26 – English

RESTORE ORIGINAL

SHAPE BY ROUNDING

THE FRONT

LUBRICATING HOLE

MAINTENANCE

FIG. 41

FIG. 42

INCORRECT TOP PLATE FILING

ANGLE

MORE

THAN 30°

LESS

THAN 30°

30°

CORRECT TOP PLATE

FILING ANGLE

INCORRECT SIDE PLATE

FILING ANGLE

BACKWARD

SLOPE

HOOK

80°

CORRECT SIDE

PLATE FILING

ANGLE

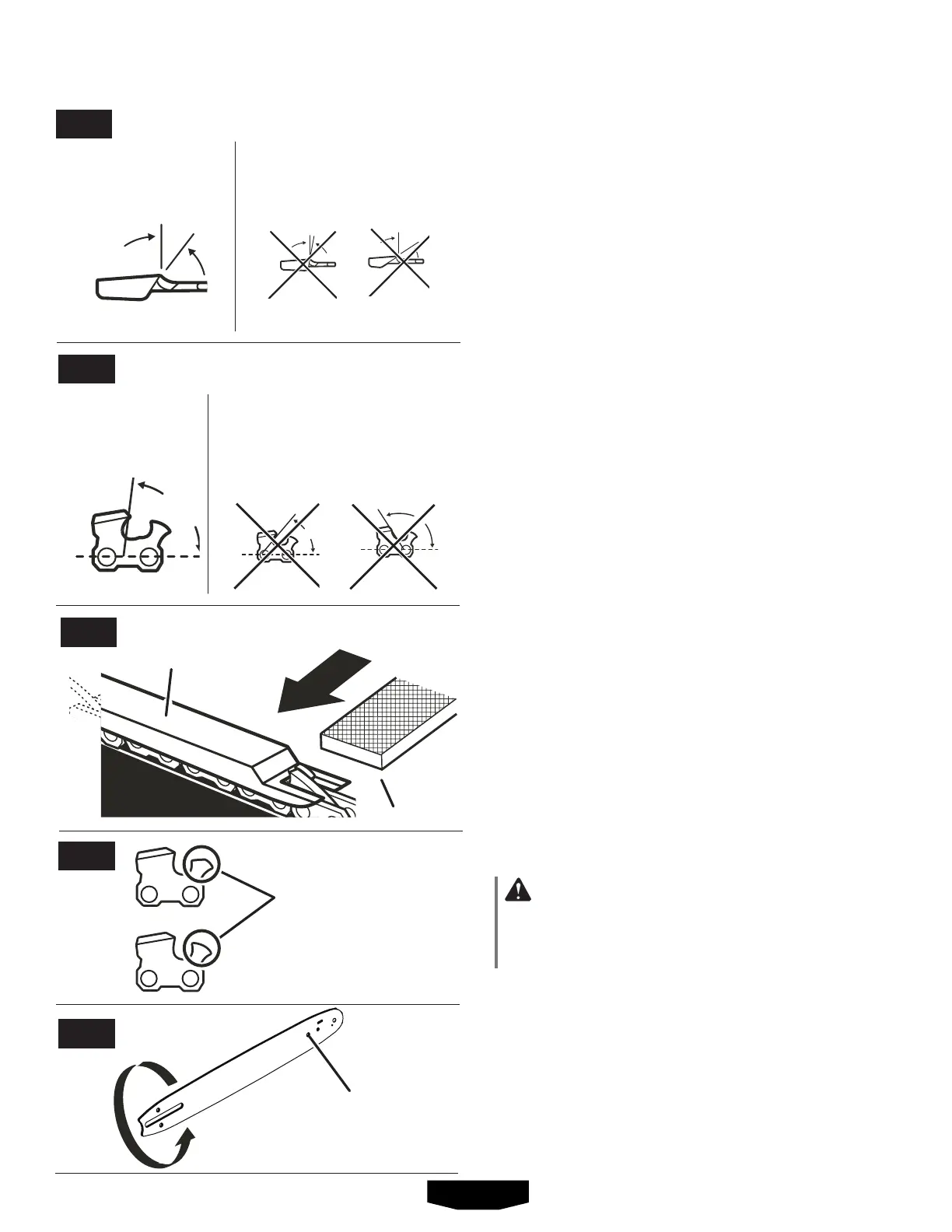

FIG. 38

FIG. 39

FLAT FILE

DEPTH GAUGE JOINTER

FIG. 40

SIDE PLATE ANGLE

See Figure 39.

CORRECT- 80°

Produced automatically if

correct diameter file is used in file holder.

HOOK-“Grabs”anddullsquickly.Increases

potentialofKICKBACK.

Results from using a file with diameter too small,

or file held too low.

BACKWARDSLOPE -Needstoo muchfeed

pressure, causesexcessive wear tobar and

chain.

Results from using a file with diameter too large,

or file held too high.

DEPTH GAUGE CLEARANCE

See Figures 40 - 41.

