Compound Sawing:

The compound sawing process involves cutting on

two or more sides of the work piece. To do this, sim-

ply layout a pattern on two adjoining surfaces. These

patterns may be identical or different. After the pat-

terns are laid out, choose which surface to saw first.

It usually will not make any difference which surface

you choose, but consider the sequence before

choosing. The side that will give the least amount

of scrap pieces after it is cut should be first. After

the first side is cut, return the scrap pieces to their

original locations so that you have a prismatic shape

to cutout the second surface. It may be helpful to

nail, tape, or glue these scraps back on the piece.

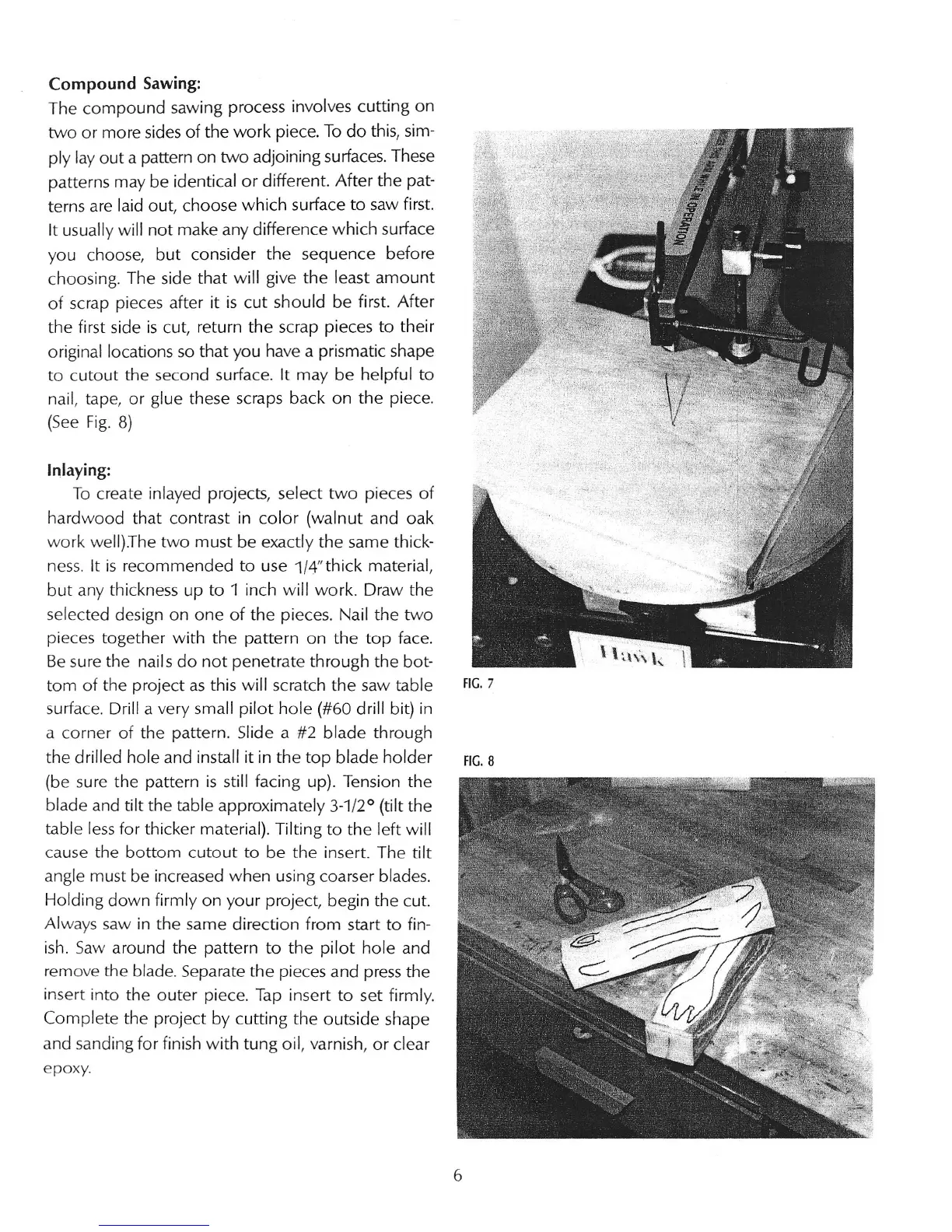

(See Fig. 8)

Inlaying:

To create inlayed projects, select two pieces of

hardwood that contrast in color (walnut and oak

work well).The two must be exactly the same thick-

ness. It is recommended to use 1/4" thick material,

but any thickness up to

1

inch will work. Draw the

selected design on one of the pieces. Nail the two

pieces together with the pattern on the top face.

