MAINTENANCE •••••••••••••••••••••••••••••••••••••••••

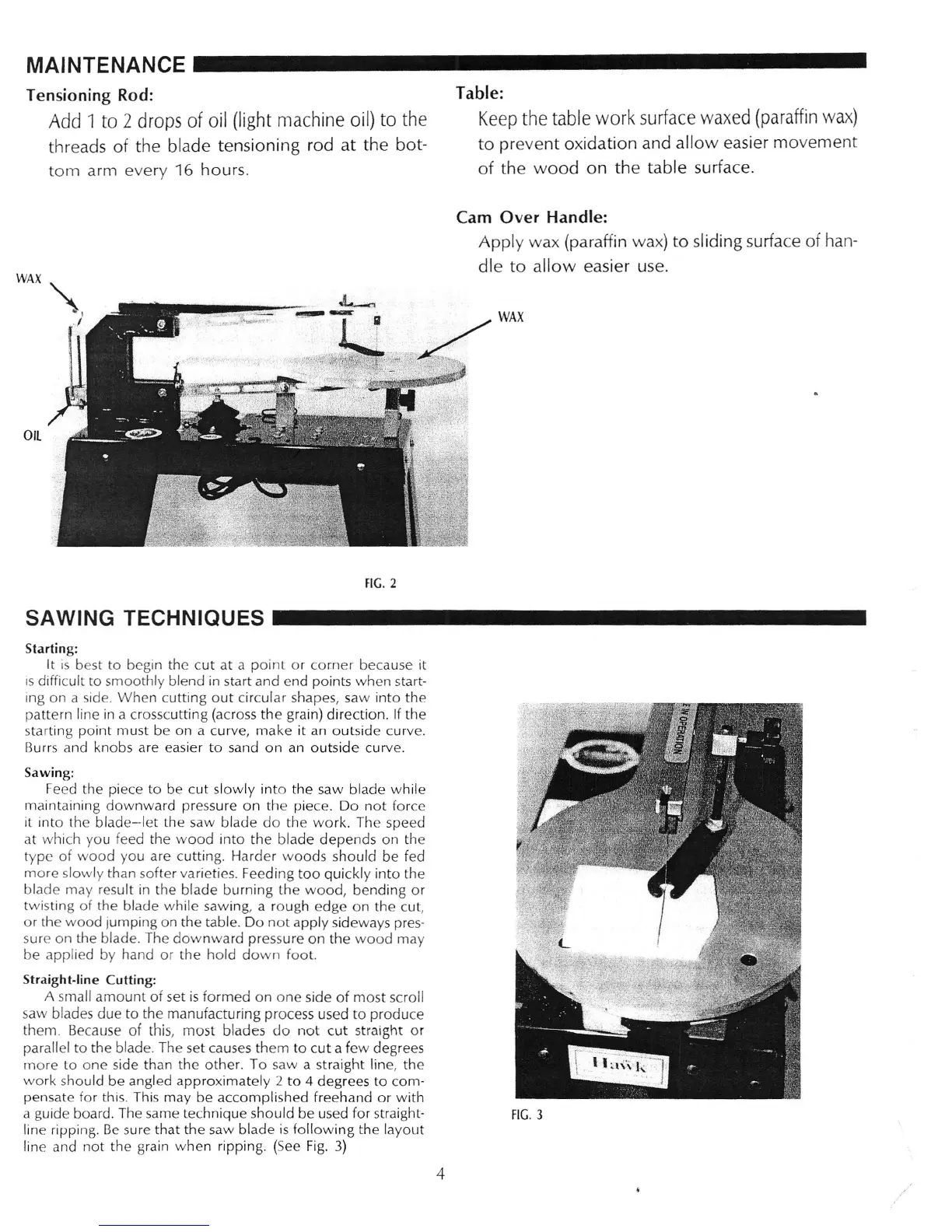

Tensioning Rod:

Add 1 to 2 drops of oil (light machine oil) to the

threads of the blade tensioning rod at the bot-

tom arm every

16

hours.

WAX

Ie •• " ~

.1{."I'o\}"!ntDo"' ••••..·

OIL

FIG.

2

Table:

Keep the table work surface waxed (paraffin wax)

to prevent oxidation and allow easier movement

of the wood on the table surface.

earn Over Handle:

Apply wax (paraffin wax) to sliding surface of han-

dle to allow easier use.

WAX

SAWING TECHNIQUES ••••••••••••••••••••••••••••••••••••

Starting:

It is best to begin the cut at a point or corner because it

is difficult to smoothly blend in start and end points when start-

ing on a side. When cutting out circular shapes, saw into the

pattern line in a crosscutting (across the grain) direction. If the

starting point must be on a curve, make it an outside curve.

Burrs and knobs are easier to sand on an outside curve.

