Technical Manual VERSION 2.0 -10-18-2018

13

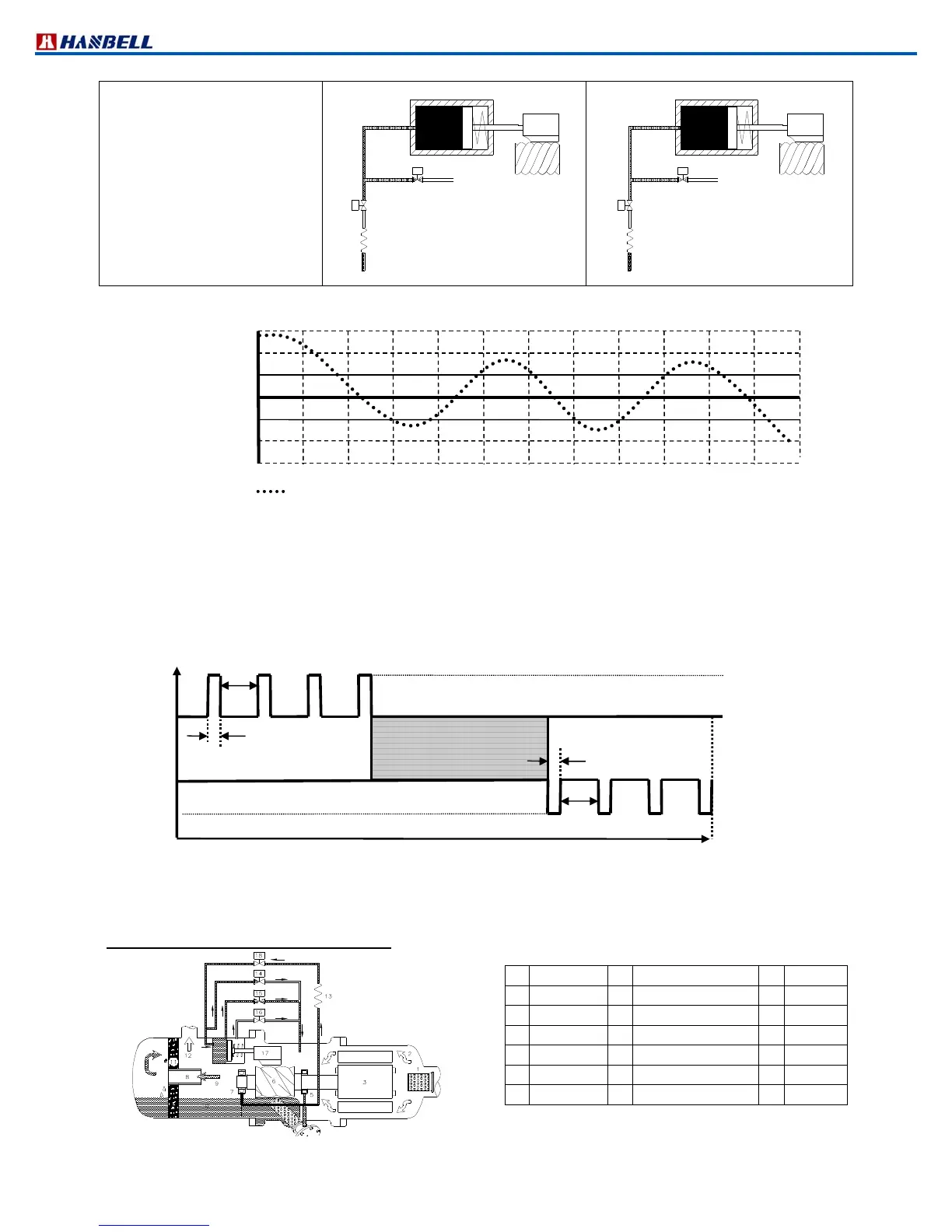

Standard: When both NC SV2

and NC SV1 are not energized,

piston can be held in

stable/holding position.

Option: When NO SV2 is

energized but NC SV1 is not

energized, piston can be held in

stable/holding position.

(N.C. / OFF;Oil bypasses)

(N.C. / OFF; Oil injection stops)

SV1

SV2

STABLE/HOLDING

(N.C. / OFF;Oil bypasses)

(N.O. / ON; Oil injection stops)

