7

HARDI NAVIGATOR

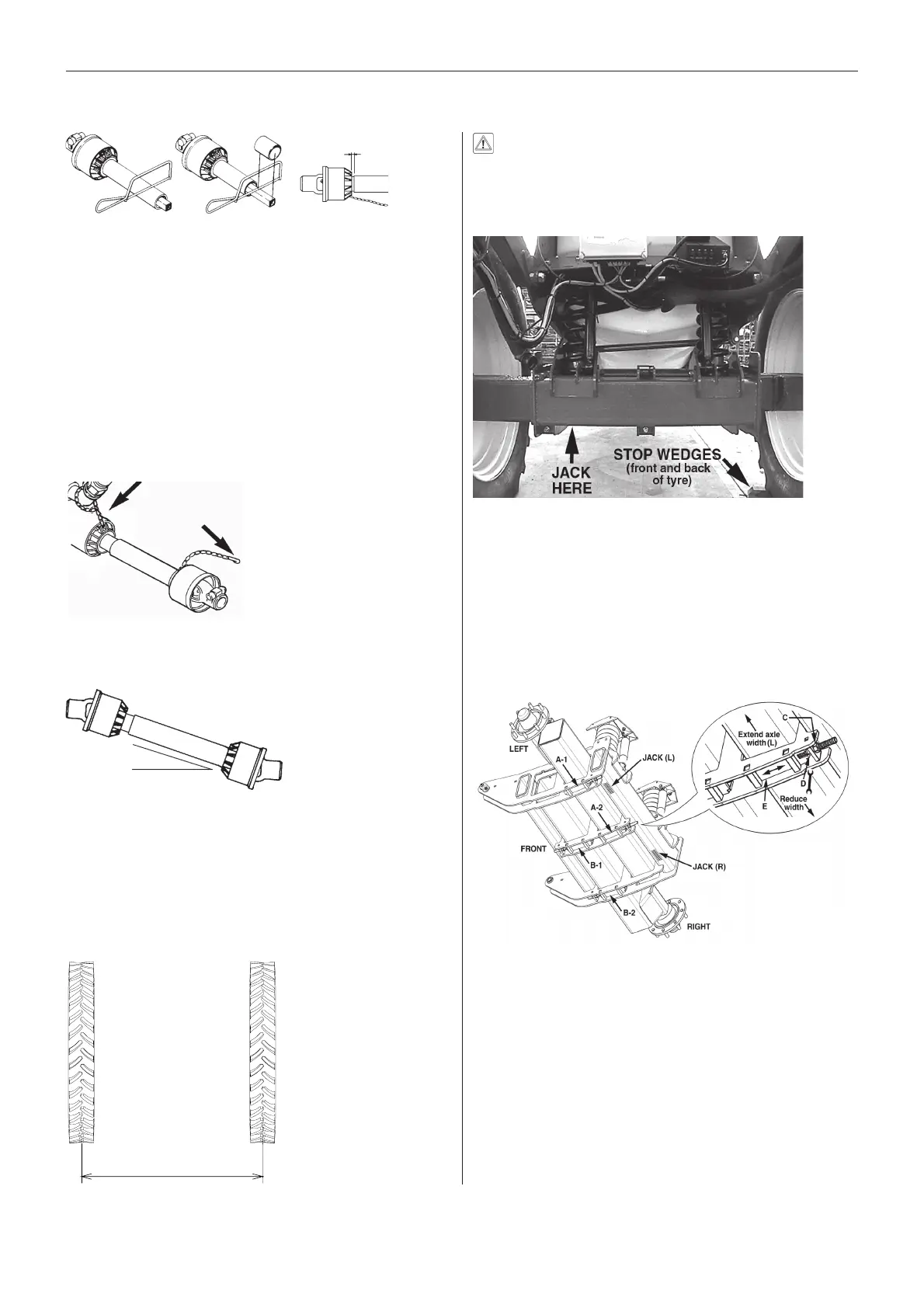

Fig 6

4 Shorten the two separated parts equally. Use a saw

and file the profiles afterwards to remove burrs.

5 Grease profiles. Re-assemble male and female parts.

6 Grease the tractor and sprayer pump PTO shafts.

7 Fit the transmission shaft to the tractor and sprayer

pump PTO shafts:

Push the yoke pin and slide the yoke onto the PTO

shaft. Make sure that the lock engages by pushing

and pulling forwards and backwards. Fit the chains to

prevent protection guards from rotating with the shaft.

NOTE! Please fit the female part marked with a

tractor symbol towards the tractor.

Fig 7

NOTE! To ensure long life of the transmission

shaft try to avoid working angles greater than 25°.

Fig 8

Wheel track

Where an adjustable axle is fitted, the wheel track can

be altered infinitely from 1500 mm to 3000 mm by

extending or retracting the wheel axle, depending on

wheel and suspension options.

