14

18

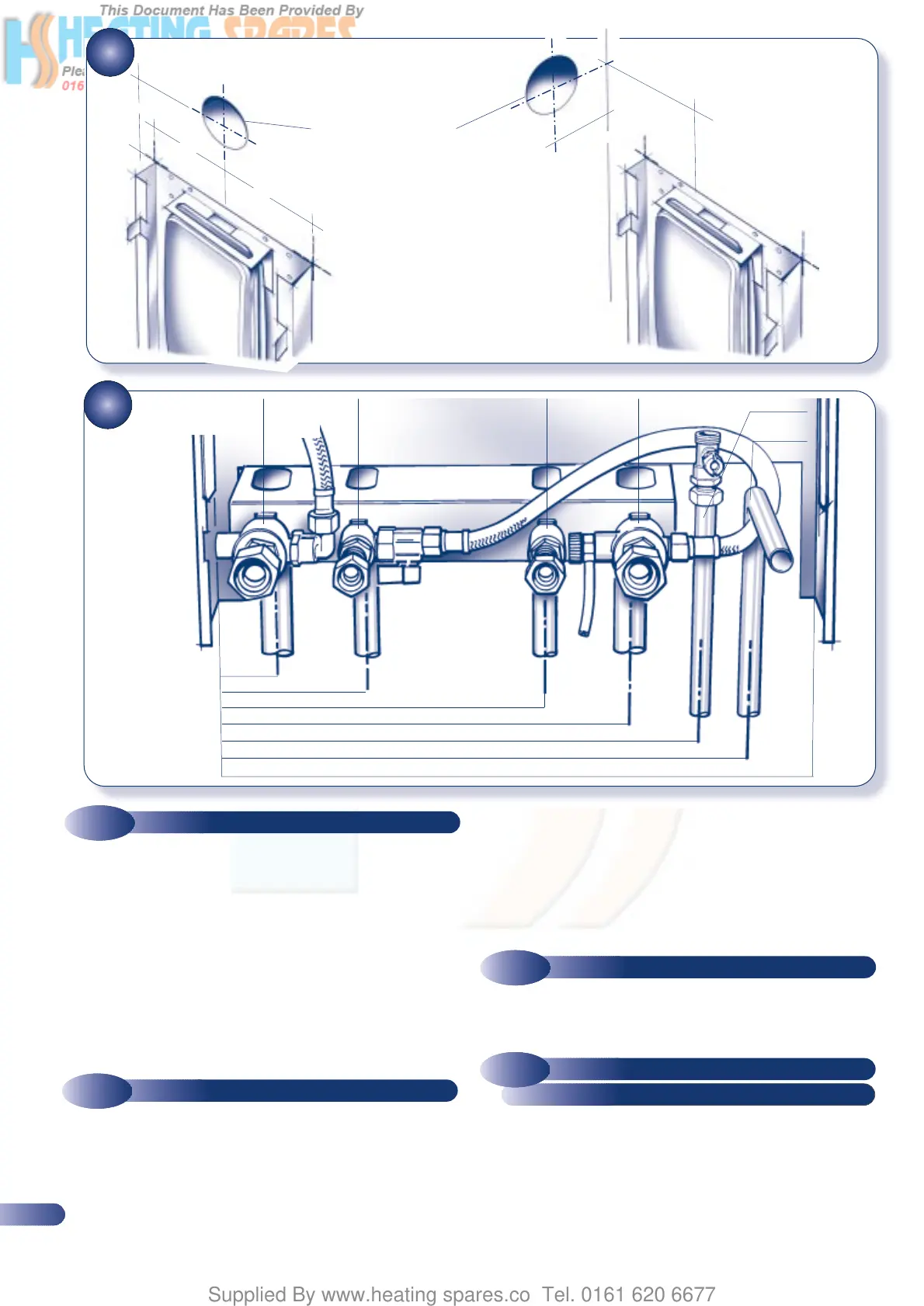

DETERMINING THE POSITION OF THE

AIR/FLUE DUCT HOLE

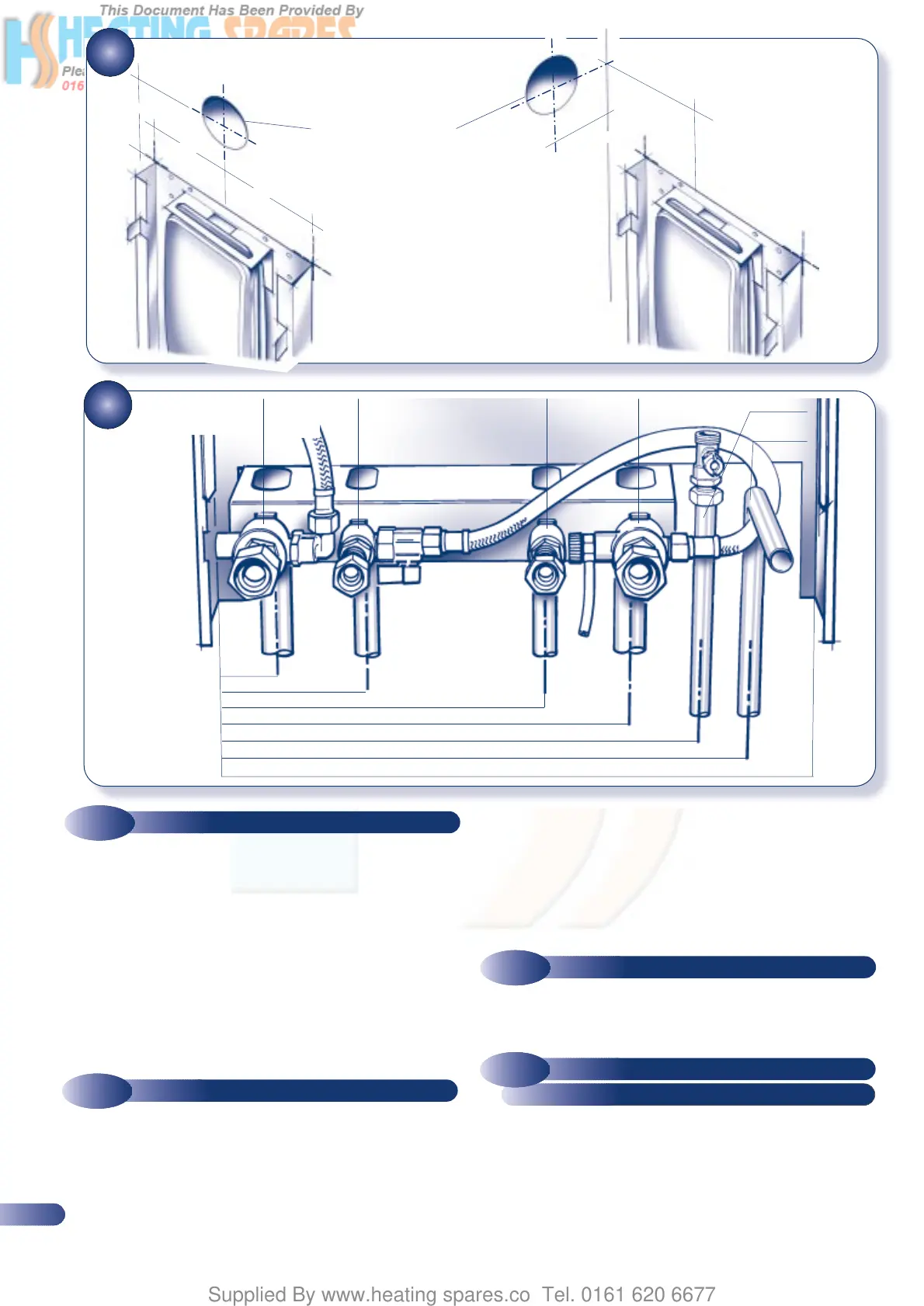

19

a) Connect the central heating system to the boiler flow and

return using the connections shown in Fig. 19.

b) Connect the mains water supply and outlet to the appropriate

connections as shown in Fig. 19.

c) Complete the domestic hot water and central heating system

pipework so that the system can be commissioned before the

boiler is fitted.

d) Commission the central heating system as described in section

5.1, then proceed to section 4.4.

a) Using a

1

/

2

” x 15mm fitting connect the gas supply to the gas

service cock using a suitable jointing compound.

Remove and discard the protective plastic caps on the

appliance rear connections-ensure the nylon seals on the

service connections on the MBC are in place and undamaged.

a) Lift the boiler into position. Position the top of the boiler

approximately 10mm above the top of the MBC and use the

tabs on the MBC to locate the boiler in a horizontal direction,

4.3

SERVICE CONNECTIONS

4.4

FITTING THE BOILER

4.5

