PRIMAAX

®

EX / PRIMAAX

®

for Volvo Vehicles

Preventive Maintenance 20 17730-254

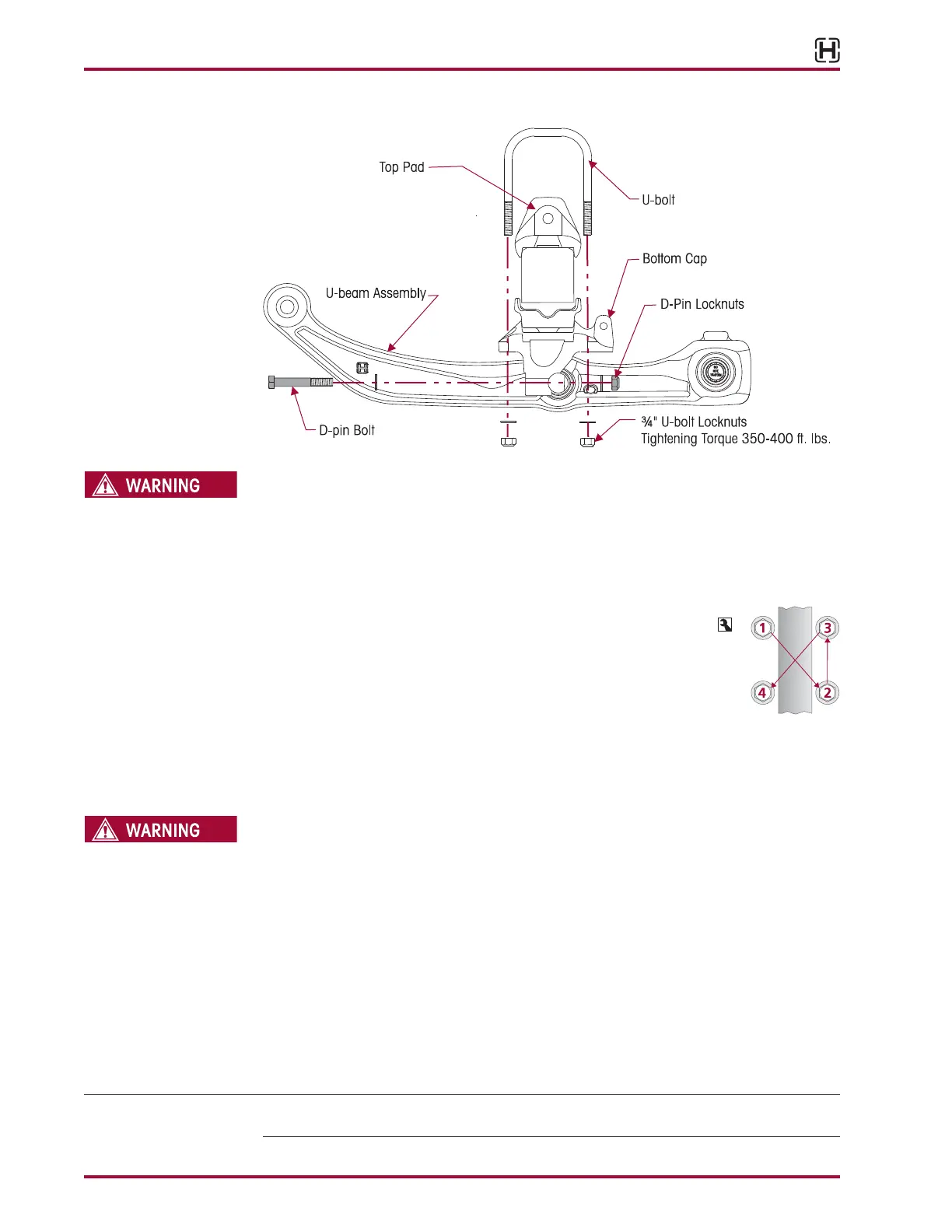

FIGURE 6-5

IT IS IMPORTANT THAT THE U-BOLT CLAMP GROUP CONNECTION BE PROPERLY ALIGNED AND

HAVE THE PROPER TORQUE VALUES MAINTAINED. METAL SURFACES CAN WORK AND WEAR

AGAINST OTHER RELATED CLAMP GROUP COMPONENTS IF NOT PROPERLY ALIGNED OR PROPERLY

TIGHTENED TO MAINTAIN THE PROPER CLAMP FORCE. FAILURE TO DO SO CAN CAUSE PREMATURE

COMPONENT WEAR, POSSIBLE SEPARATION OF THE CLAMP GROUP, CAUSING LOSS OF VEHICLE

CONTROL, PROPERTY DAMAGE, OR PERSONAL INJURY.

