23

C

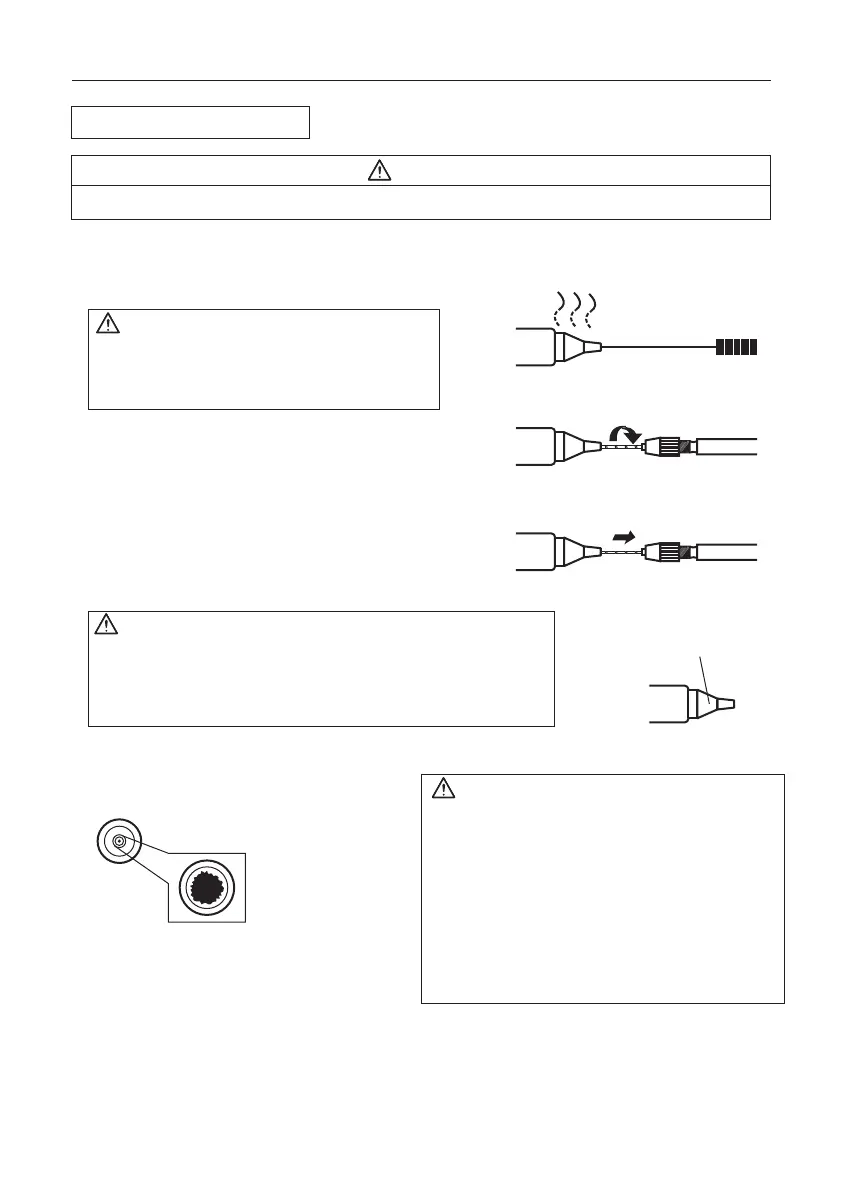

Suction gauge Sign of clogging

CHK

7. MAINTENANCE

WARNING

Since the desoldering tool can reach a very high temperature, please work carefully.

Except when cleaning the nozzle and heating element, ALWAYS turn the power switch

OFF and disconnect the power plug before performing any maintenance procedure.

Properly maintained, the HAKKO FR-400 desoldering tool should provide years of good

service. Efficient desoldering depends upon the temperature, Solder, Flux selection,

and proper routine maintenance. Perform the following service procedures as dictated

by the conditions of the station's usage.

During suction, the gauge indicating suction force

is shown at the bottom of the screen.

If "CHK" appears on the display, check the nozzle

and heater for restrictions.

If the nozzle or heater are clogged, clean or replace

them.

Replacing the filter pipe

Replace the filter pipe as shown following

steps A to C. During operation, the filter

pipe is very hot. Wait until the filter pipe is

cool before replacing the filter or cleaning.

We recommend keeping a second filter pipe

containing new filters handy, and replacing

the installed filter pipe with this secondary

filter pipe.

B. Automatically

goes back

A. Lower the

lock knob

C. Replace the entire filter pipe with

a secondary filter pipe.

CAUTION

The section from the heating element

to the filter pipe is provided with pipes

through which melted solder passes,

so it may become very hot. Be very

careful when handling this section.

