Page 9For technical questions, please call 1-888-866-5797.Item 57363

Installing a Non-threaded Grinding Wheel

or Cut-Off Wheel (wheels sold separately)

1. For a Grinding Wheel, it MUST be:

• rated to at least 6500/min

• no larger than 9" in diameter

• fitted with a 5/8" round arbor hole

• from 0.035" to 0.3" thick

• a type of grinding wheel suitable for

surface grinding, not edge grinding

• dry and clean

• proven undamaged by inspection

For a Cut-Off Wheel, it MUST be:

• rated to at least 6500/min

• no larger than 9" in diameter

• fitted with a 5/8" round arbor hole

• from 0.035" to 0.3" thick

• suitable for edge grinding, not surface grinding

• dry and clean

• proven undamaged by visual inspection

WARNING! TO PREVENT SERIOUS

INJURY, When using a Cut-Off Wheel, a

wheel guard designed specifically for Cut-Off

Wheels (not included) must be installed for

adequate protection if the wheel fails.

WARNING! TO PREVENT SERIOUS INJURY,

Use only 7" grinding wheels with 7" guards.

Use only 9" grinding wheels with 9" guards.

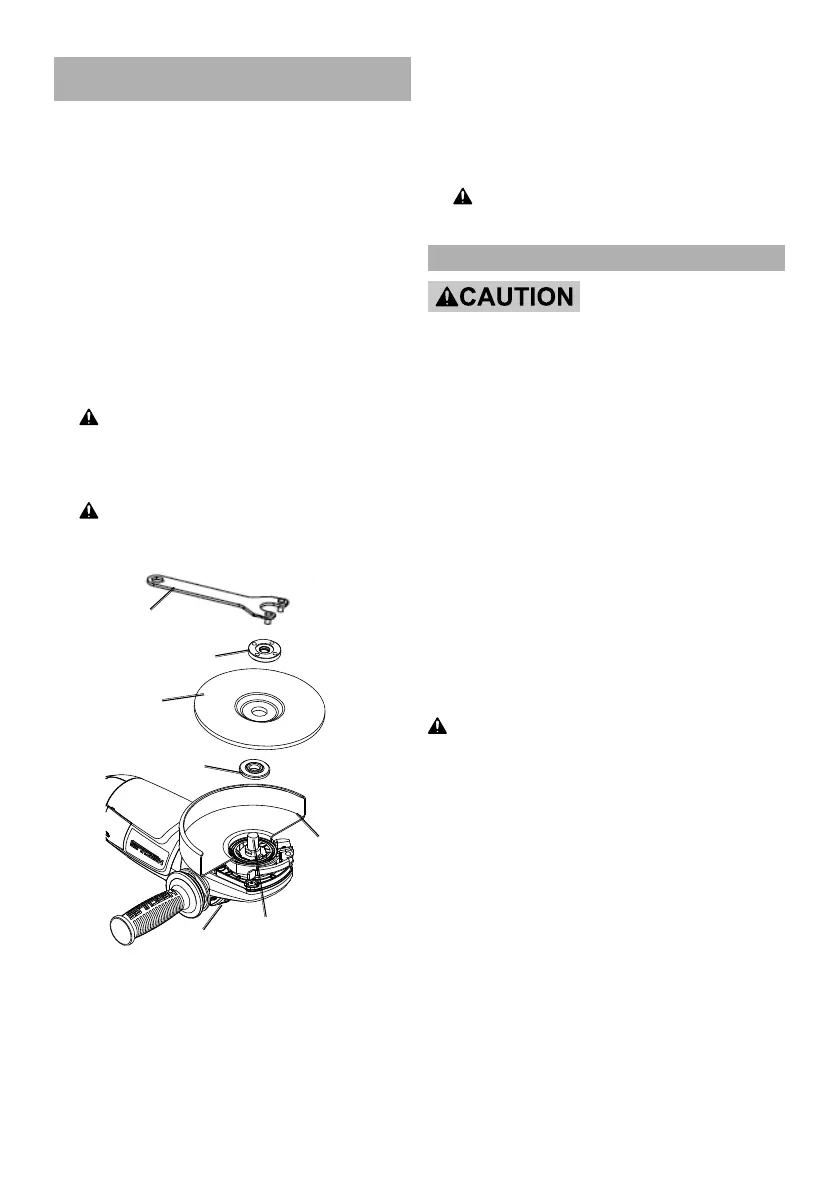

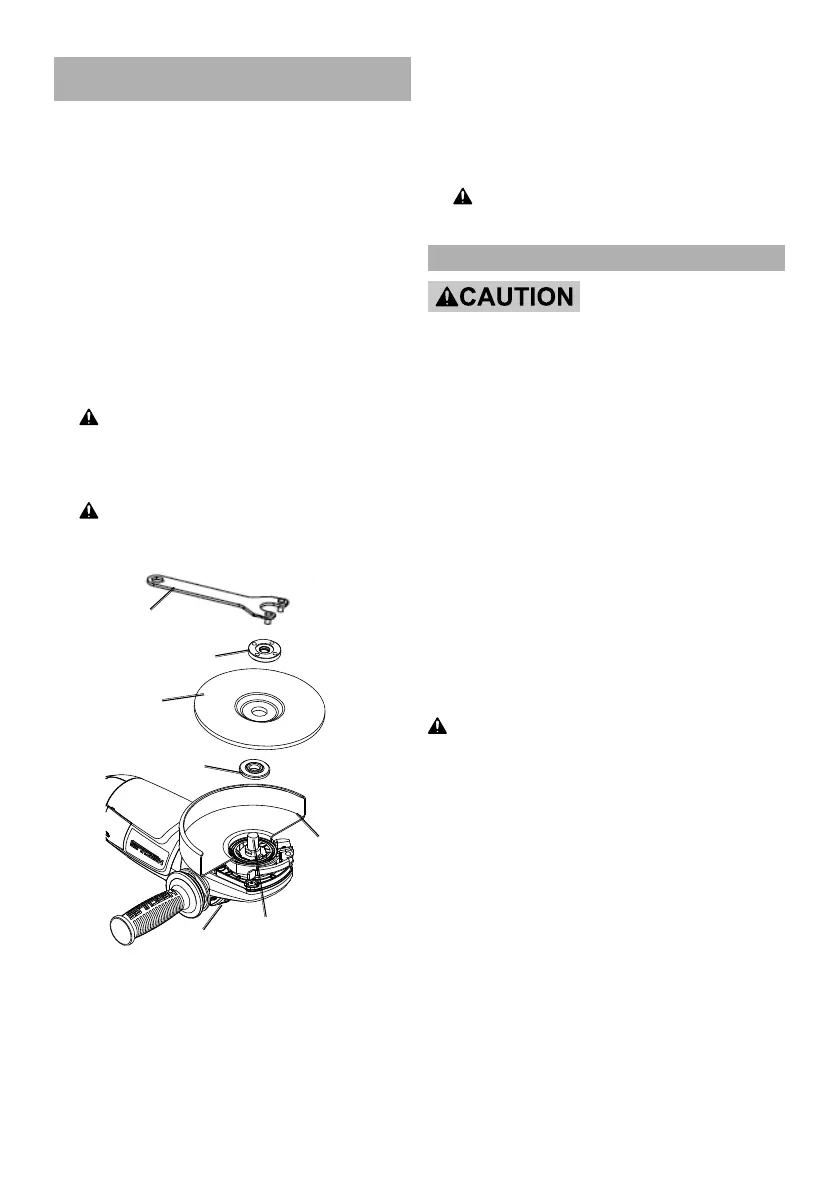

Wrench

Flange Nut

Grinding

Wheel

Flange

Wheel

Guard

Spindle

Spindle Lock

2. Press in and hold the Spindle Lock to

prevent the Spindle from turning.

3. Remove the Flange Nut. Keep the

