for the technician

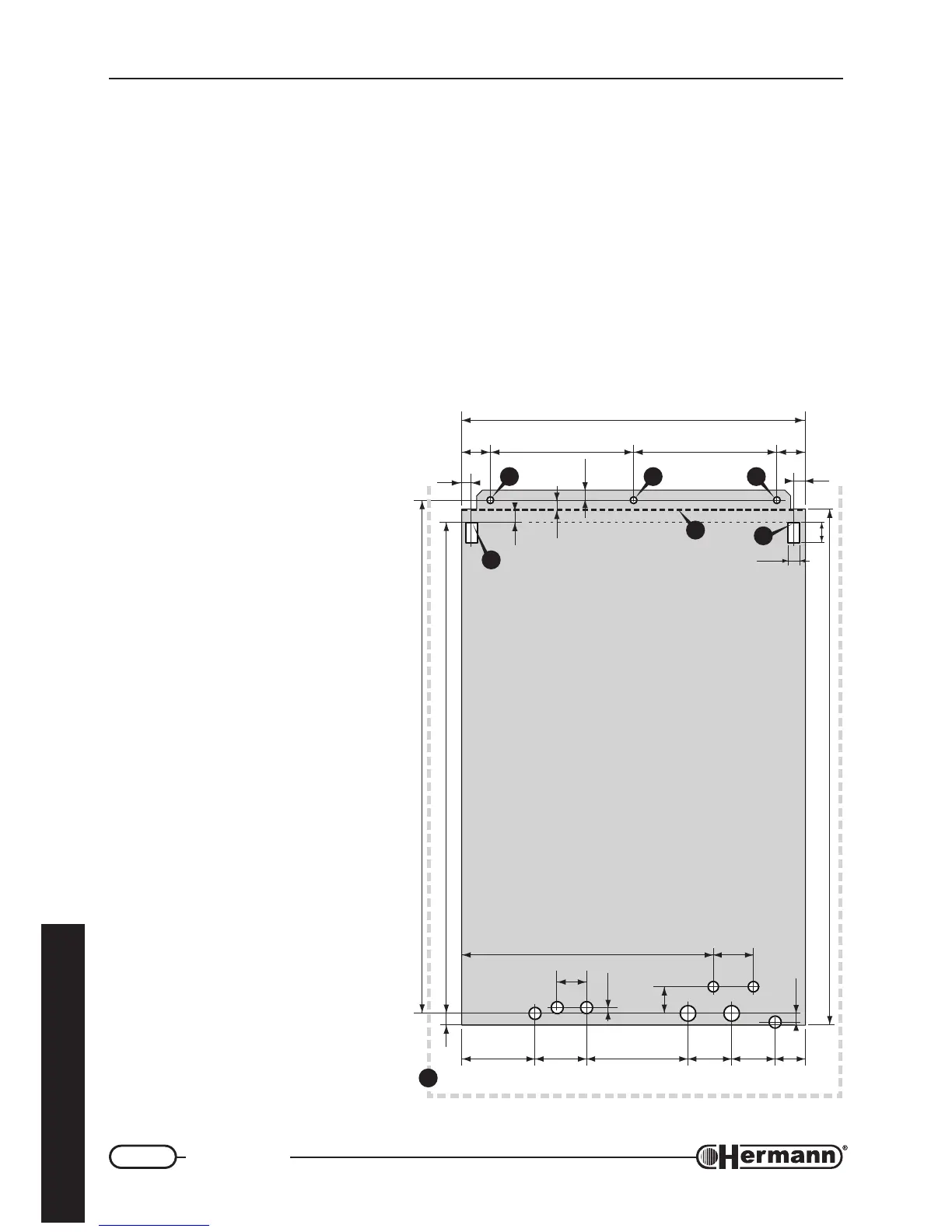

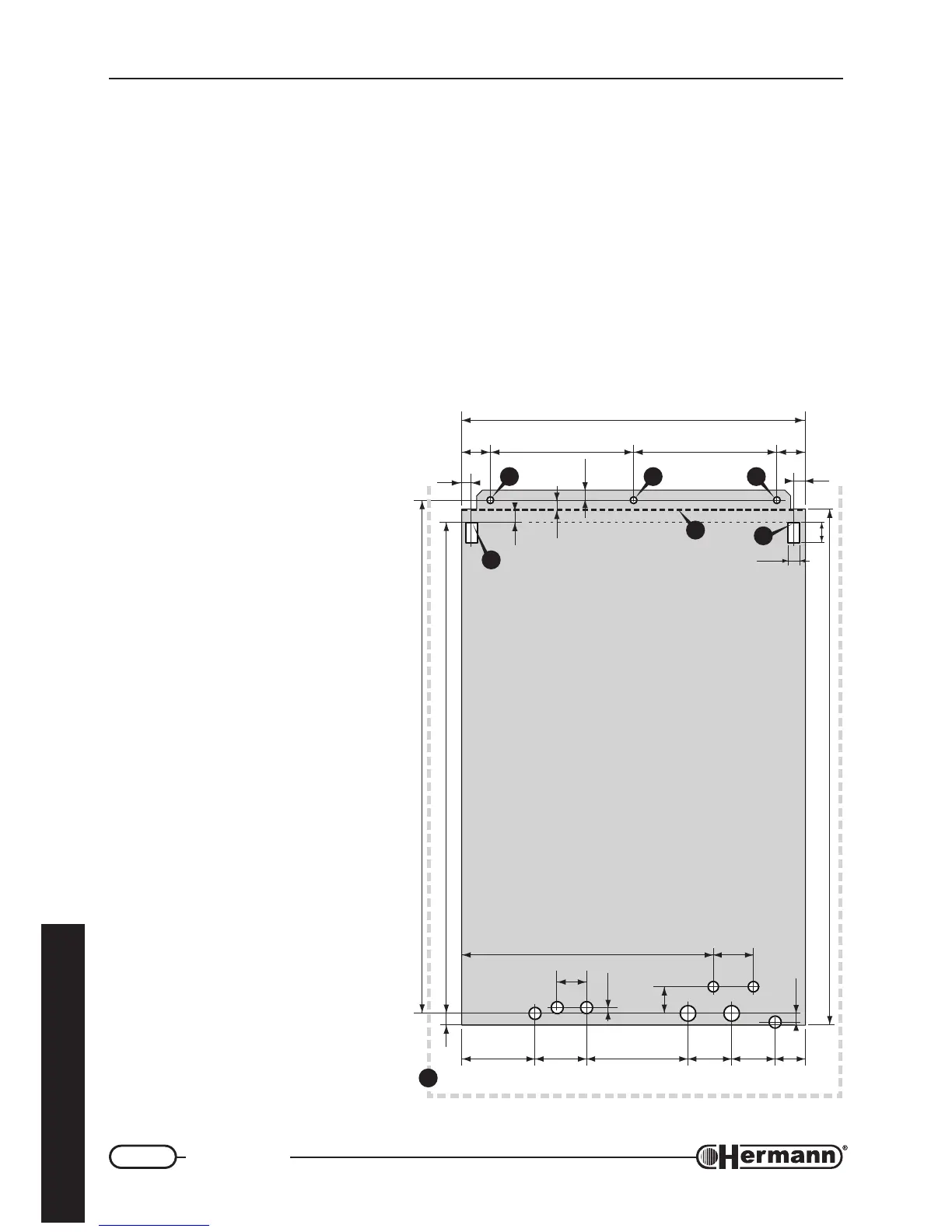

Boiler hanging

REMARK: A re-utilizable metal jig can be ordered separately, so as to facilitate connections and

fixing points positioning (when the standard connection kit is used). If the standard connection

kit is not used, refer to the “Dimensions” drawing (Technical Data section) for the position of the

connections directly on the boiler.

— Consider gas boiler size and sufficient clearances [E] for servicing/repair. It is recommended:

50 mm left, 150 mm right and 300 mm on lower side;

— To fix the boiler with wallplugs (“stud” type with nut), center the relevant wall holes as regards to

[A] points. To hang it with open hooks, place hooks in correspondence with [B] points.

— Using the jig or respecting the measures indicated in the figure, fix up electrical connections

and all ducts for heating flow and return, cold water, hot water and gas.

— Hang the boiler to the wallplugs

or hooks, using the holes ([A] for

the wallplugs and [B] for the open

hooks).

— Remove the plastic caps from

the boiler connections prior to

connecting boiler to the pipework.

REMARK: To facilitate boiler

connection, it is possible to

remove temporarily the lower

grid, unscrewing its four screws.

— As far as air inlet and flue outlet

ducts are concerned (forced

draught models), please refer to

“Flue systems” paragraph, where

measures are referred to the

upper edge of boiler’s body [D].

A

B

D

E

A A

B

250 250 50

20

35

50

600

18

18

439

128

RC

FRI

M

G

TAL

90

52

177 76 69 60

70

18

891

900

766R01

86220

10

47

13

11

14

C Hot water outlet (1/2")

RI Re-circulation Return

(optional - 1/2")

F Cold water inlet (1/2")

R System Return (3/4")

M System Flow (3/4")

G Gas (1/2")

L Electric Line

TA Room thermostat

Loading...

Loading...