SV1

SV2

STABLE/HOLDING

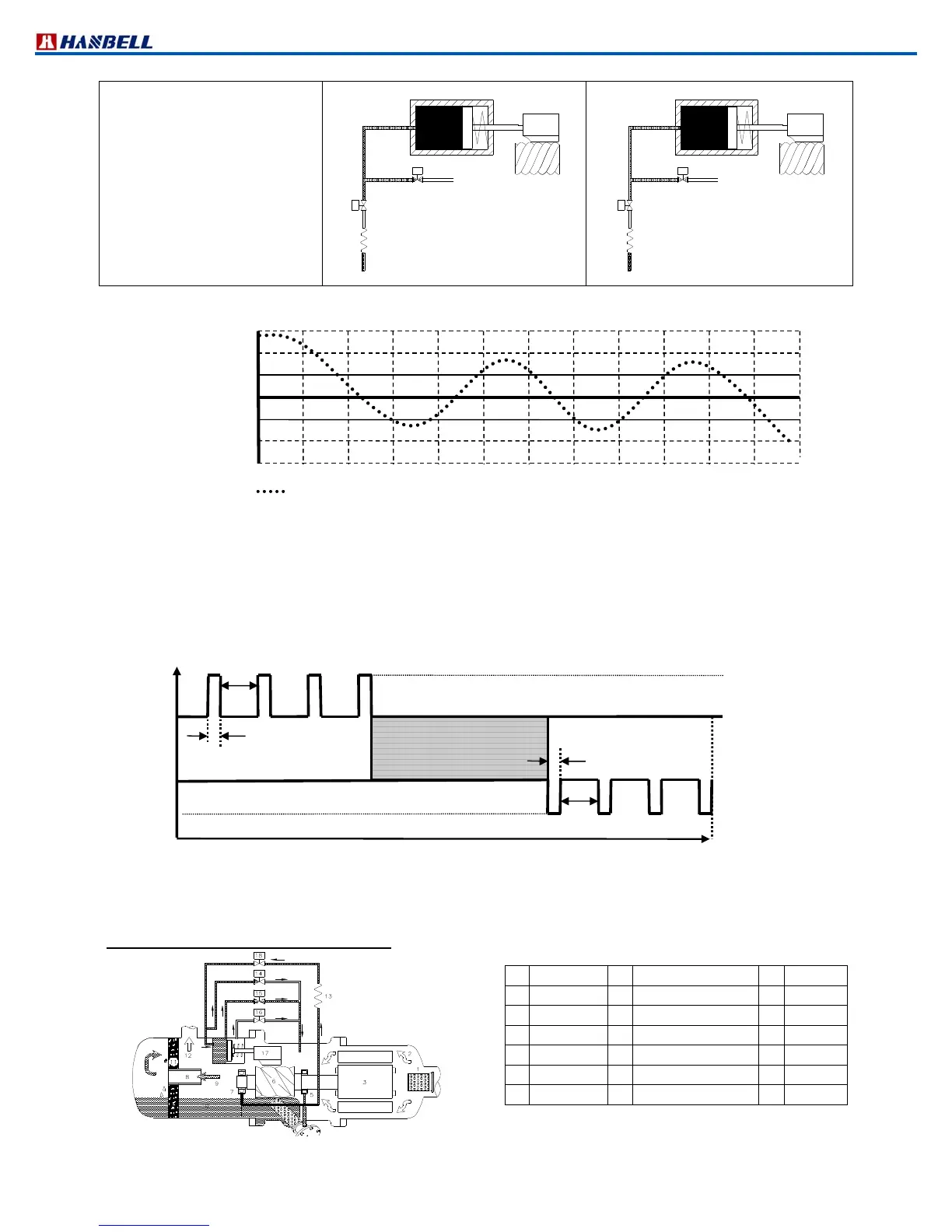

Continuous /stepless capacity control principle

Note: 1. Above T. & T' should be determined by system designer’s experience and end user’s application.

2. Capacity control must be kept at unloading for 1~3 min before start and for 60~90 sec before stop.

Loading/unloading functions

Figure 15 Loading and unloading functions

t

1,

t

3

: Pulse time 1 ~ 1.5 seconds

t

2,

t

4

: Pause time 15 ~ 20 seconds

2.9 Dual capacity control system (optional)

Figure 16 Dual capacity control

No.

Component No.

Component No.

Component

1 Suction filter 7 Discharge bearings 13 Capillary

2

Gas in(low pressure)

8 Oil separator baffle 14 Solenoid valve

3 Motor 9

Gas out(high pressure with oil)

15 Solenoid valve

4 Oil filter cartridge 10 Lubricant 16 Solenoid valve

5 Suction bearings 11 Oil separator cartridge 17 Slide valve

6 Male rotor 12 Gas out (high pressure without oil) 18 Solenoid valve

Set point (target)

Set point T’

Set point + T

U U U U L L L S S S S S

1~3min

U

S

L

Chilled water temperature

Unloading

Stable(holding)

Loading

60~90sec

Chilled Water Temp

.

Time

SV2 Open

SV2 Close

SV1 Close

SV1 Open

t

1

t

2

t

3

t

4

Start

Time

Hanbell can provide compressors with capacity as

shown in the figure 16, and its control logic is the same

as those shown in chapter 2.7 and 2.8.

Loading...

Loading...