CAUTION: HOT AREA

Release Knob

24

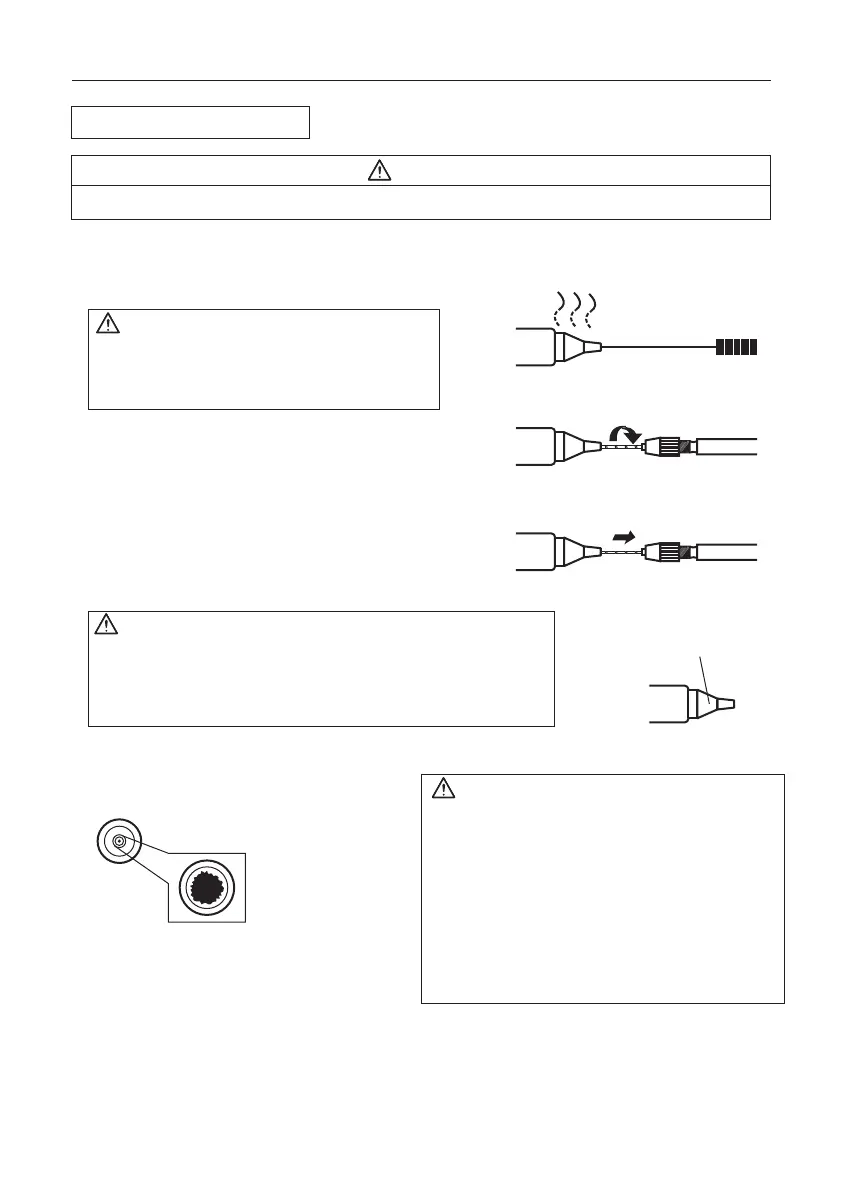

Use the proper size cleaning

pin or cleaning drill for the

nozzle diameter.

Solder plating part

The diameter of the

nozzle has expanded

due to erosion.

The solder plating has come off.

The nozzle hole has eroded.

Cleaning with the nozzle cleaning pin

Cleaning with the cleaning drill

●

Before cleaning

●

After cleaning

The cleaning pin passes

completely through the

hole.

Insert the bit while turning it

clockwise.

Pull the drill bit out straight

without turning it.

Nozzle Maintenance

1. Inspect and clean the nozzle

Turn the power switch ON and let the

nozzle heat up.

● Clean out the hole of the nozzle with the

nozzle cleaning pin.

● If the cleaning pin does not pass through the

hole in the nozzle, clean with the cleaning

drill.

● Check the condition of the solder plating on

the nozzle tip.

● Check visually if the nozzle was eroded.

CAUTION

The handpiece may be extremely hot. During maintenance, please work carefully.

The cleaning pin will not pass through the

nozzle until the solder inside the nozzle is

completely melted.

CAUTION

CAUTION

・If the cleaning drill is forced into the nozzle, the drill bit

could break or be damaged.

・Please use the proper size cleaning pin or cleaning drill

for the nozzle diameter.

CAUTION

・Since erosion cannot be checked visually,

exchange the nozzle if the level of

workability drops.

・The inside and surface of the nozzle hole

is covered in special plating, but erosion

will occur if the nozzle is exposed to high

temperature solders for long periods of

time, disabling it from maintaining normal

temperatures.

* If the nozzle is still in a good condition, put some fresh solder on the nozzle tip to

protect solder plated area from oxidation.

Loading...

Loading...