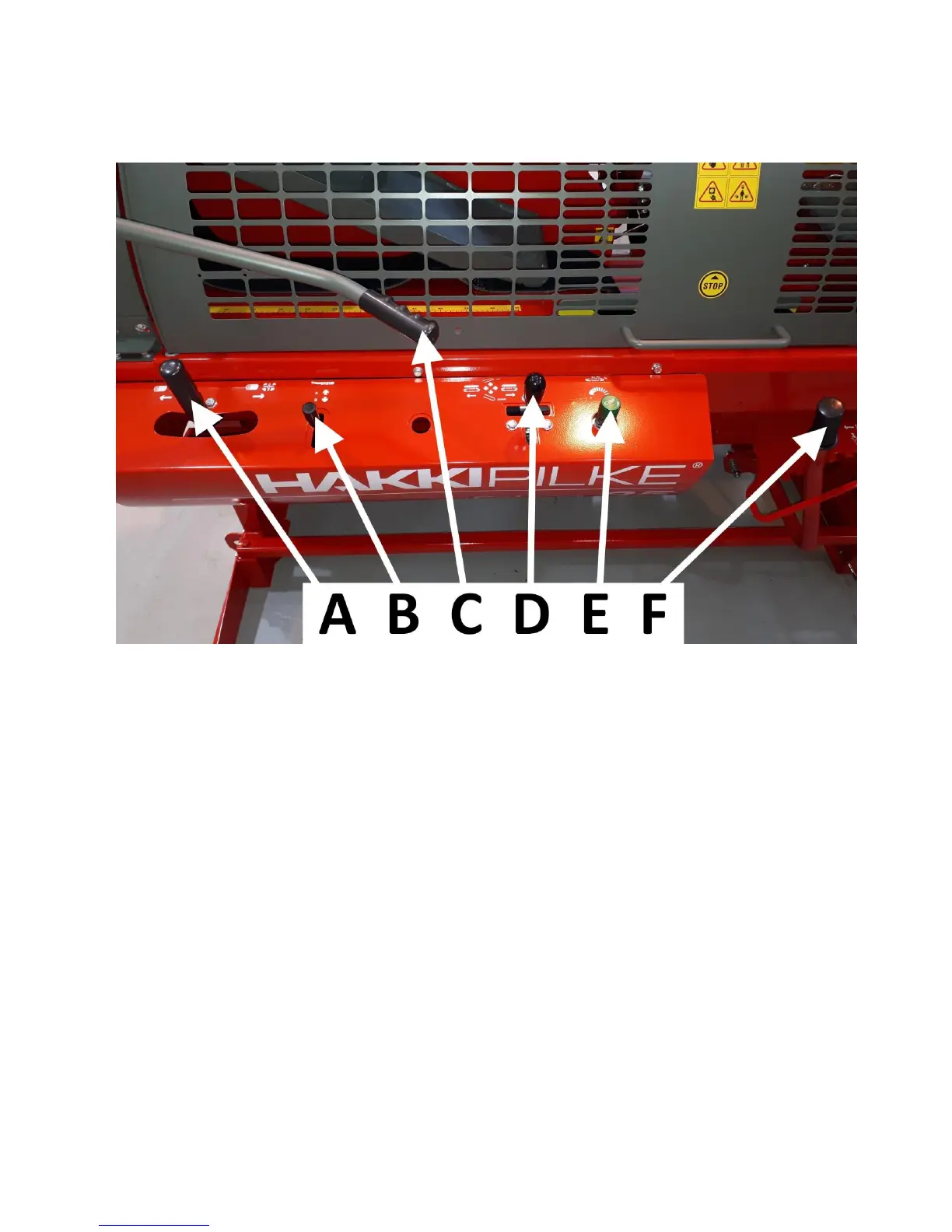

Names and functions of the controls (Figure 11):

A. Splitting cylinder control lever

- Pushing the lever to the left returns the splitting cylinder to the initial position.

- Pushing the lever to the right makes the splitting cylinder perform the splitting motion.

B. Control valve for an auxiliary device, such as a log lifter, (accessory)

C. Log press handle. With the handle, wood can be pressed against the table during sawing in order to make

cutting the wood as safe and stable as possible.

D. Control lever for the saw bar and out-feed conveyor.

- Saw bar up/down: push the lever forward/backward

- In-feed conveyor control right/left: push the lever to the upper right and upper left

E. Out-feed conveyor speed control

- Turning the knob anti-clockwise increases the out-feed conveyor’s speed.

- The belt rotation slows down and eventually stops when the knob is turned clockwise.

F. Height adjustment of the splitting blade.

3.2. Before using the machine

A test run and functional test must always be carried out before the actual operation of the machine. Both the

test run and testing can only be performed by a person who has studied the machine’s manual.

Before the test run, all the components of the firewood processor must be checked. If any faults or wear and tear

that may affect the safe use of the machine are discovered, the processor must not be used until the faulty or

worn component is replaced and safe use can be ensured.

Loading...

Loading...