Harman® • P-Series Installation Manual_R18 • 2014 - ___ • 06/1816 3-90-436168i

Harman pellet stoves depend on a combustion fan to pull air

through the unit for combustion. The venting system restricts

the ability of the combustion fan to move the required amount

of air through the unit. A system with too much resistance

will result in incomplete combustion, more frequent required

cleaning and poor unit performance. It is always best to

choose a location for the appliance that will result in a venting

system with the shortest equivalent vent length (EVL).

It is best to have your venting system designed by a Harman

authorizeddealerbeforeyounalize your purchase of an

appliance.

Equivalent Vent Length: The equivalent vent length for

common pellet vent components are:

• 90° Elbows or Tee: 5 EVL Units

• 45° elbow: 3 EVL Units

• Vertical Pipe or Liner: ½ EVL Unit

• Horizontal Pipe or liner: 1 EVL Unit

The total allowable equivalent vent length is:

• 20 EVL for 3” pellet vent pipe or liner

• 30 EVL for 4” pellet vent pipe or liner

Duetothepotentialfor y ash accumulation in horizontal

venting sections, the maximum permissible horizontal venting

length is:

• 4 ft. for 3” & 4” pellet vent pipe.

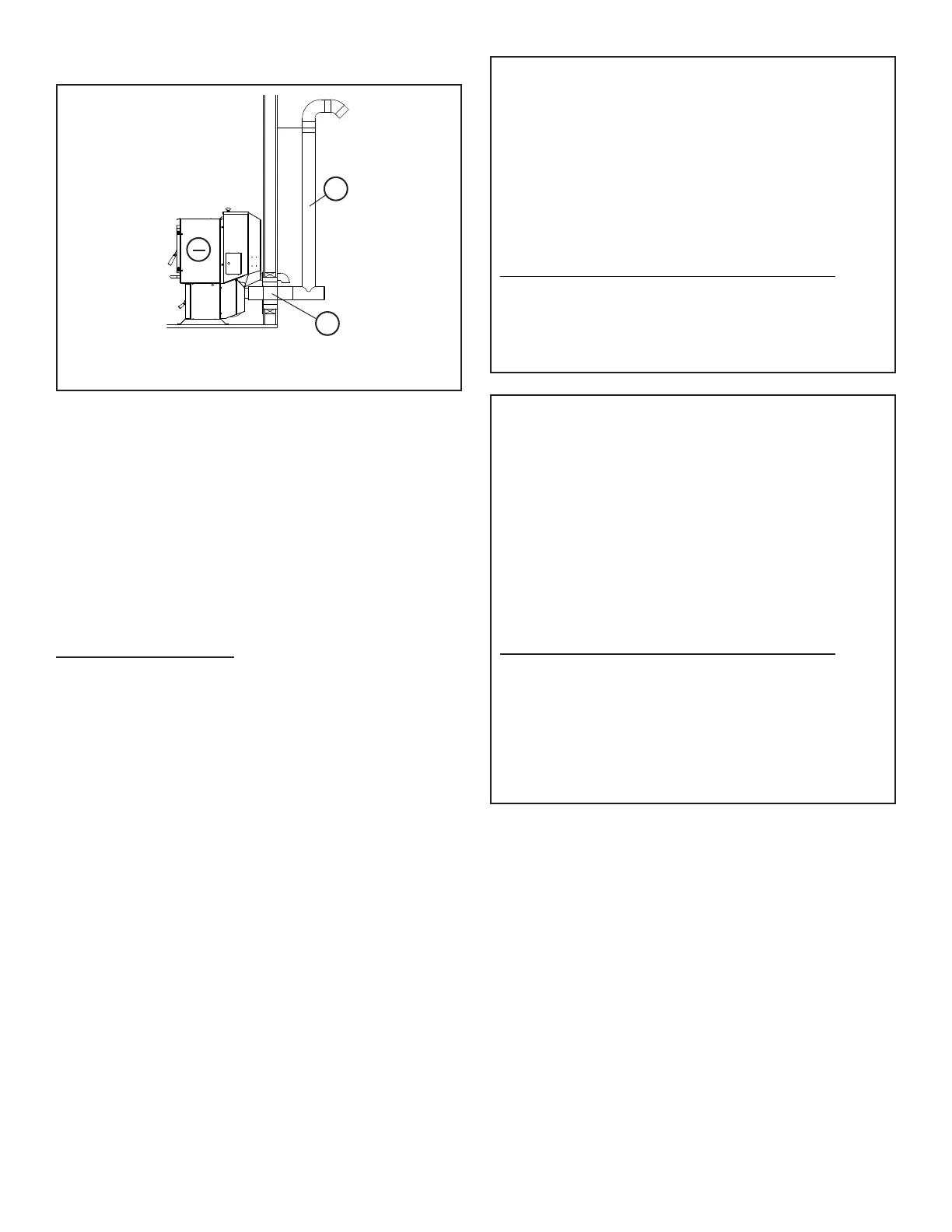

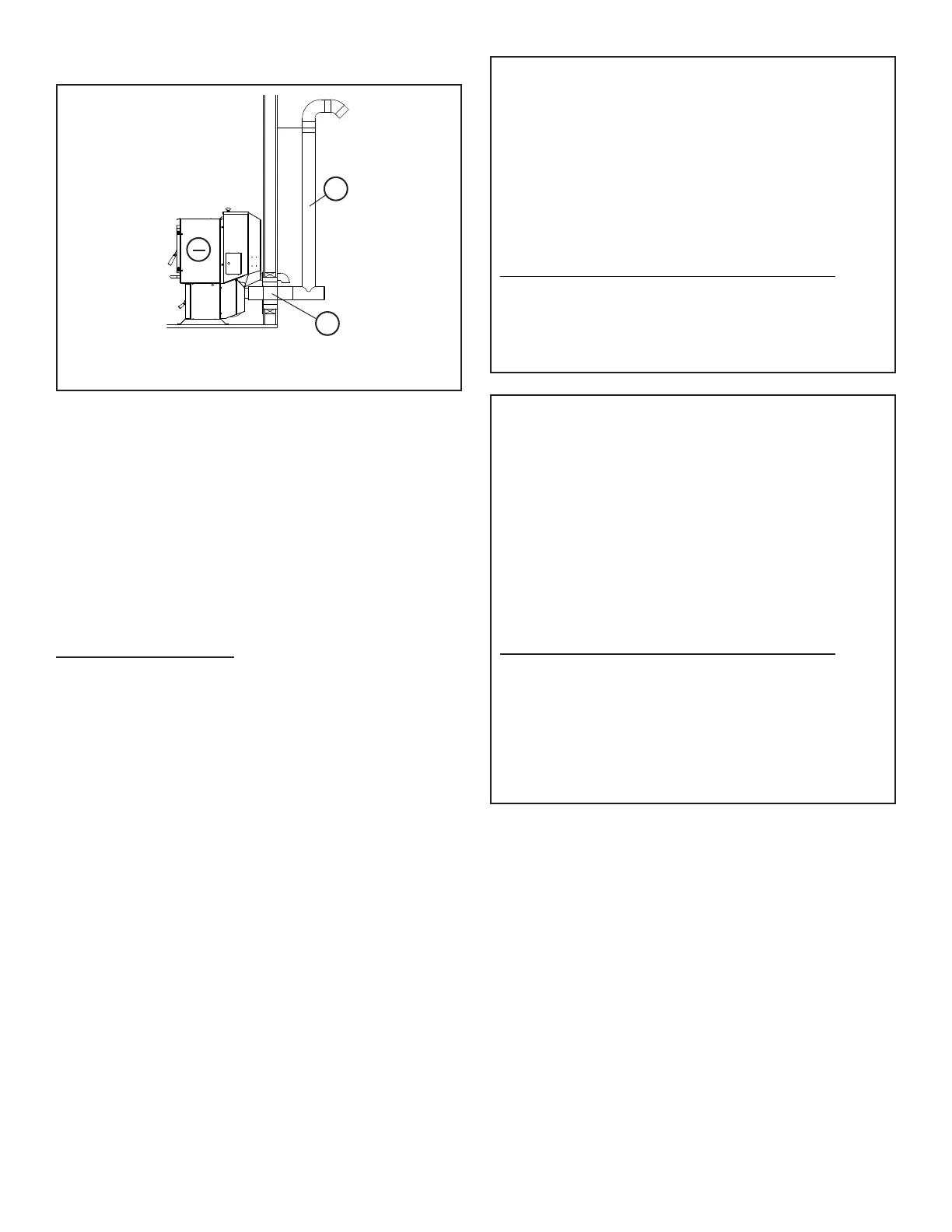

C. Venting & Use of Elbows

O

+

= Positive static pressure

= Negative static pressure

O

-

Figure 4.11

+

+

Example: First Floor Installation

