PRIMAAX

®

EX / PRIMAAX

®

for Volvo Vehicles

17730-254 47 Component Replacement

BOTTOM CAP AND AXLE SPACER

NOTE It is not necessary to loosen the QUIK-ALIGN connection to service the bottom cap and axle

spacer, therefore alignment is preserved during service. If the QUIK-ALIGN connection is

loosened during service, alignment is required after service is completed.

DISASSEMBLY

1. Chock the wheels of the axle.

2. Raise the frame of the vehicle to remove the load from the suspension. Support the frame.

3. Raise and support the axle being serviced. Remove the wheels.

4. Disconnect the height control valve linkage assembly from the height control valve arm(s)

from the rubber grommet (see vehicle manufacturers instructions).

PRIOR TO AND DURING DEFLATION AND INFLATION OF THE AIR SUSPENSION SYSTEM, ENSURE THAT

ALL PERSONNEL AND EQUIPMENT ARE CLEAR FROM UNDER THE VEHICLE AND AROUND THE SERVICE

AREA, FAILURE TO DO SO CAN CAUSE SERIOUS PERSONAL INJURY, DEATH, OR PROPERTY DAMAGE.

5. See additional Air Spring Cautions and Warnings in the Important Safety Notice Section of

this publication prior to deflating or inflating the air system.

SOME VEHICLE APPLICATIONS, SUCH AS VEHICLES EQUIPPED WITH OUTRIGGERS, RETAIN SOME

PRESSURE IN THE AIR SPRINGS AT ALL TIMES. PRIOR TO PERFORMING ANY MAINTENANCE, SERVICE,

OR REPAIR OF THE SUSPENSION, VERIFY EACH AIR SPRING IS COMPLETELY DEFLATED. FAILURE TO

DO SO COULD RESULT IN SERIOUS PROPERTY DAMAGE AND/OR SEVERE PERSONAL INJURY.

6. Lower the leveling valve arm(s) to exhaust the air in the air springs and deflate the rear

suspension.