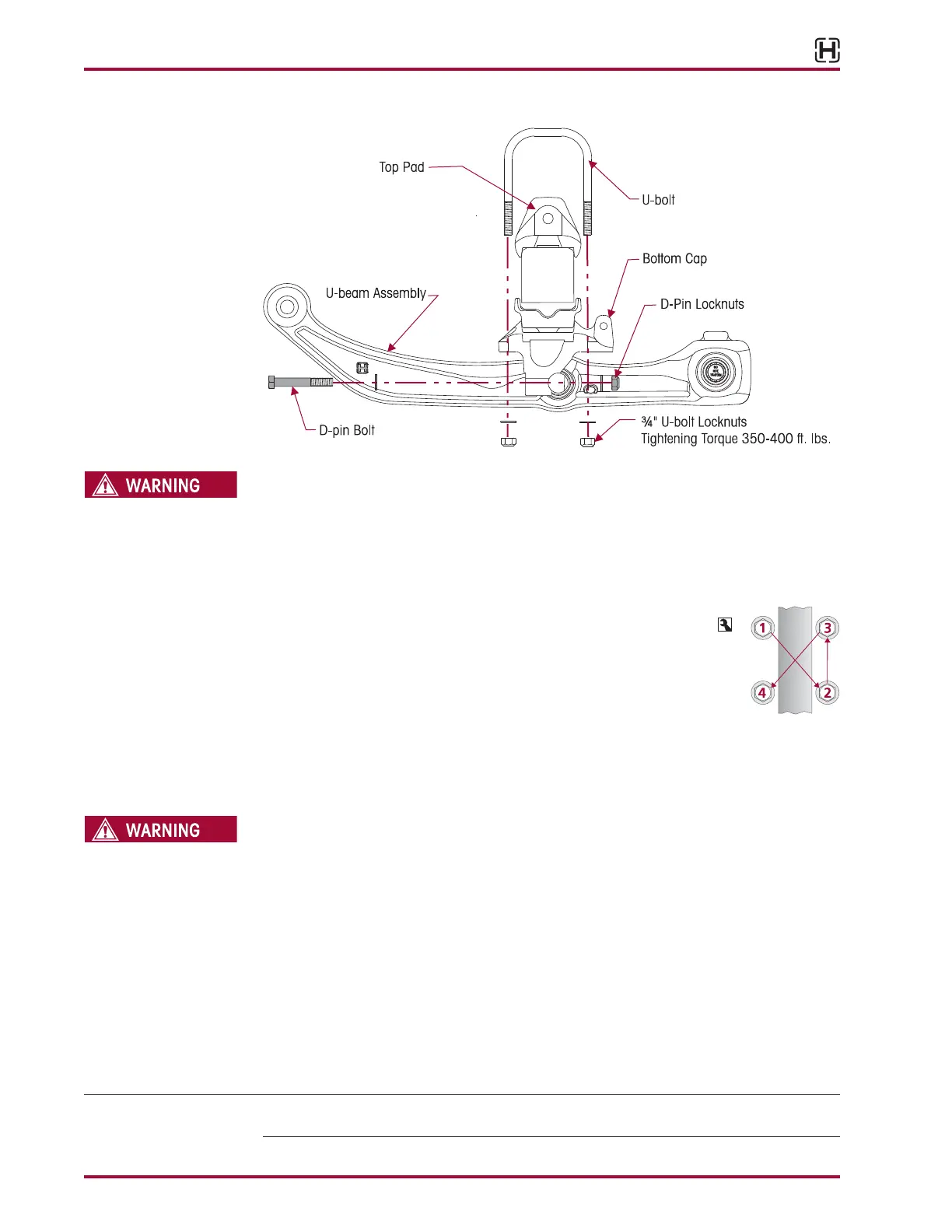

FIGURE 6-6

4. Tighten the U-bolt locknuts evenly in 50 foot pounds increments to

350-400 foot pounds torque in the proper pattern to achieve uniform bolt

tension, see Figure 6-6.

TRANSVERSE TORQUE RODS

The transverse torque rod is not supplied by Hendrickson, although it is a required component.

Hendrickson is not responsible for components supplied by the vehicle manufacturer. For assis-

tance with inspection, maintenance and rebuild instructions on these components see vehicle

manufacturer.

PRIMAAX EX / PRIMAAX SUSPENSIONS INCORPORATE TRANSVERSE RODS FOR VEHICLE STABILITY. IF

THESE COMPONENTS ARE DISCONNECTED OR ARE NON-FUNCTIONAL, THE VEHICLE SHOULD NOT

BE OPERATED. FAILURE TO DO SO CAN RESULT IN ADVERSE VEHICLE HANDLING, LOSS OF VEHICLE

CONTROL, POSSIBLE TIRE CONTACT WITH THE FRAME, PREMATURE COMPONENT DAMAGE, OR

SEVERE PERSONAL INJURY.

LONGITUDINAL TORQUE RODS

Torque rod looseness inspection is necessary during preventive maintenance and service inter-

vals per one of the following methods below. Inspect attaching fasteners for proper torque.

■

Method 1 — For tractor applications only with brakes applied, slowly rock the empty vehicle

with power while a mechanic visually checks the action at both ends.

■

Method 2 — with the vehicle shut down, a lever check can be made with a long pry bar

placed under each rod end and pressure applied.

NOTE Hendrickson recommends the use of Grade 8 bolts and Grade C locknuts for all straddle mount

torque rod attachments.

Loading...

Loading...