Magic 600 N000924 12/2010 9 / 208

must be supervised by a person who assumes

responsibility for their safety.

Installation must be performed by qualified service

technician.

Work on the electrical installation must only be carried out by

authorised specialist personnel.

The load capacity and suitability of the supporting

construction of the building in which the door operator is to be

installed must be inspected and approved by an expert.

The door operator must be fully and securely attached at all

fastening points. All fastening materials must be selected

according to the nature of the supporting construction and

they must be able to withstand traction force of 900 N.

In the event of non-conformance with these

requirements, there is a risk of injury and material

damage caused by a falling operator or an uncontrolled

movement of the door.

When drilling the fastening holes, do not damage the building

structure or any electrical, water or other lines.

After lifting up the door operator to the ceiling, fasten it fully

with appropriate tools to prevent it from falling down. See

illustration on page 159.

Please observe appropriate industrial safety regulations and

keep children away during installation.

The door operator has the following safety devices. Do

not remove them or alter their functionality.

• Automatic load switch-off during functions "OPEN" and

"CLOSE"

• Connection for photo cell / safety rail / optosensor

• EMERGENCY stop connection: Connection of a switch

(optional) to an inset door mounted in the garage door, for

example

• Emergency release (see page 161 (J))

Checking load switch-off

The automatic load switch-off is a clamping and safety

mechanism that is designed to prevent accidents due to a

moving door.

Stop the door from outside with both hands at waist height.

When closing:

The door must stop automatically and reverse a little if it

comes into contact with an obstruction.

When opening:

The door must stop automatically when it meets with

resistance (if menu A7 = 1, it moves back a short distance).

After load switch-off, the door operator lights flash until the

next pulse or wireless command is received.

Emergency release

Check as per the information provided on page 161 (J).

Additional safety devices

Check for proper functioning as per the manufacturer’s

instructions.

Messages of the indicator lamp (8)

Please note: Check that the door is working properly

and running smoothly, and adjust if necessary. The

spring tension of the door must be set in such a way that it is

stable and can be opened and closed by hand smoothly and

without jolting.

• Standard and appropriate shock-proof socket approx. 10 -

50 cm away from the fastening position for the head of the

operator.

(For information on fuses, see the technical data.)

• Only install the door operator in dry garages.