Sawing:

Feed the piece to be cut slowly into the saw blade while

maintaining downward pressure on the piece. Do not force

it into the blade-let the saw blade do the work. The speed

at which you feed the wood into the blade depends on the

type of wood you are cutting. Harder woods should be fed

more slowly than softer varieties. Feeding too quickly into the

blade may result in the blade burning the wood, bending or

twisting of the blade while sawing, a rough edge on the cut,

or the wood jumping on the table. Do not apply sideways pres-

sure on the blade. The downward pressure on the wood may

be applied by hand or the hold down foot.

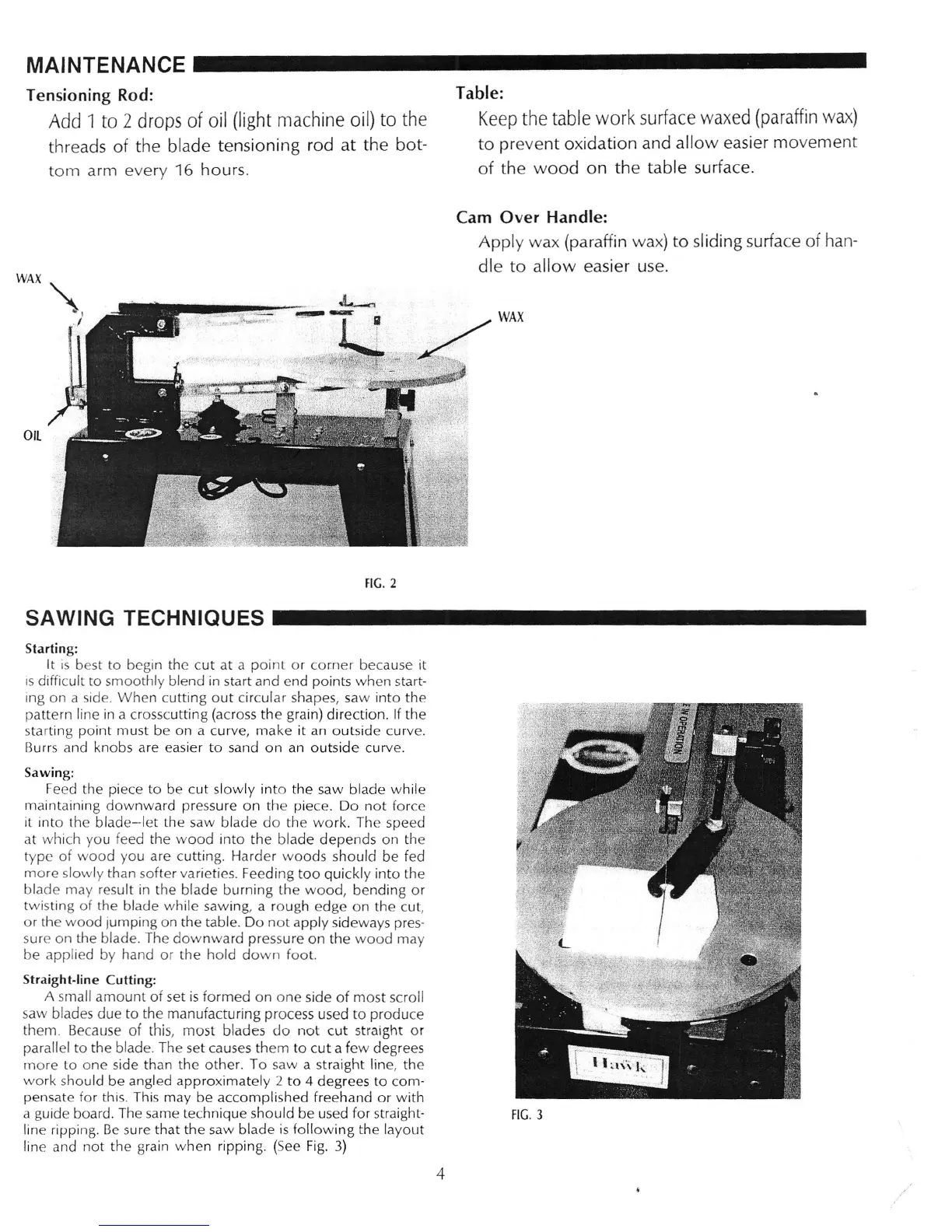

Straight-line Cutting:

A

small amount of set is formed on one side of most scroll

saw blades due to the manufacturing process used to produce

them Because

of this,

most blades do not cut straight or

parallel to the blade. The set causes them to cut a few degrees

more to one side than the other. To saw a straight line, the

work should be angled approximately

2

to

4

degrees to com-

pensate for this. This may be accomplished freehand or with

a guide board. The same technique should be used for straight-

line ripping. Be sure that the saw blade is following the layout

line and not the grain when ripping. (See Fig. 3)

4

FIG.3

Loading...

Loading...