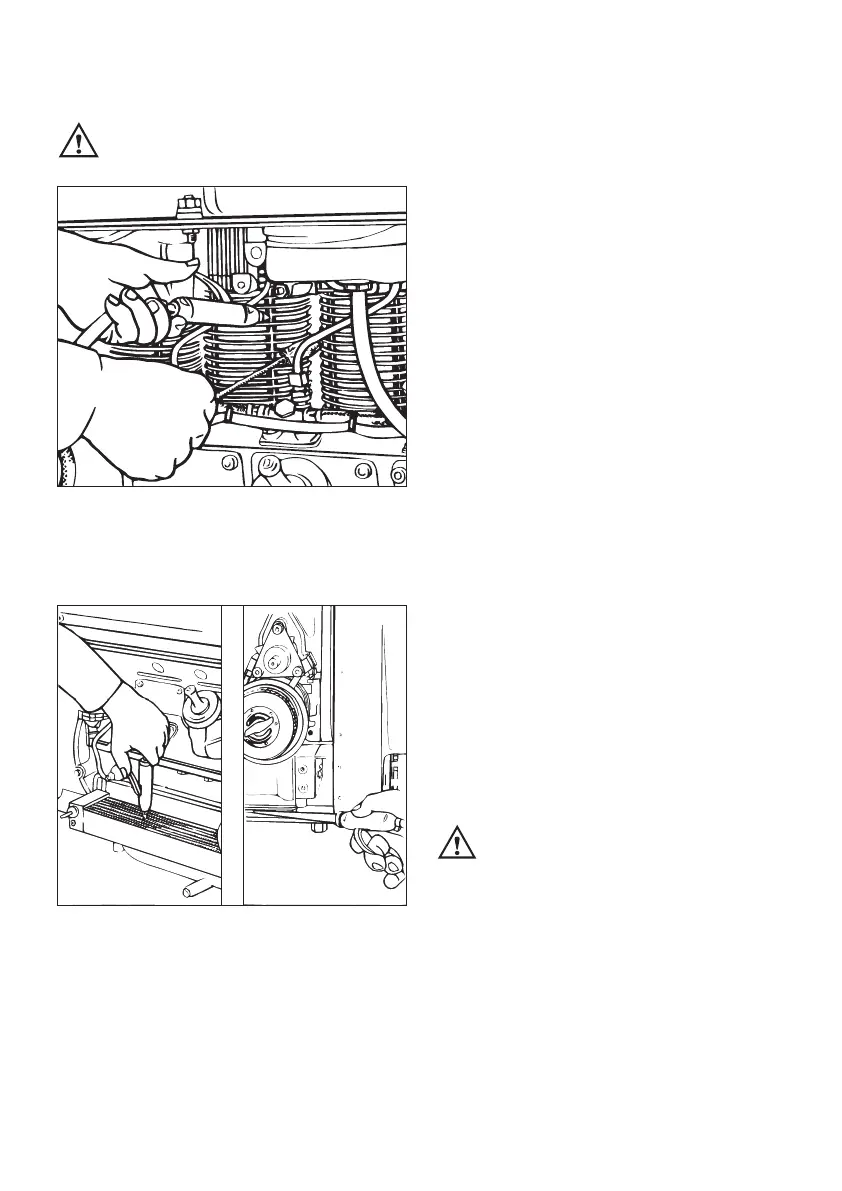

Removing dry dirt

Persons handling compressed air must

wear protective goggles.

38

– Clean the cooling fan, cylinder head and cylin-

ders with a suitable brush.