Be sure the nail s do not penetrate through the bot-

tom of the project as this will scratch the saw table

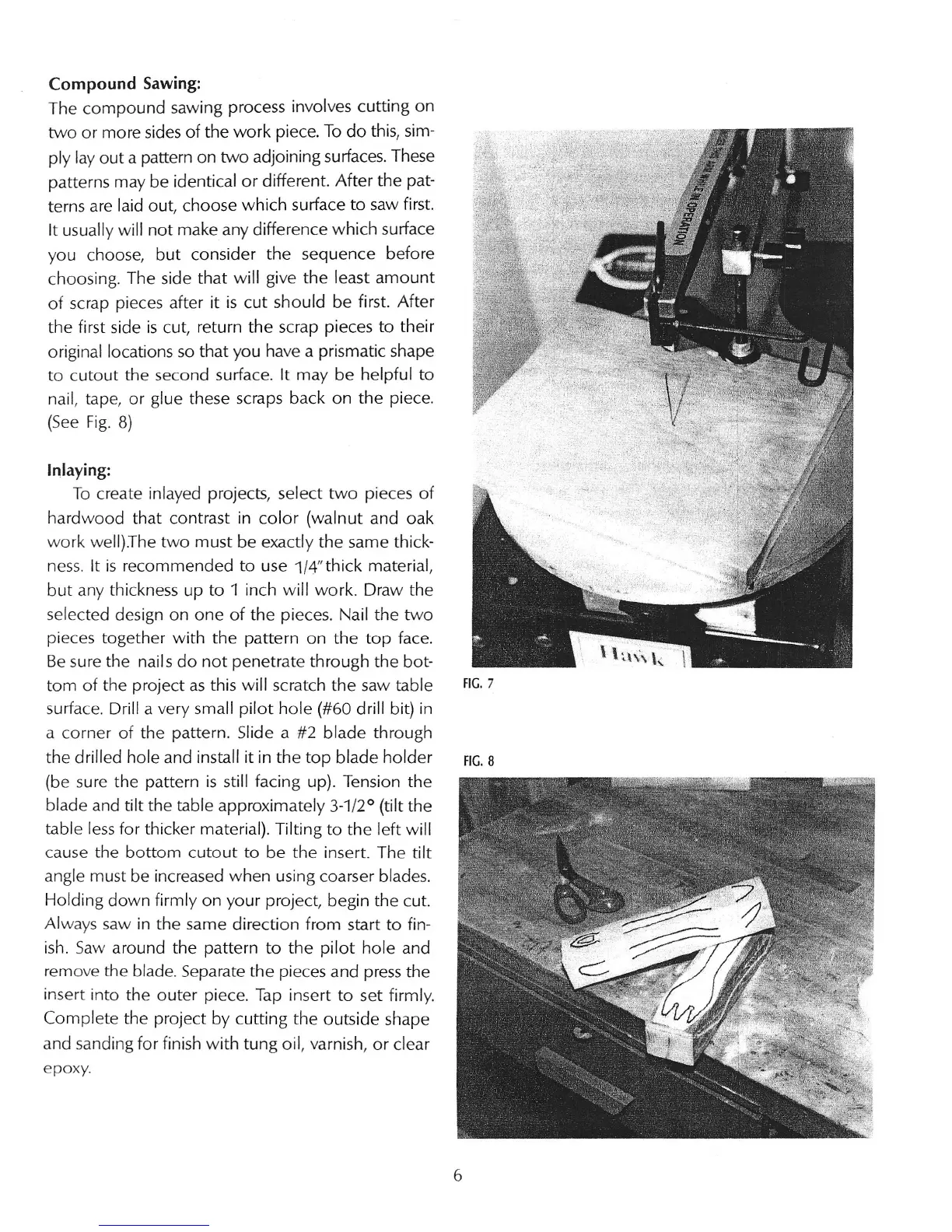

FIG. 7

surface. Drill a very small pilot hole (#60 drill bit) in

a corner of the pattern. Slide a #2 blade through

the drilled hole and install it in the top blade holder

FIG. 8

(be sure the pattern is still facing up). Tension the

blade and tilt the table approximately 3-1/2° (tilt the

table less for thicker material). Tilting to the left will

cause the bottom cutout to be the insert. The tilt

angle must be increased when using coarser blades.

Holding down firmly on your project, begin the cut.

Always saw in the same direction from start to fin-

ish. Saw around the pattern to the pilot hole and

remove the blade. Separate the pieces and press the

insert into the outer piece. Tap insert to set firmly.

Complete the project by cutting the outside shape

and sanding for finish with tung oil, varnish, or clear

epoxy.

6

Loading...

Loading...