44

Task 10.9 - Commissioning of repaired batteries

OPERATING INSTRUCTION AND TECHNICAL REQUIREMENTS (TR) INSTRUCTIONS / EVIDENCE WHEN DEVIATIONS FROM TR

1. Measure the insulation resistance in accordance with Task 8.3

Requirement: R>0.5 MΩ.

Carry out battery cleaning, Task 8.6.

2. Remove the lid from the battery.

3. Connect the battery to the charge / discharge unit.

4. Undo the vents from the cells and keep them aside on cell’s mouth.

5. Charge the battery for 8 hours at 0.2*I

1

.

6. Allow the battery to stand for 1 hour.

7. Discharge the 24V battery at I

1

to 20V.

Requirement: The voltage of each cell after 48 minutes must be equal

/ greater than 1 Volt.

Note: If the discharge at the I

1

rate is not feasible, select a different

discharge rate and criteria from the table below:

Requirement: Cell voltage shall be ≥ 1.0V at the defined discharge

time in column two.

Replace all cells, if more than 6 cells from the original 24V

battery have failed the discharge requirement.

8. Allow the battery to soak to room temperature, which can take up

to 8 hours.

9. Charge the battery either for 7 hours at 0.2*I

1

(Appendix 2) or apply

the IUI-method (Appendix 1) adjust the electrolyte level prior to the

end of charge and measure the end of charge voltages of the cells.

Requirement: >1.56 V

Replace all cells, if more than 6 cells from the original 24V

battery have failed the charge requirement.

10. Record the results in the log book.

11. Tighten the vents between 1 hour and 24 hours after charge.

12. Refit the lid on the battery.

13. Measure the insulation resistance in accordance with Task 8.3

Requirement: R>0.5 MΩ.

Carry out battery cleaning, Task 8.6.

14. Release the battery to service, if necessary, in accordance

with Task 3.3.

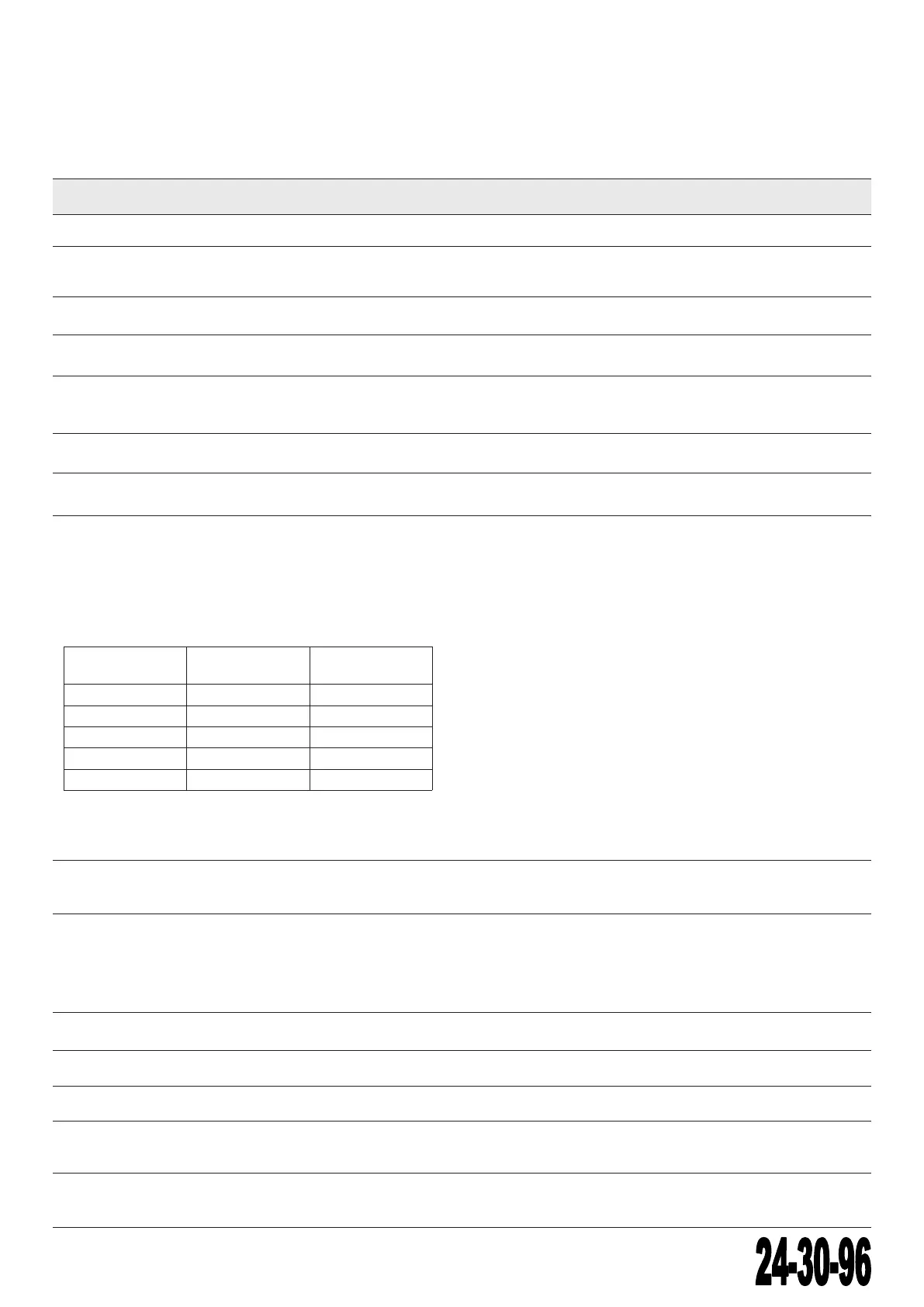

Discharge current rate Time (min) cell voltage

reading

Voltage requirement

for cells (V)

0.2*I

1

240 ≥1.0

0.4*I

1

120 ≥1.0

0.6*I

1

80 ≥1.0

0.8*I

1

60 ≥1.0

I

1

48 ≥1.0

The document reference is online, please check the correspondence between the online documentation and the printed version.

Loading...

Loading...