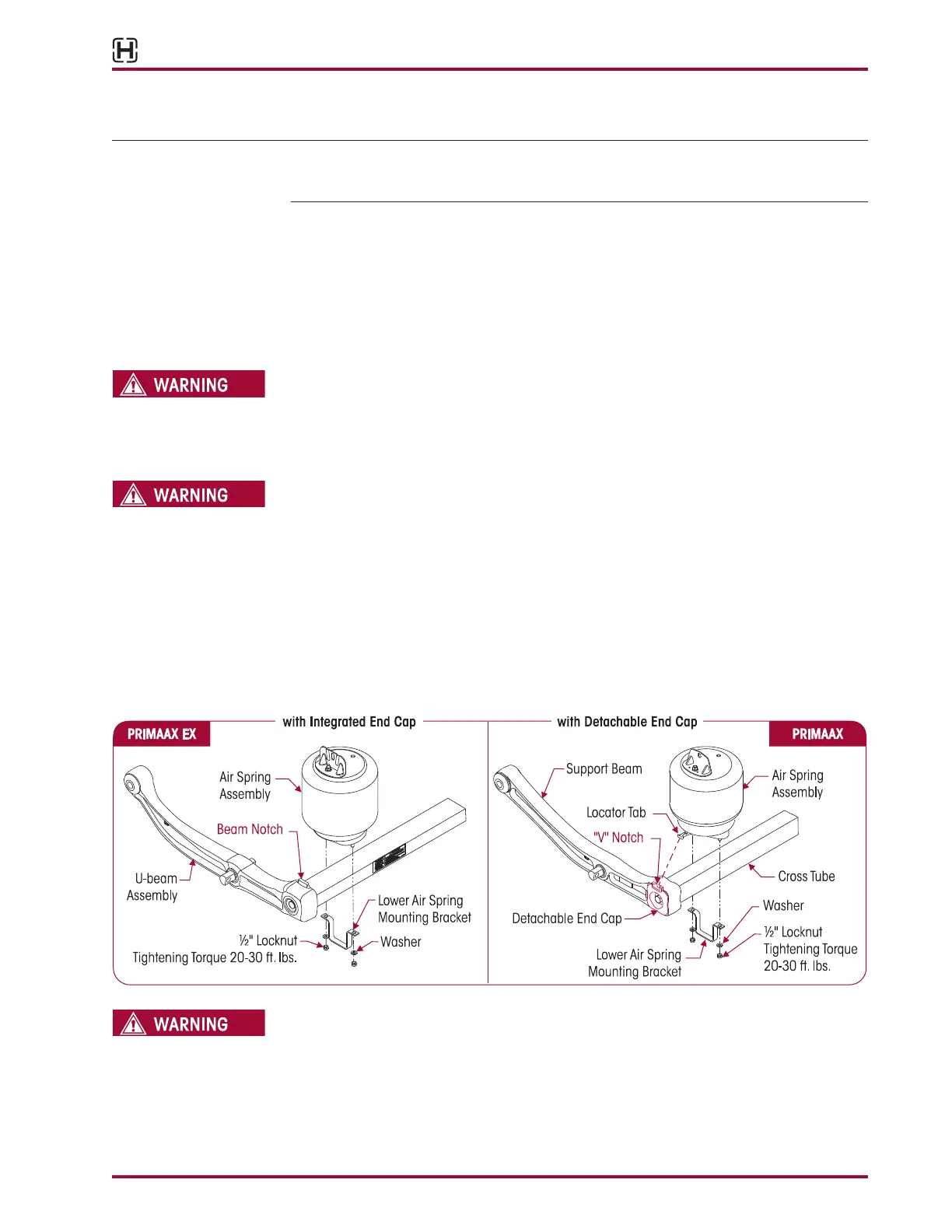

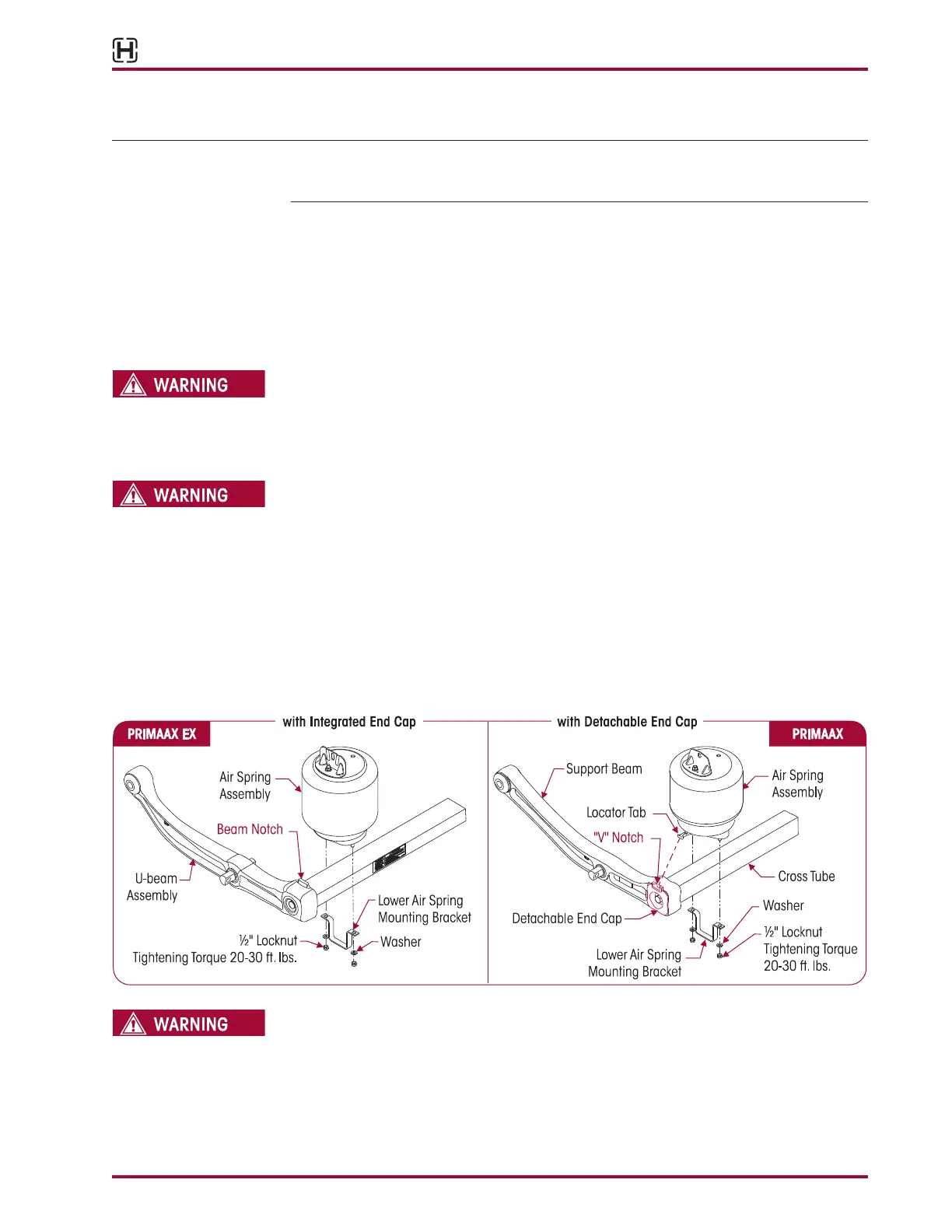

7. Lubricate the lower mounting fasteners of the air springs with penetrating oil. This will help

prevent the air spring mounting studs from breaking during the removal process.

8. Remove the lower mounting fasteners from the air springs using HAND TOOLS only to dis-

connect from the cross tube, see Figure 8-32.

FIGURE 8-32

SERVICE HINT THE USE OF A FLOOR JACK EQUIPPED WITH A FOUR INCH SUPPORT PLATE IS MANDATORY TO

SUPPORT THE SUPPORT BEAM AND CROSS TUBE ASSEMBLY. DO NOT USE A BOTTLE JACK. THE

USE OF A BOTTLE JACK WILL NOT ENGAGE THE CROSS TUBE TO FACILITATE SAFE LOWERING AND

RAISING OF THE SUPPORT BEAMS AND CROSS TUBE ASSEMBLY. FAILURE TO DO SO CAN CAUSE

COMPONENT DAMAGE OR RESULT IN PERSONAL INJURY.

Loading...

Loading...