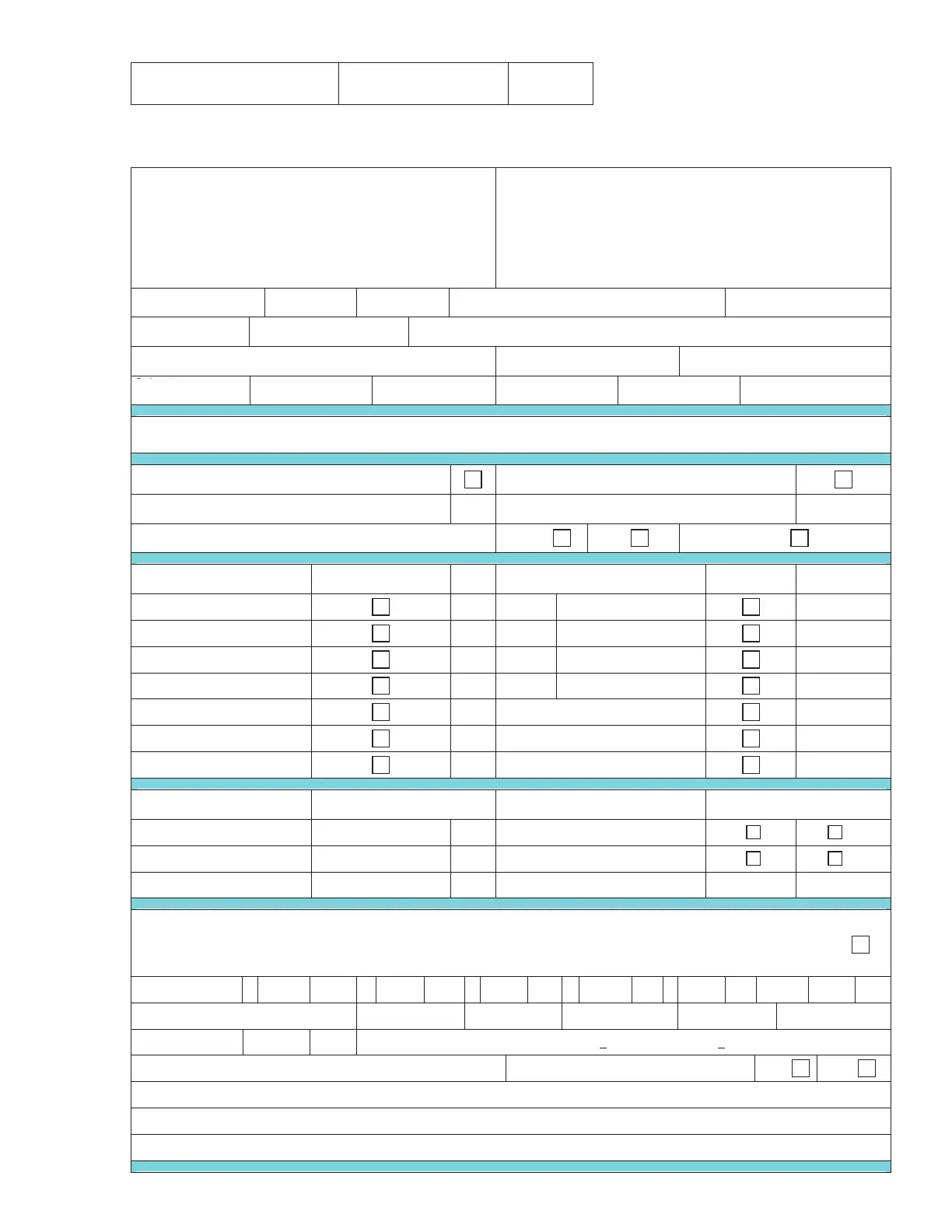

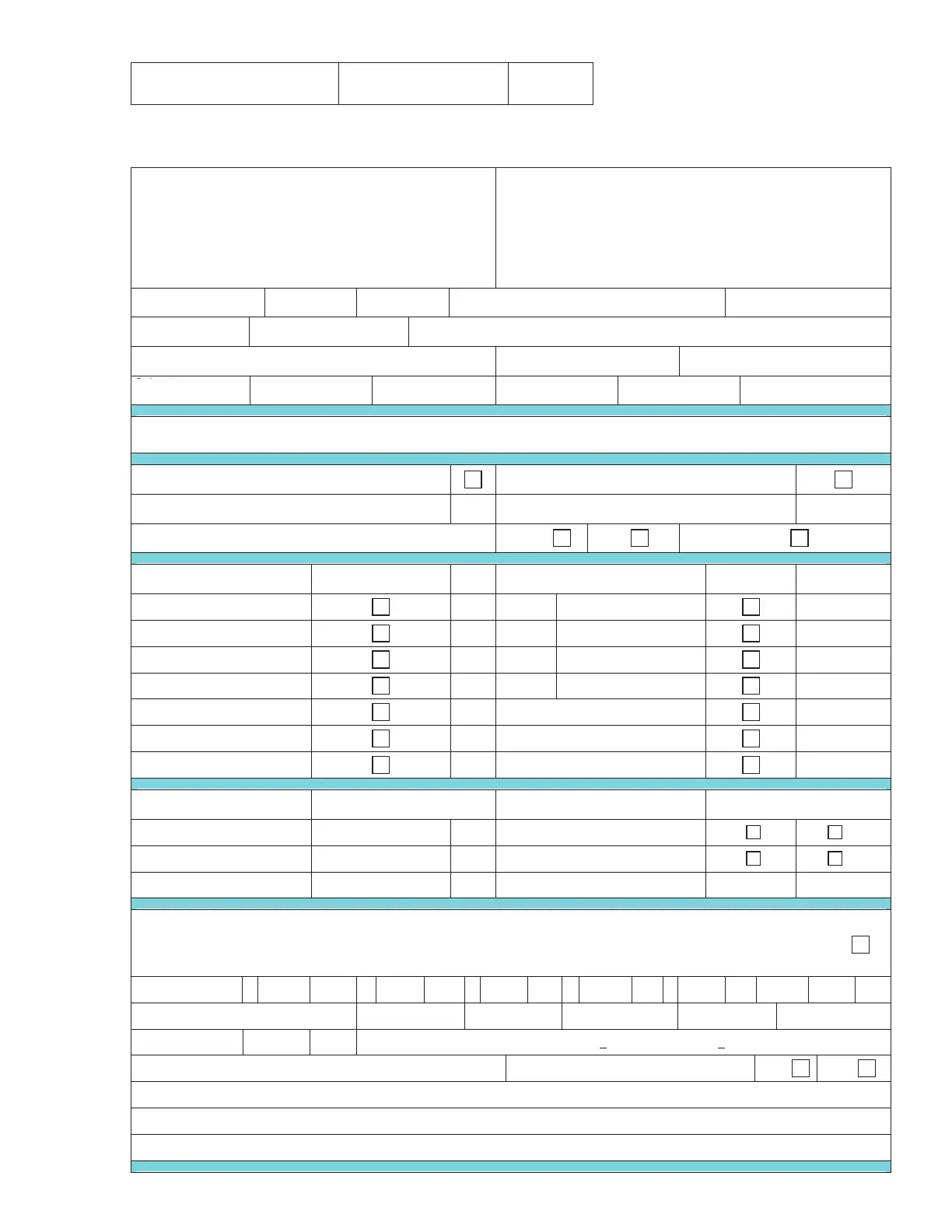

Manufacturing site./Year

Order no.:

Sheet:

1/3

Billing Address Customer no.:

Installation address

Manufacturing year:

Customer center:

Technician no:

Technician’s Name:

Date:

Order date:

Ordered by:

Order no.:

Equipment type:

Part no.:

Hours of use:

Equipment no.:

Serial no.:

Service reference no.:

Delivery date:

Installation date:

Customer inventory no.:

Testing Safety Cabinet Class II Type A2 according to NSF/ANSI 49 - 2002

Installation test

Routine maintenance test

Laboratory Class

Complies with installation rules

Safety Declaration

Yes :

No: Not required:

Visual check

Tested

OK

Rema

rks

Visual check

Tested

OK

Remarks

Values

Type label

DD Direct ducting

NSF – label

TD Thimble ducting

Short operating instruction

ECS Exhaust cooling system

Warnings

AEF 2

nd

exhaust air filter

Attach test label

Height of inflow opening

Check joints of sealing agents

Connection Monitor contact

Check surface for ruptures

Connection Ext blower contact

Safety check UL 3101-1 (2003) Safety check UL 3101-1 (2003)

Ground conductor

< 0,3 ȍ

GFI test sockets

Yes

No

Insulating resistance

> 2 Mȍ

Polarity test ( sockets T5A )

Yes

No

Conductance

< 3.5 mA

Air inflow speed: Method 1 Flow Hood ( DIT )

Direct measuring inflow air volume in the front window opening with the flow hood ( DIT Direct instrument testing )

Front panel in working position 10 in (254 mm), flow hood sealed on the front opening

Inflow air volume 1

Ft³/

min

2

Ft³/

min

3

Ft³/

min

4

Ft³/

min

5

Ft³/

min

Mean

value

Ft³/

min

Air speed = Air volume / Air area Inflow air area KS9: 0,23 m² KS12: 0,30 m² KS15: 0,38 m² KS18: 0,45 m²

Inflow air speed Ft/min Set value : 105 ft/min +

5 ft/min (0,53 m/s + 0,025 m/s)

Air flow on all positions of working opening into safety cabinet Requirement fulfilled

Yes

No

Remarks:

Test Record

Loading...

Loading...