Note:

Do not tighten the cylinder head nuts.

The adjusting screws at the engine

governor and on the injection system

are sealed with lacquer or with lead and are

not to be tightened or adjusted.

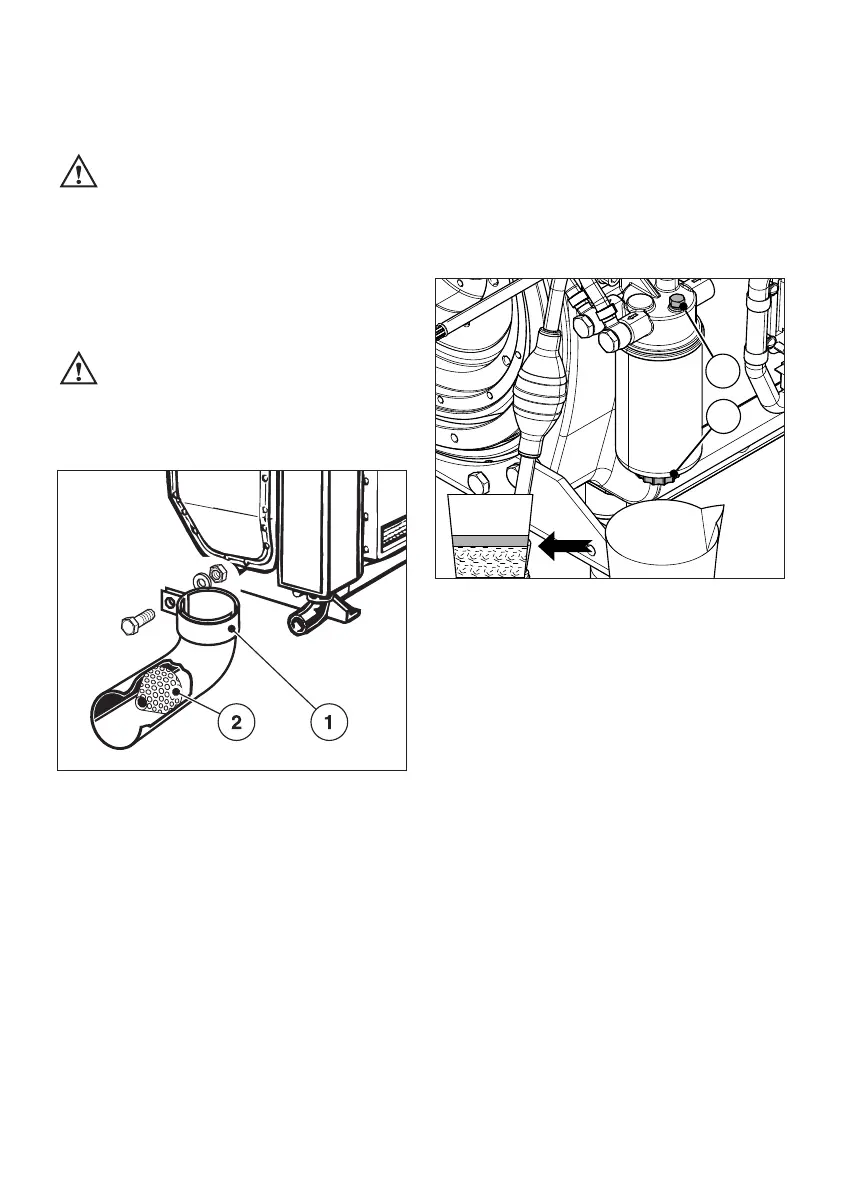

5.3.4. Cleaning of mesh insert in exhaust

pipe (additional equipment)

Exhaust system components will natu-

rally be hot and must not be touched

while the engine is running or until it has

cooled down after being stopped.

40

– Loosen pipe clip „1“ and remove with exhaust

pipe.

– Remove deposits in mesh insert „2“.

– Check mesh insert on chinks or fractures, re-

place if necessary.

Remark:

Engine operation for a longer period of time

without load or with less load can lead to de-

posits in the mesh insert. Shorten maintenance

interval.