GAS CONNECTION

then carefully lower the boiler ensuring locating tabs are

securely engaged (see Fig. 17).

b) Locate and tighten the water connection unions. (Seals are

pre-fitted).

c) Pass the pressure gauge through from the MBC to the plastic

boiler fascia and push into position (See Fig.33).

•

•

•

•

•

225mm

225mm

95mm

18(b) SIDE FLUE

95mm

200mm

•

•

•

•

18(a) REAR FLUE

POSITION OF DUCT HOLE

•

CENTRAL

HEATING

RETURN

•

MAINS WATER

IN

•

DOMESTIC

HOT WATER

OUT

•

CENTRAL

HEATING FLOW

•

•

•

•

•

•

•

•

•

•

GAS SUPPLY

PRESSURE

RELIEF

45mm

•

110mm

•

243mm

•

308mm

•

355mm

•

371mm

•

450mm

SERVICE

CONNECTIONS

•

POSITION

OF MBC

•

POSITION

OF MBC

SERVICE

CONNECTION

PIPES NOT

SUPPLIED

a) Connect a suitable discharge pipe to the pressure relief valve

tube. The pipe should be a minimum diameter of 15mm

copper and should avoid any sharp corners or upward pipe

runs where water may be retained. The discharge pipe must

terminate in an area where any discharge will not cause a

hazard but will be noticed.

4.6

PRESSURE RELIEF VALVE

PIPE CONNECTION

Loading...

Loading...