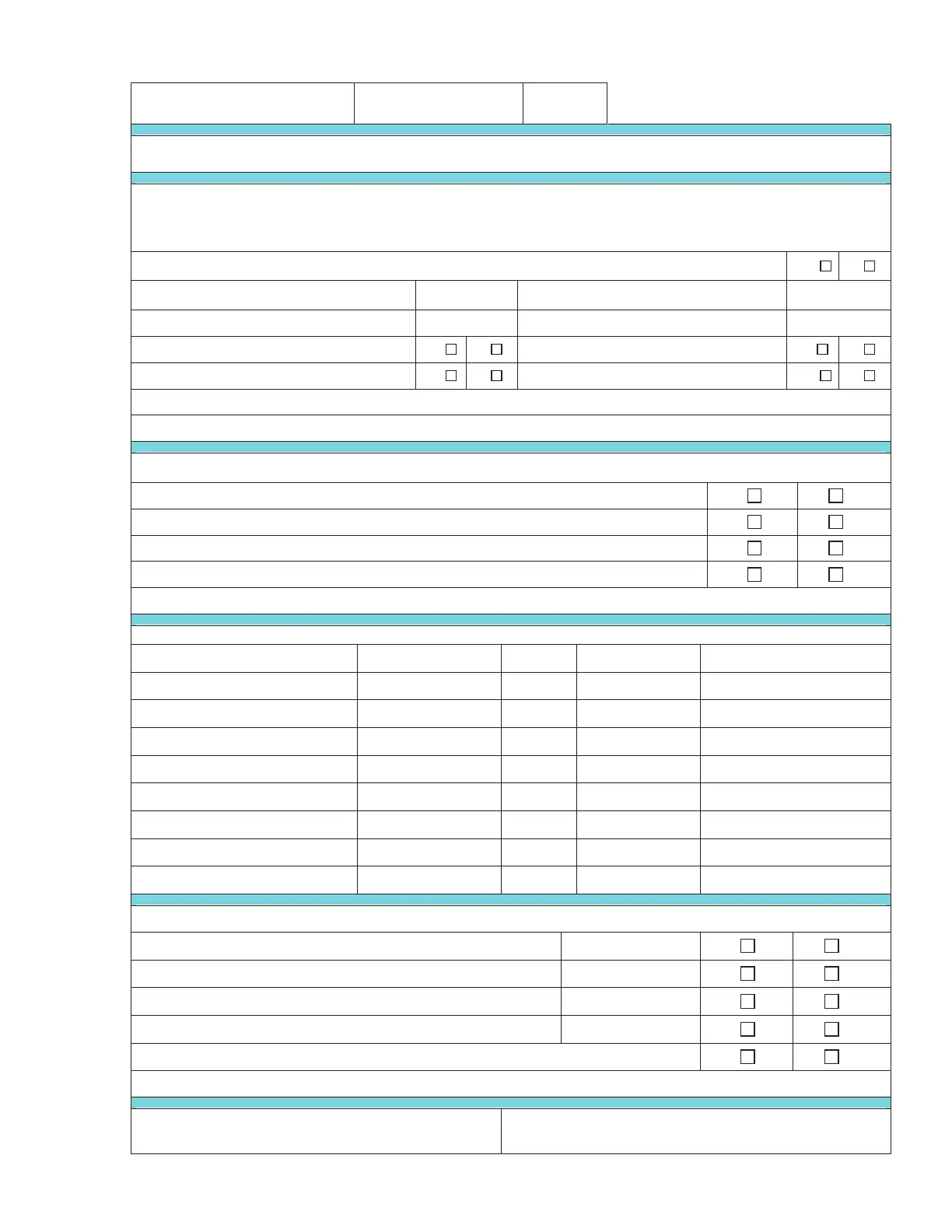

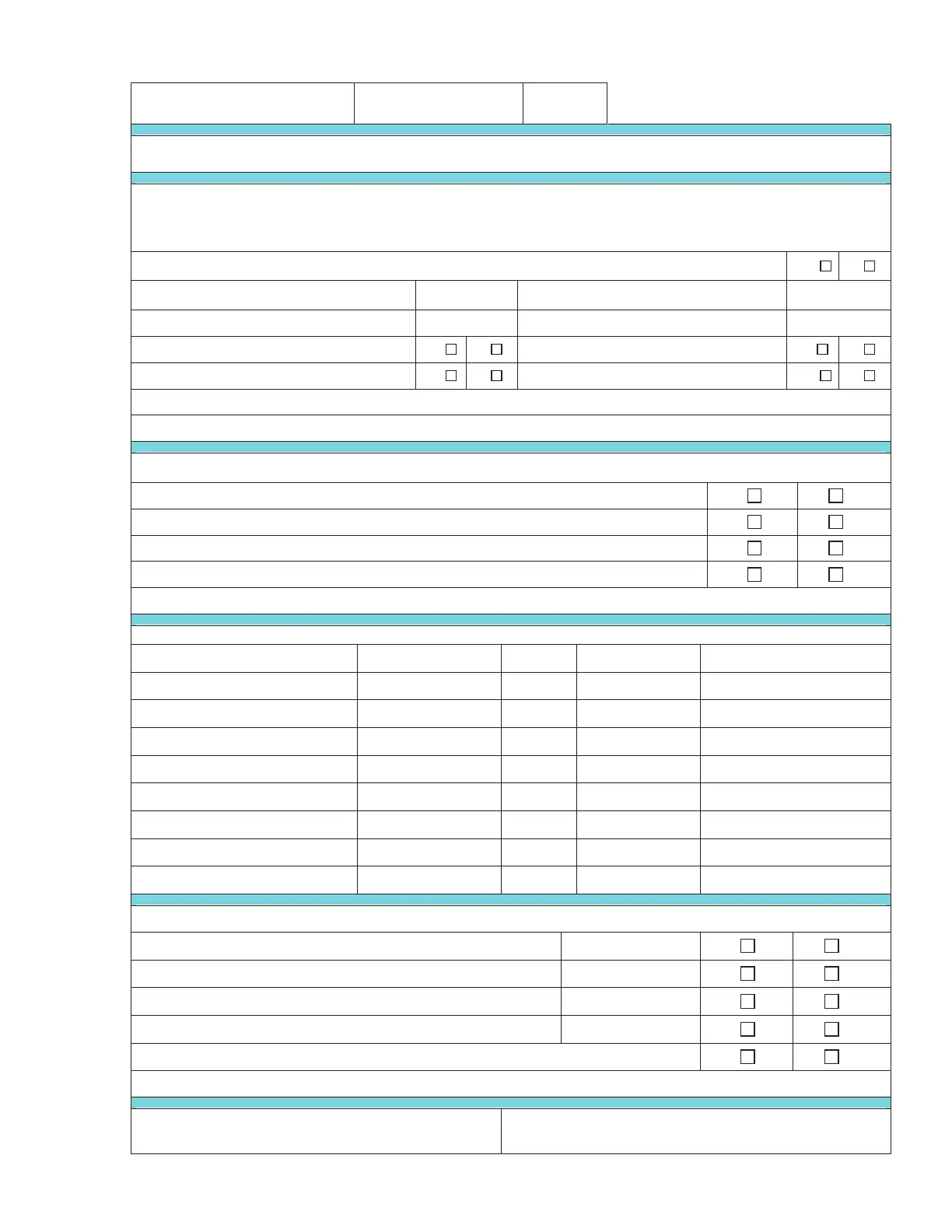

Manufacturing site / Year

Order no.:

Sheet:

3/3

Testing Safety Cabinet Class II Type A2 according to NSF/ANSI 49 - 2002

Filter leakage test

Test aerosol Polyalphaolefin (PAO), Emery 3004 Synthetic Hydrocarbon 4 CST Fluid, laminator plate removed,

distance sensor-filter 1 in, scan speed 2 in/sec

Test connection for filter integrity test available

Yes

No

Supply air filter

Remarks

Values

Exhaust air filter

Remarks

Values

Filter class ( 99.99 % / 0.3 µm ) Filter class (99,99 % / 0,3 µm )

Filter sealing and area tested Yes

No Filter sealing and area tested Yes No

Filter class requirements fulfilled Yes

No Filter class requirements fulfilled Yes No

Remarks:

Airflow smoke patterns test (with e.g. titanium tetrachloride)

Downflow test [4 in (10 cm) above window opening, centerline work surface, no dead spots or reflux]

Yes

No

View screen retention test [1 in (2.5 cm) behind front window, 6 in (15 cm) above window opening,

no dead s

Yes No

Work opening edge retention test [ app. 1.5 in (4 cm) outside cabinet, no smoke drawn to the work surface

or billow over the work area

Yes No

Sash / window seal test [2 in (5 cm) from sides and along top of work area, no smoke shall escape from

the cabinet

Yes

No

Remarks:

Measuring instruments and their application

Measuring instrument

Measuring instrument

no.:

Calibration

note no.:

Calibration date Application

Digital Safety Inspector

Electrical leakage,

ground resistance test

GFI Circuit Tester

Electrical leakage, ground

resistance and polarity test

Anemometer Down flow velocity test

Flow Hood Airdata Multimeter Inflow air volume test

Photometer / Particle counter Filter leakage test

Aerosol generator ./. ./. ./. Filter leakage test

Test aerosol ./. ./. ./. Filter leakage test

Smoke tubes ./. Use before: Airflow pattern test

TEST RESULTS ACCORDING TO NSF 49, Annex F

Retaining at working opening Requirement fulfilled

Yes

No

Integrity of exhaust air filter Requirement fulfilled

Yes

No

Product protection (class II only) Requirement fulfilled

Yes

No

Cross contamination (class II only) Requirement fulfilled

Yes

No

Instrument complies with state of the art as per NSF / ANSI 49 with regards to personal protection

Yes

No

Remarks:

Date / Signature Customer

Date / Signature Service Engineer

Loading...

Loading...