Do you have a question about the Hanseatic WQP8-7312D and is the answer not in the manual?

Lists common failure points for the inlet valve and associated error codes.

Procedures for checking the electrical and machine parts of the inlet valve.

Lists common issues with the drain pump and their corresponding error codes.

Steps for checking the electric and machine parts of the drain pump.

Lists common problems with the heater and associated error codes.

Procedure to measure the resistance of the heating element.

Lists common issues with the washing pump and their associated error codes.

Procedures for checking the electrical and machine parts of the washing pump.

Procedure to test the NTC resistance against a temperature table.

Procedure to test the flowmeter's electrical output using a multimeter.

Procedures for inspecting electronic and mechanical safety hoses.

Instructions on how to start and operate the dishwasher's test program.

Step-by-step breakdown of the test program sequence and descriptions.

Flowchart for diagnosing and resolving E1 error (longer inlet time).

Flowchart for diagnosing and resolving E3 error (longer heating time).

Flowchart for diagnosing and resolving E4 error (overflow).

Flowchart for diagnosing E6 error (thermistor open-circuit).

Flowchart for diagnosing E7 error (thermistor short-circuit).

Flowchart for diagnosing E8 error (diverter valve fault).

Analysis and remedies for E1 error related to longer inlet time.

Analysis and remedies for E3 error related to heating or washing pump faults.

Analysis and remedies for E4 error related to overflow.

| Brand | Hanseatic |

|---|---|

| Model | WQP8-7312D |

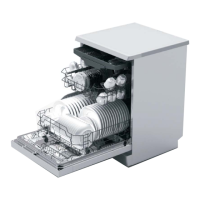

| Category | Dishwasher |

| Language | English |

Loading...

Loading...