A unit is to be installed using 3” Pellet Pipe with 3 feet

of horizontal pipe, a Tee, 10 feet of vertical pipe, a 90°

elbow and a termination cap.

The equivalent vent length is:

3 ft. of Horizontal Pipe (1 x 3 EVL) = 3 EVL

90° Elbow or Tee (1 x EVL) = 5 EVL

10 ft. of Vertical Pipe (10 x .5 EVL) = 5 EVL

90° Elbow or Tee (1 x EVL) = 5 EVL

Termination Cap = 0 EVL

Equivalent Vent Length = 18 EVL

In the example system detailed above, the EVL was 138

which is less than the maximum of 20 EVL for 3” pellet

ventpipe,thusthisisasatisfactoryventingconguration.

Example: Connection to Masonry Chimney

A unit is to be installed using 3” Pellet Pipe with 2 feet of

horizontal pipe, a Tee, 4 feet of vertical pipe, an elbow, a

Tee, 21 feet of vertical liner, and a termination cap.

The equivalent vent length is:

2 ft. of Horizontal Pipe (1 x 2 EVL) = 2 EVL

90° Tee (1 x 5 EVL) = 5 EVL

4 ft. of Vertical Pipe (4 x .5 EVL) = 2 EVL

90° Elbow (1 x 5 EVL) = 5 EVL

90° Tee (1 x 5 EVL) = 5 EVL

21 ft. of Vertical Liner (21 x .5 EVL) = 10.5 EVL

Termination Cap = 0 EVL

Equivalent Vent Length = 29.5 EVL

In the example system detailed above, the EVL was

29.5 which exceeds the maximum of 20 ft. for 3” pellet

vent pipe, thus 3” vent pipe should not be used in this

installation. However, since 4” pipe can support an EVL

up to 30, the use of 4” pipe would create a satisfactory

installation.

Loading...

Loading...