32

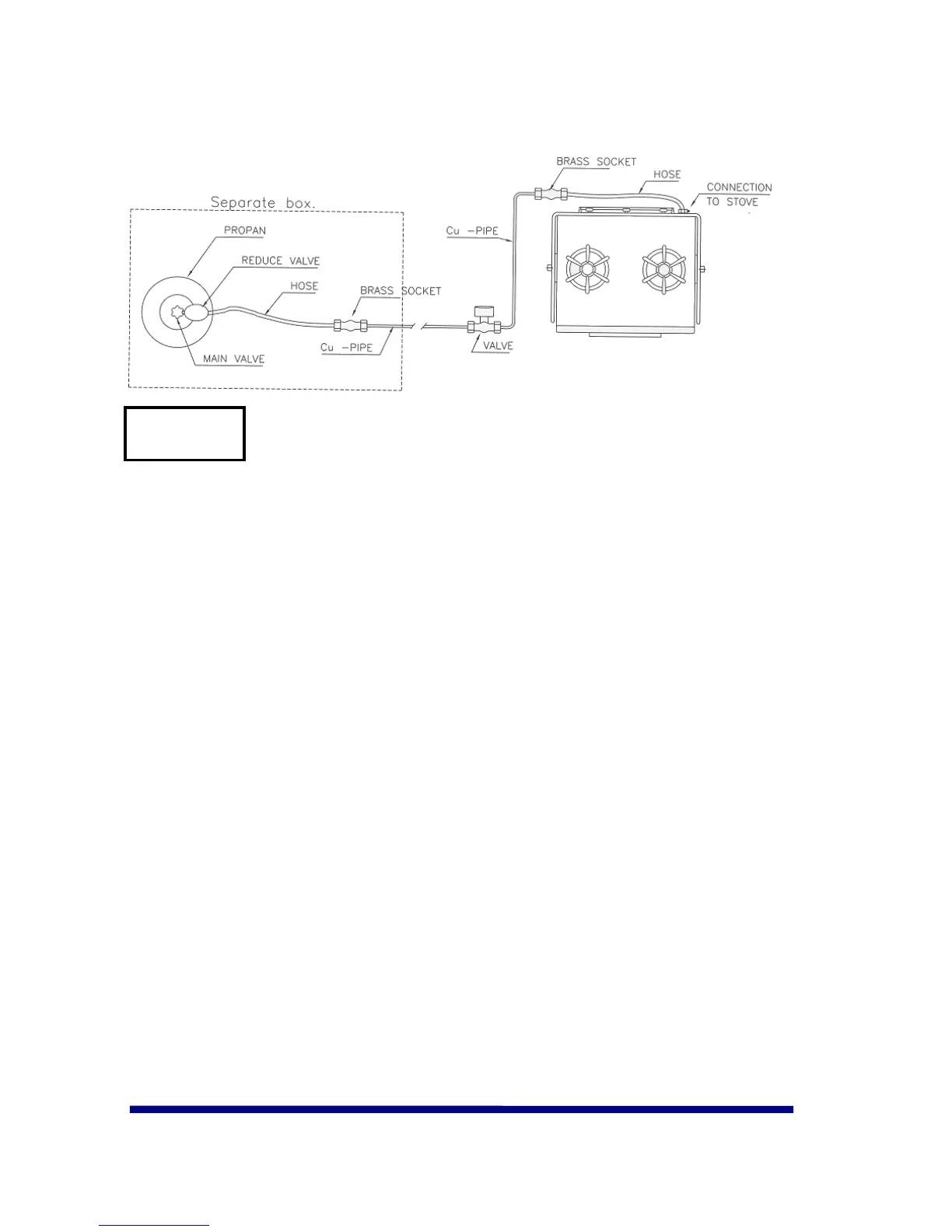

The liquefied petroleum gas system

Read the following advice thoroughly and handle your stove with care,

especially regarding liquefied petroleum gas.

The stove is equipped with an automatic closing mechanism. This means that the gas supply is shut off

automatically after approx. 30 seconds, should the flame go out. To light a burner the control knob

must be pressed and turned clockwise, minimum a quarter of a turn. Keep pressing the knob for 10

seconds after the flame has been lighted.

The stove flames consume oxygen and produce combustion gases. Therefore ventilation is required. If

not, the risk of suffocating can arise. Besides water vapour is generated at the combustion of gas. Make

sure the access to the valve is not blocked so that it can be reached easily by everyone. Always keep the

bottles in the special vented compartment. Storing below deck would be fully irresponsible, as eventual

leaking gas is heavier than air and will collect into the bilge and a direct danger of explosion will

develop.

The burners and the pressure regulator are made for a certain pressure which is labelled on the stove and

on the reduction valve. The pressure of the reduction valve must correspond with the one on the stove.

Close fuel supply line valves and cylinder valve when appliances are not in use. Close valves before

refueling and immediately in an emergency.

Be sure appliance valves are closed before opening cylinder valve.

Test the LPG system for leakage before use. Test all connections for leakage by means of the following:

• Before each use, close appliance valves, open LPG cylinder valve, allow indicated gauge pressure to

stabilize close LPG cylinder valve, observe pressure gauge reading near cylinder valve for three

minutes, pressure gauge reading should remain constant if no leak in the system is present,

If pressure gauge reading falls, leak is present: do not use LPG appliances;

• Routine observation of bubble leak detector (if fitted); or

• Manual leak testing with foam-producing, soapy water or detergent solutions (with appliance burner

valves closed and cylinder and system valves open); foam-producing solutions for leak detection on gas

installations in accordance with EN 14291 meet these requirements;

Danger !

Loading...

Loading...