Flange in position on the Spindle.

4. Thread the Flange Nut onto the Spindle.

Wrench tighten only enough so that the

wheel is securely held on the spindle.

WARNING! TO PREVENT SERIOUS INJURY,

do not overtighten Flange Nut. Overtightening

can damage the wheel, causing wheel failure.

Installing a Threaded Accessory

TO PREVENT INJURY: Wear heavy-duty work

gloves when handling wire wheels and brushes.

These accessories are sharp and can cause

injury. Do not exceed maximum rated speed of

brush. Do not use a damaged brush. Replace

damaged brushes immediately. Damaged

or worn brushes will forcefully shoot wires

into all objects not covered by the guard.

1. The accessory MUST be:

• rated to at least 6500/min

• no larger than 9" in diameter

• fitted with a threaded opening of 5/8" x 11 TPI.

• undamaged

• a sanding disc and backing pad, a sanding

flap disc, a wire wheel or a wire cup

brush (accessories not included).

2. Press in and hold the Spindle Lock Button

to prevent the Spindle from turning.

3. Remove the Flange Nut and the

Flange and keep in a safe place.

4. Thread disc accessory firmly onto the

Spindle. Wrench tighten onto the Spindle.

WARNING! TO PREVENT SERIOUS INJURY,

Use only 7" grinding wheels with 7" guards.

Use only 9" grinding wheels with 9" guards.

Loading...

Loading...