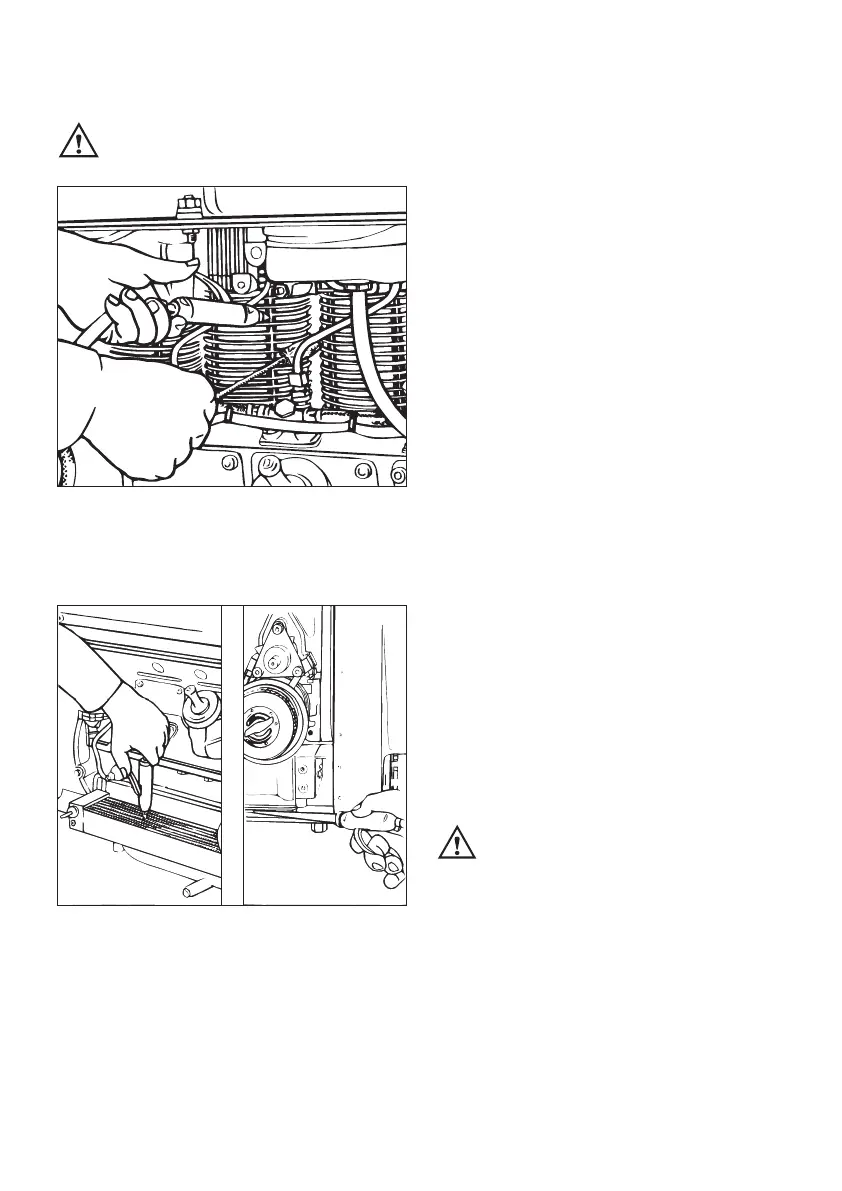

39

Note:

On the encapsulated engine, also clean the area

between the baseplate and the crankcase.

– Blow out the entire cooling area zone with

compressed air.

– Clean the engine oil cooler only by blowing out

with compressed air. In this case, do not direct

a powerful air jet against the easily damaged

cooling fins (Figure 39).

Removing damp or oily dirt

– Disconnect the negative lead at the battery.

– Manually clean alternator and regulator.

– Shield the alternator with attached voltage

regulator; do not spray it directly.

– Clean the complete area with a suitable deter-

gent solution in accordance with its manufac-

turer’s instructions, then spray down with a

powerful water jet.

Do not splash electrical system with water jet

or pressure jet during engine cleaning.

Note:

Do not use petrol (gasoline) or acid cleaning

agents.

– Dry the engine with a compressed air jet.

– Trace the cause of any contamination with oil

and have the leak eliminated by a HATZ service

station.

– Install the capsule or air guide elements

previously removed.

– Run the engine until warm, to prevent residual

moisture from causing rust.

The engine must never be run without

all guards and covers in position.

5.3.3. Checking threaded connections

Check the tightness of all threaded connections

and take up slack if necessary, provided that

these can be reached during maintenance work.

28

Loading...

Loading...