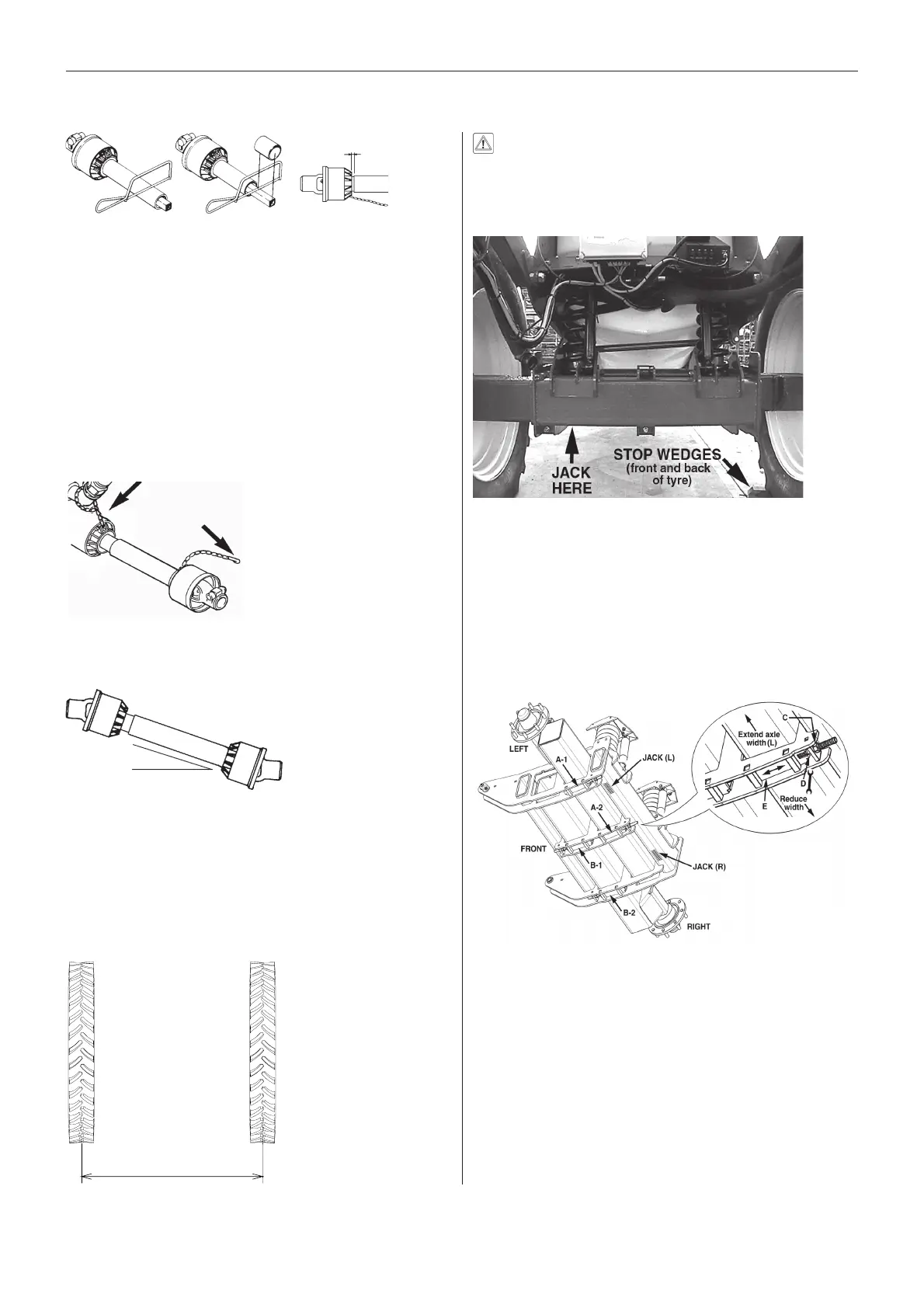

Fig 9

WARNING! It is not permitted to fit dual wheels.

CAUTION! Stability of the sprayer at high speed

can be reduced with narrow wheel tracks.

Wheel track is altered the following way:

Fig 10

1 Measure the correct wheel track (Centre of right hand

tyre to centre of left hand tyre). Extend or retract each

side equally to achieve the desired alteration.

2 Attach sprayer to the tractor and engage tractor

parking brake.

3 Place stop wedges in front of and behind the right

hand wheel. Using suitable heavy duty equipment,

jack up the left hand wheel. Ensure secure support

for the sprayer body.

Fig 11

4 To release axle wedge for the left hand wheel axle

and extend or retract the axle:

Turn Nut C (Fig 11) anti-clockwise to allow

approx. 30 mm clearance.With an open-ended

spanner turn Nut D (Fig 11) against anchor plate

until hold on axle is released. Shift axle to measured

position.

5

To tighten axle wedge and secure axle at required width:

Turn Nut D anti-clockwise to allow movement of

stop wedge.Turn Nut C clockwise against anchor

plate to draw stop wedge up against the axle and

hold it in position. Tighten to torque of 280 Nm,

then lock by re-tightening Nut D.

25°

1500 mm to 3000 mm

MIN 20 mm

Loading...

Loading...