25 – English

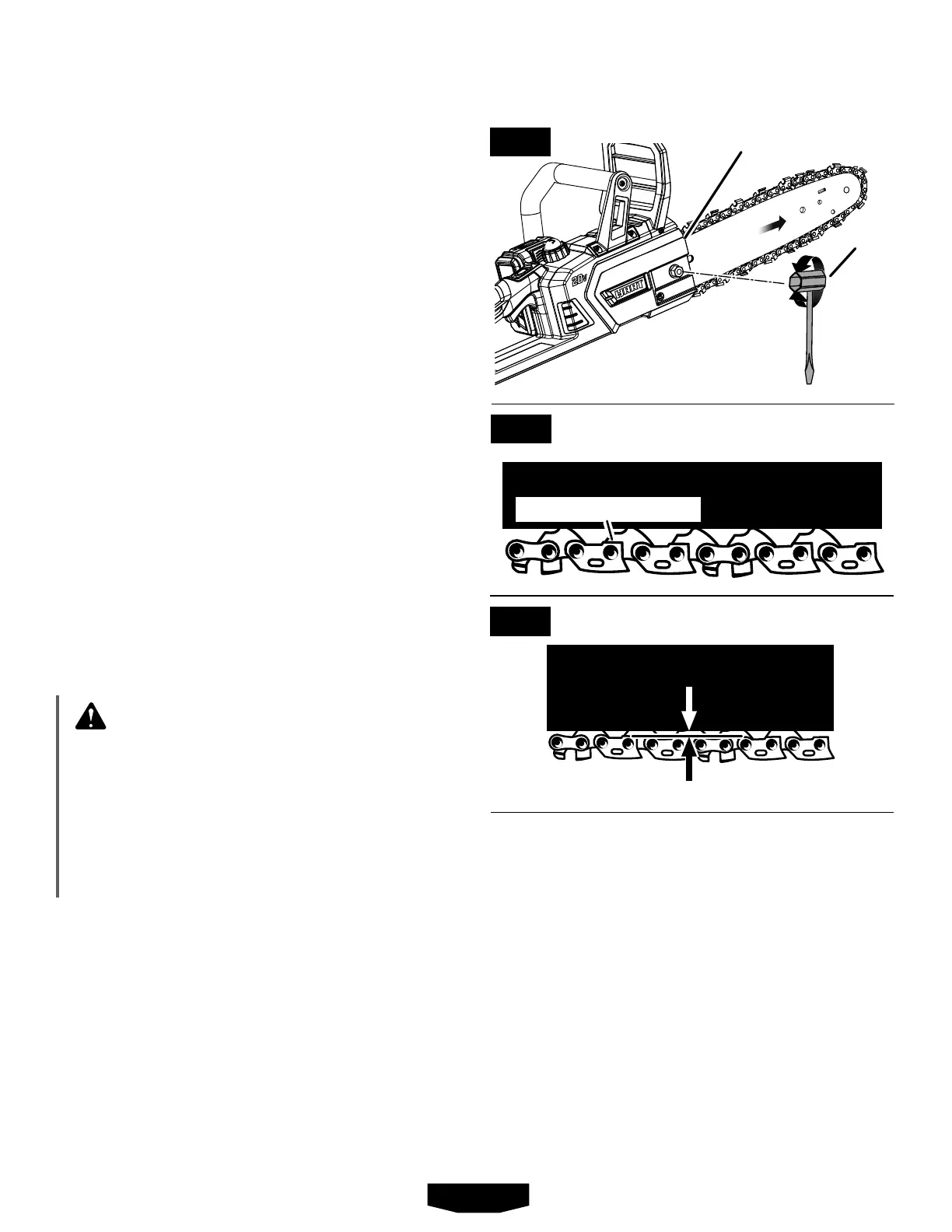

FLATS ON TIE STRAPS

Removealltheslackfromthechainbyturning

thechaintensioningscrewclockwiseuntilthe

chainseatssnuglyagainstthebarwiththedrive

linksinthebargroove.

Liftthe tip of the guidebarup to check for

sag.Releasethetipoftheguidebarandturn

thechaintensioningscrew1/2turnclockwise.

Repeatthisprocessuntilsagdoesnotexist.

Holdthetipoftheguidebarupandtightenthe

bar mounting screw securely.

Chainiscorrectlytensionedwhenthereisno

sagontheundersideoftheguidebar,thechain

issnug,butitcanbeturnedbyhandwithout

binding.

NOTE:Ifchainistootight,itwillnotrotate.

Loosenthechaincoverscrewslightlyandturn

tensionadjuster1/4turncounterclockwise.Lift

thetipoftheguidebarupandretightenchain

coverscrewsecurely.Assurethatthechainwill

rotatewithoutbinding.

Placethehexkeybackintothestoragearea.

ADJUSTING CHAIN TENSION

See Figures 29 - 30.

WARNING:

Shutoffthemotor,waitforallmovingpartsto

stop,andremovethebatterypack.Nevertouch

oradjustthechainwhiletheengineisrunning.