The depth gaugeshould bemaintained at a

clearanceof.025in.Useadepthgaugetool

forcheckingthedepthgaugeclearances.

Everytimethechainisfiled,checkthedepth

gauge clearance.

Useaflatfileandadepthgaugejointertolower

allgauges uniformly.Depth gaugejointers are

availablein.020in.to.035in.Usea.025in.depth

gaugejointer.Afterloweringeachdepthgauge,

restoreoriginalshapebyroundingthefront.Be

carefulnottodamageadjoiningdrivelinkswith

the edge of the file.

Depthgaugesmustbeadjustedwiththeflatfilein

the same direction the adjoining cutter was filed

with the round file. Use care not to contact cutter

facewithflatfilewhenadjustingdepthgauges.

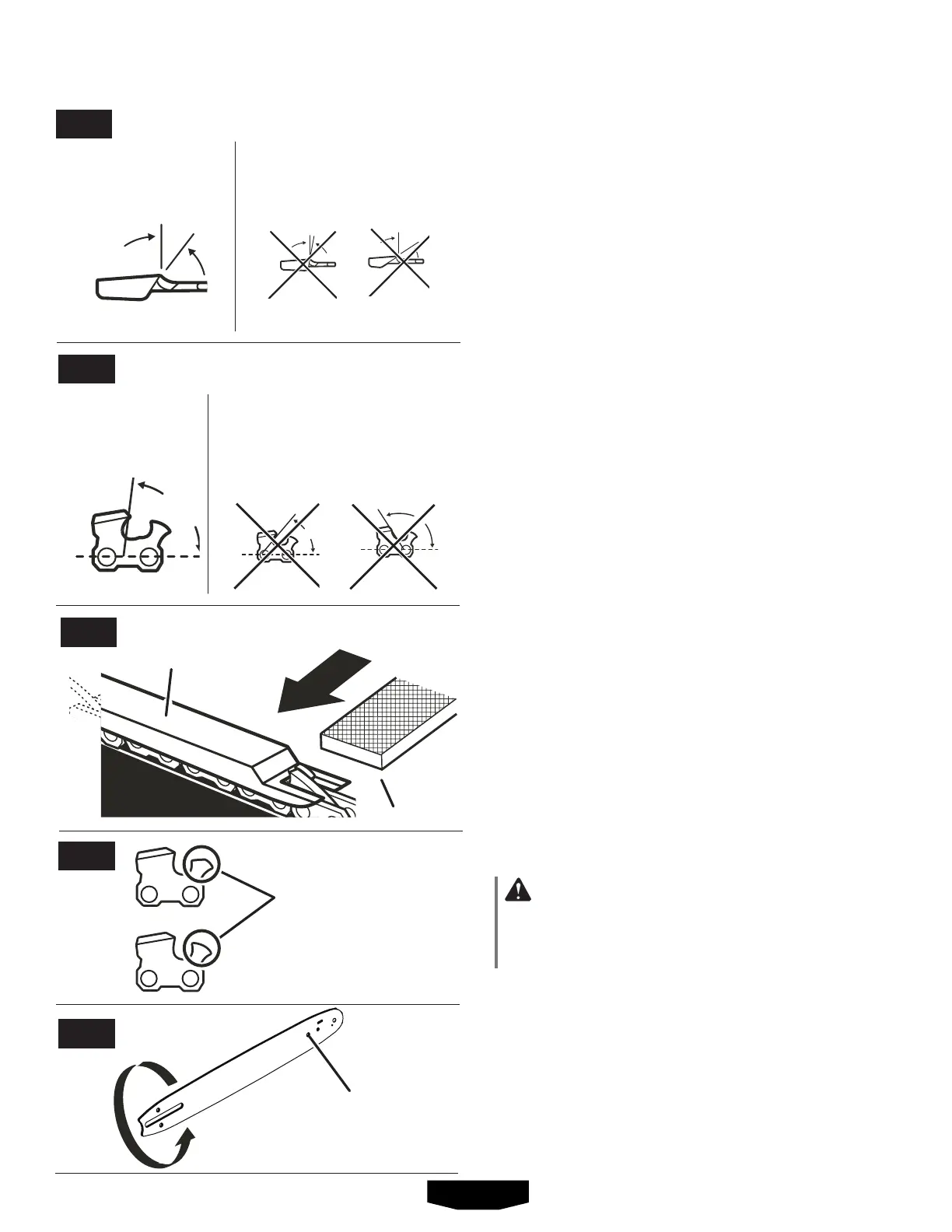

MAINTAINING THE GUIDE BAR

See Figure 42.

CAUTION:

Makesurethechainhasstoppedandthebat-

terypackhasbeenremovedbeforeyoudoany

workonthesawtoavoidpossibleinjury.

Propermaintenancewillmaximizetheusefullife

of the guide bar.

Each day of use:

Clean the bar and check for wear and damage.

Feathering or burring of the bar rails is a normal

processofbarwear,butsuchfaultsshouldbe

smoothed with a file as soon as they occur.

Loading...

Loading...