32

2022_001

6 Troubleshooting

Speak to your dealer if you cannot find the solution for the

problem in the troubleshooting table.

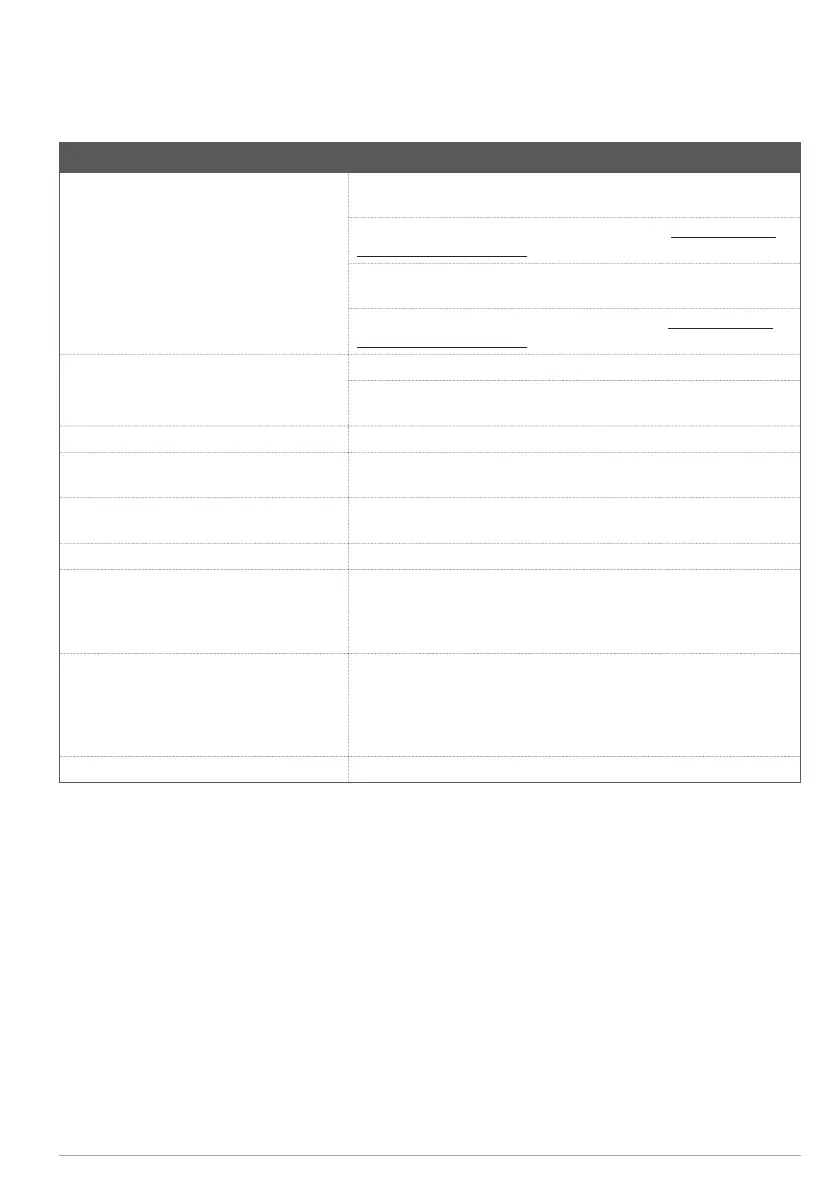

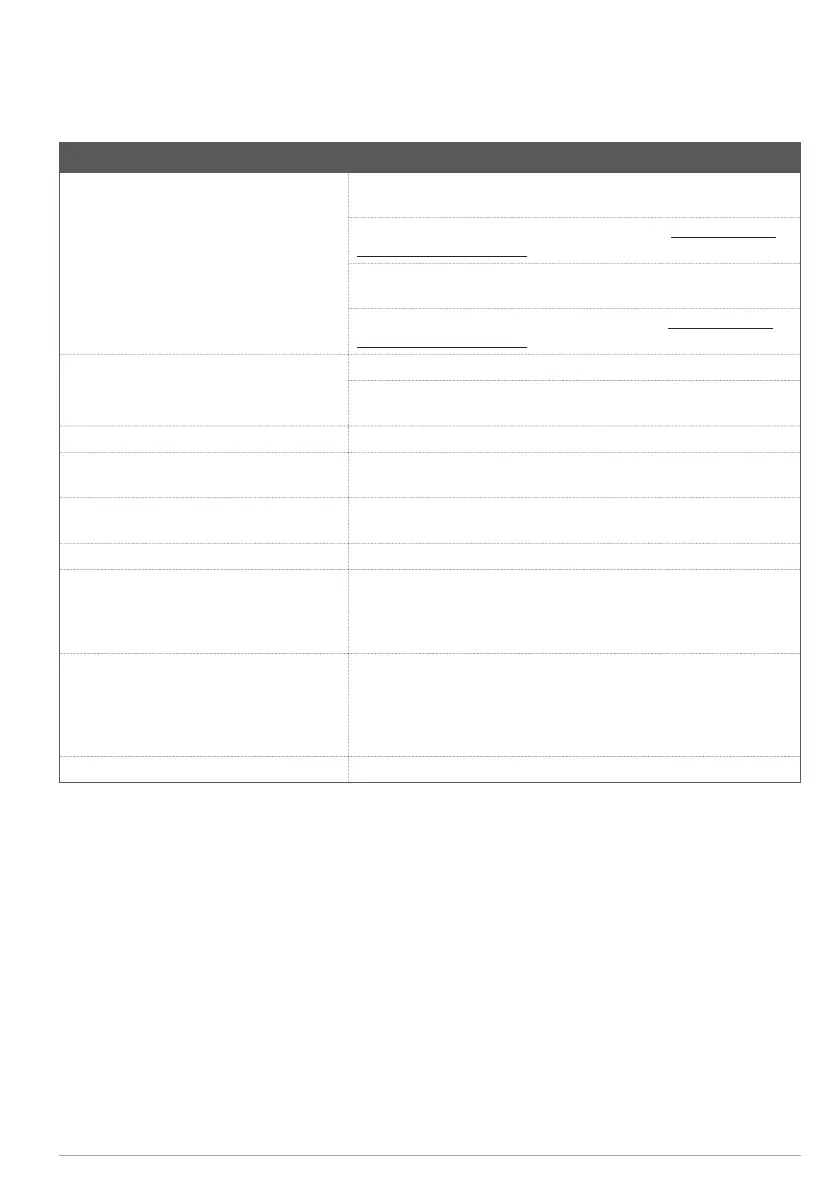

Problem Action

The lifting frames cannot be raised or lowered. Make sure that the hydraulic hoses are not bent, clamped or leak. Release

the hose or repair the leak.

Make sure that the level of the hydraulic fluid. Refer to “4.3.1 To bleed the

hydraulic system” on page 29.

Make sure that the power supply to the hydraulic unit. If it is necessary,

turn the power on

Air has accumulated in the hydraulic system. Refer to “4.3.1 To bleed the

hydraulic system” on page 29.

The lifting frames cannot be lowered. Do a check if the lifting frames are loaded. If not, place a load on them

The product can only operate with a load on the lifting frames. Put a load

on the lifting frames.

The electric power unit gives no pressure. Repair the power unit.

The lifting frames have become stuck at

maximum height with no load.

To lower from maximum height, the lifting frames must be loaded.

The lifting frames cannot be raised from a fully

lowered position.

There must be space between the ground and the load that is to be lifted.

The hydraulic fluid is contaminated. Replace the contaminated hydraulic fluid with new fluid of the same type.

No button is pushed but the lifting frames are

slowly lowered.

Do a check that the lifting frames are locked in 1 of the locking positions. If

not, hydraulic fluid is slowly leaking and the lifting frames are lowered. Do

not leave the product if it is not fully lowered or locked in 1 of the 3 locked

positions.

The couplers are diicult to connect. There is pressure in the hydraulic system. Make sure that the lifting frames

are fully lowered. Push and hold the D button for a few seconds to release

the pressure to return as much hydraulic fluid as possible to the fluid

container. Speak to your dealer if the pressure is so high that it is not

possible to connect the couplers.

Abnormal noise during use. Lubricate the joints with white lithium grease.

Loading...

Loading...