Thesawchainisverysharp.Alwayswear pro-

tectivegloveswhen performingmaintenance

on thechain. Failuretofollowtheseinstructions

canresultinseriouspersonalinjury.

Properchaintensioniscriticaltotheperformance

ofyour chain saw. Always check chain tension

beforeusingthe saw and periodically until the

workiscomplete.

Acoldchainiscorrectlytensionedwhenthereis

noslackontheundersideoftheguidebar.The

chainshouldbesnug,butstillabletobeturned

byhandwithoutbinding.

MAINTENANCE

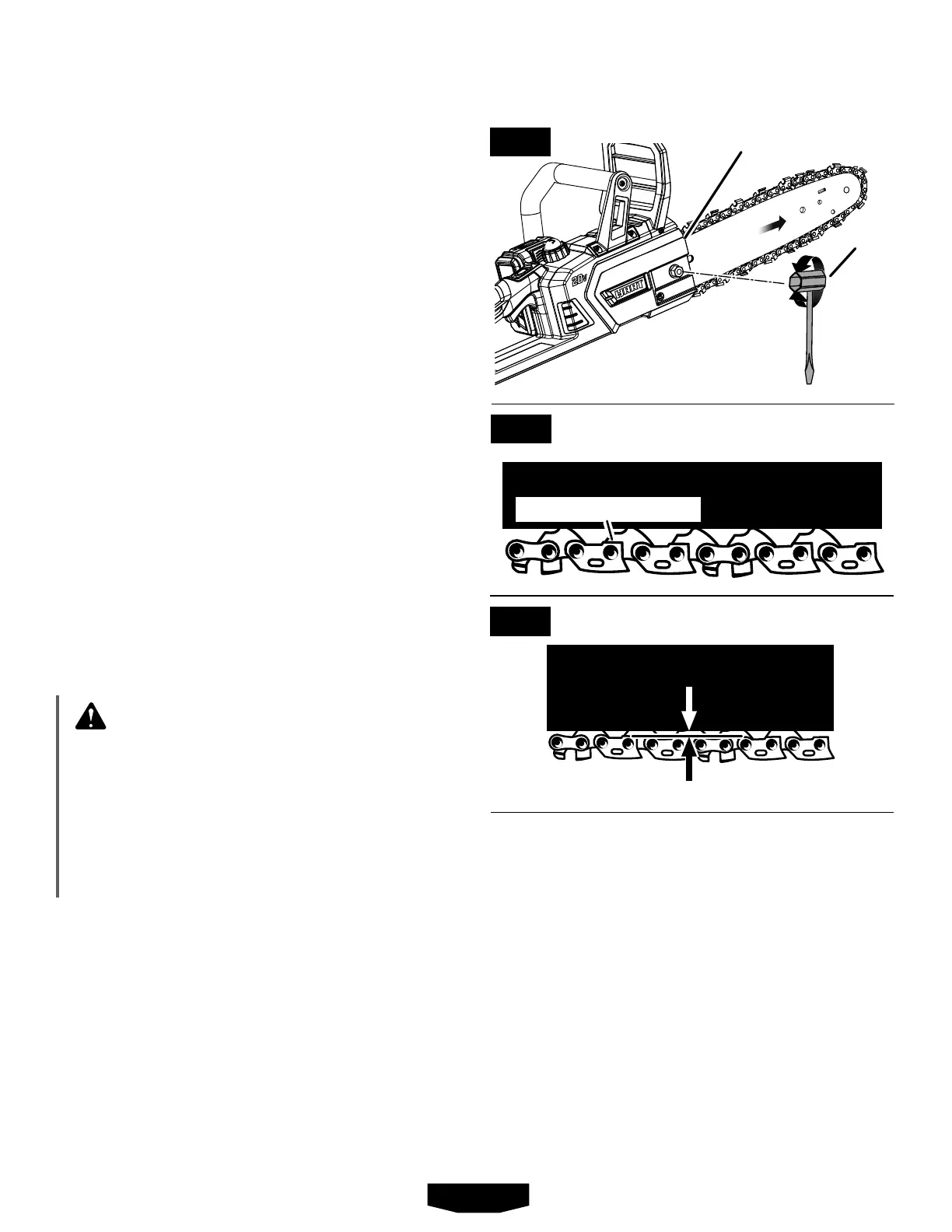

SCRENCH

APPROX. .050 in.

Awarmchainiscorrectlytensionedwhentheflats

onthetiestrapshangapproximately.050inches

outofthebargroove.

If adjustment is needed:

Loosenthechaincoverscrewtofingertight.

Raisethetipoftheguidebarandcontinueto

holdupuntiltheendofthisprocedure.

Turnthechaintensioningscrewclockwiseuntil

theflatsonthetiestrapsofthechaincontact

thebar,makingsurethedrivelinksareseated

insidethebargroove.

CHAIN COVER

SCREW

FIG. 28

FIG. 29

FIG. 30

Loading...

Loading...