Make sure the installation set for the connection is ready on

7 Installation precautions

8 Safety devices of the door operator

9 Safety inspection

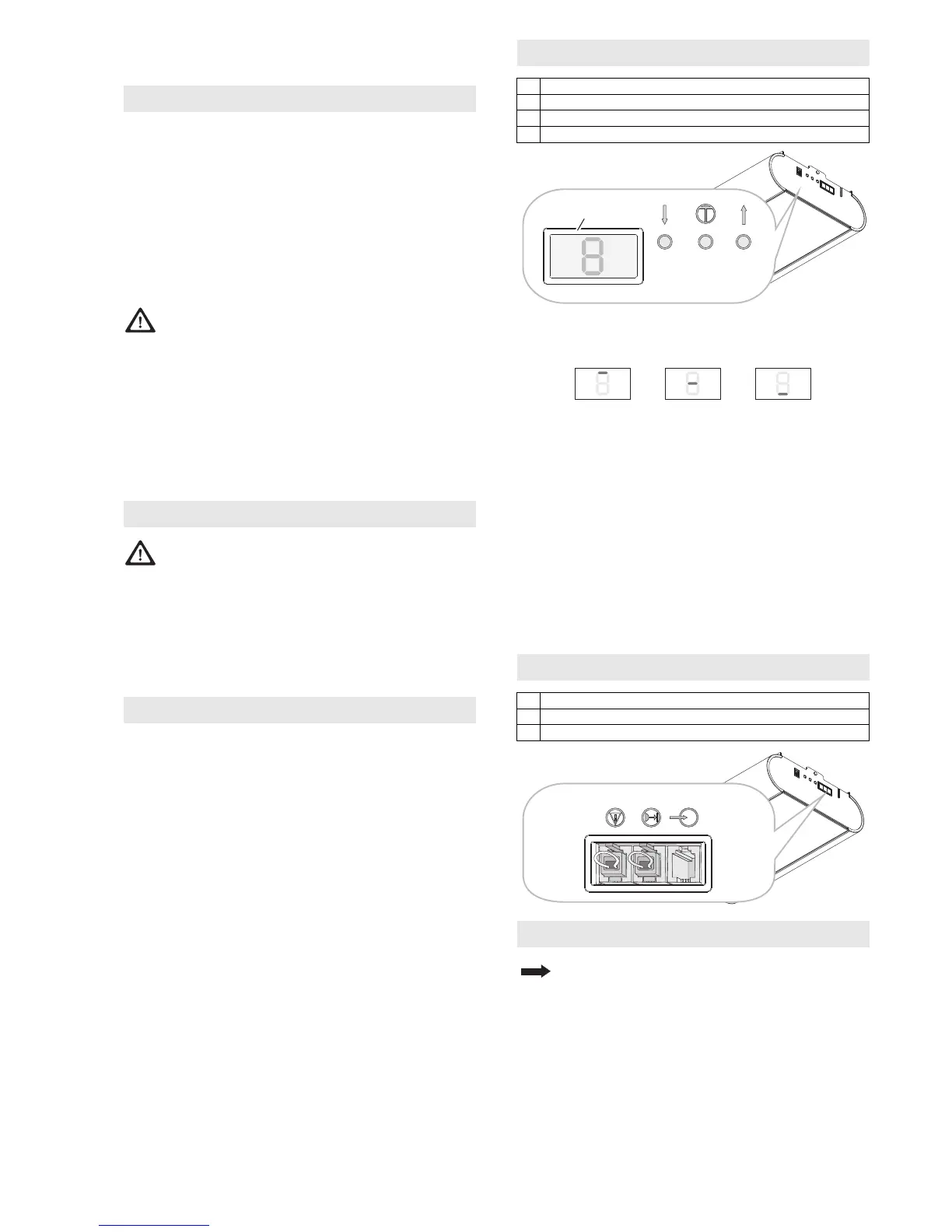

10 Controls and indicators

5 Pushbutton Close door / Minus

6 Pushbutton Menu / Confirm (Teach-in run)

7 Pushbutton Open door / Plus

8 Indicator lamp

Status messages

A door in end position OPEN

B door between the two end positions

C door in end position CLOSED

Status messages

During door movement in OPEN direction

C => B => A...

During door movement in CLOSE direction

A => B => C...

L4 Set end position OPEN

L3 Reference run CLOSE and set end position CLOSED

L2 Teach-in run OPEN (load values)

L1 Teach-in run CLOSE (load values)

Err Error and error number (flashing)

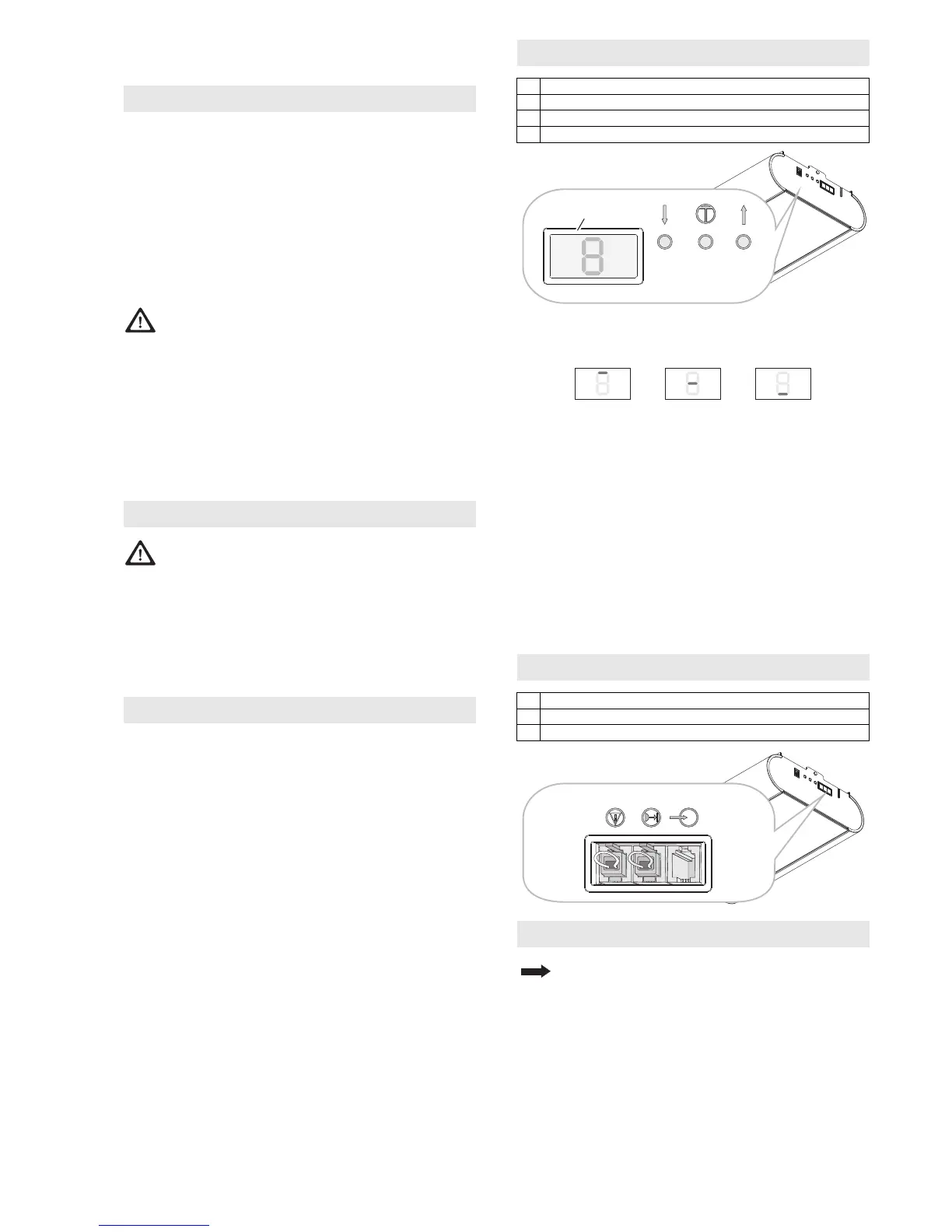

11 Connections

1 EMERGENCY stop (green)

2 Photo cell (yellow)

3Pulse

12 Installation preparations

Loading...

Loading...