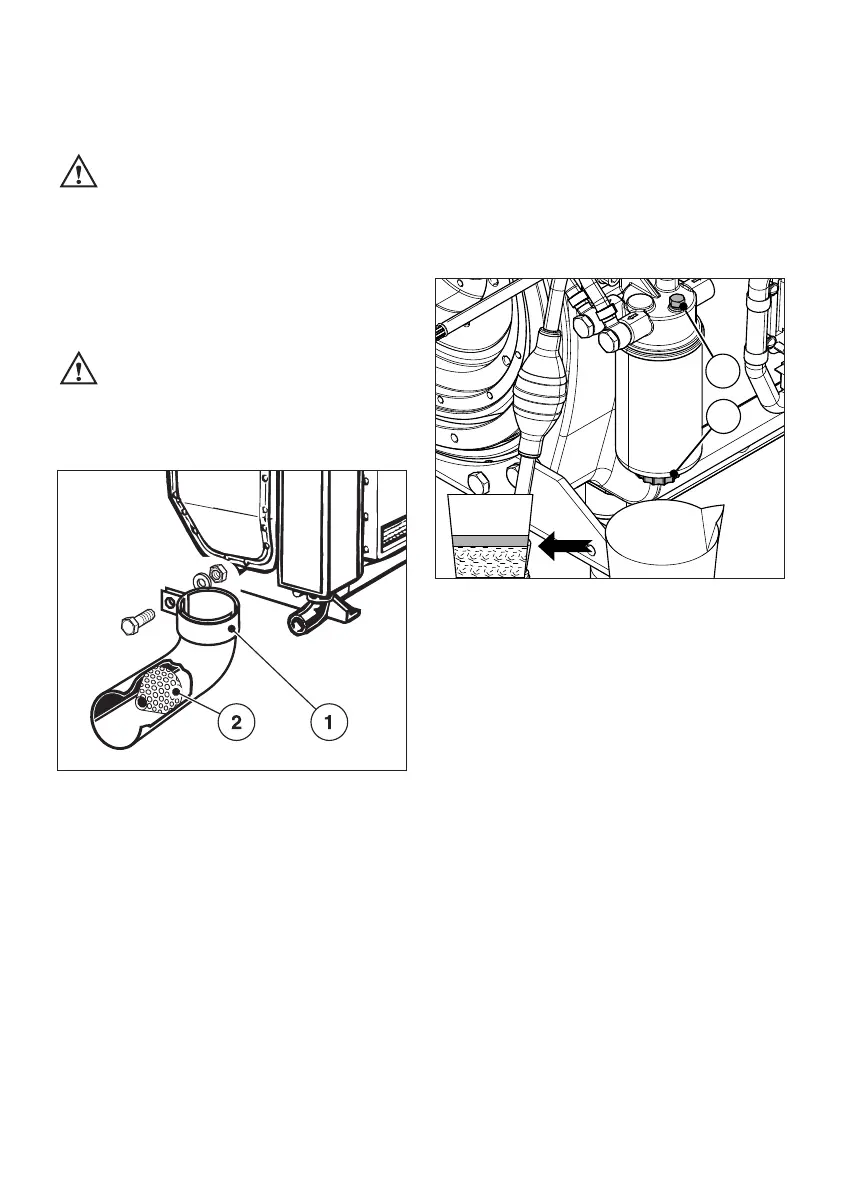

5.3.5. Check water trap

(

On 4L42C and 4M42 engines only)

The water trap inspection interval depends

exclusively on the water contained in the fuel

and on the care applied in refuelling. It may be

admissible to extend the intervals, or it may be

necessary to considerably shorten the intervals.

41

– Release the drain plug „1“ and collect the

liquid in a transparent vessel.

If the drain plug is not easily accessible, an

extension piece of hose can be slipped on the

plug.

– If an insufficient amount of liquid leaves the

tank, release additionally plug „2“.

As water is heavier than diesel fuel, first the

water, then the fuel will escape. This is indicated

by the clearly visible separating line.

– If finally only fuel leaves through the port, the

drain plug „1“ can be closed again.

– Subsequently, re-tighten plug „2“.

Note:

If starting appears difficult, bleed the injection

system using the manual fuel pump (Chapter

4.1.2.)

Loading...

Loading...