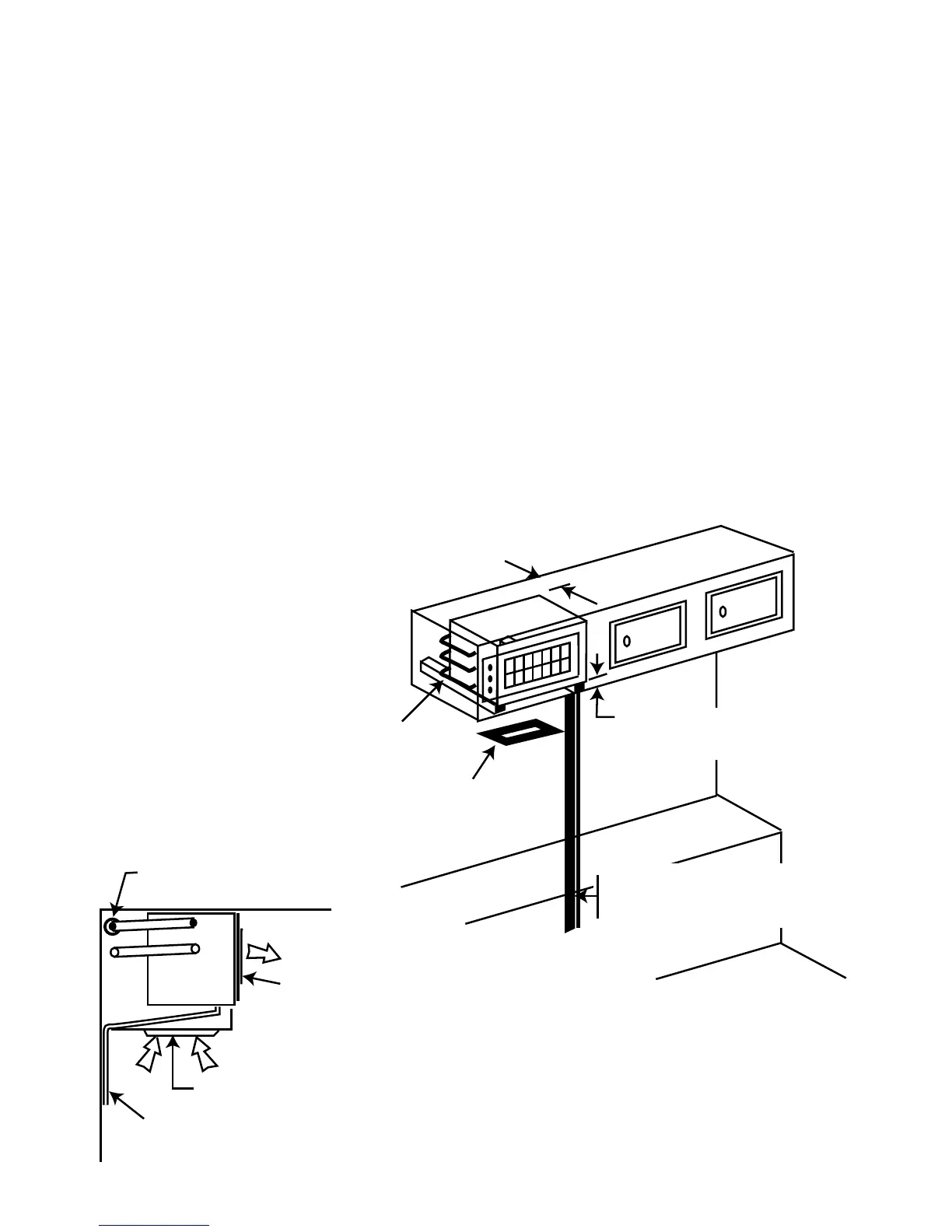

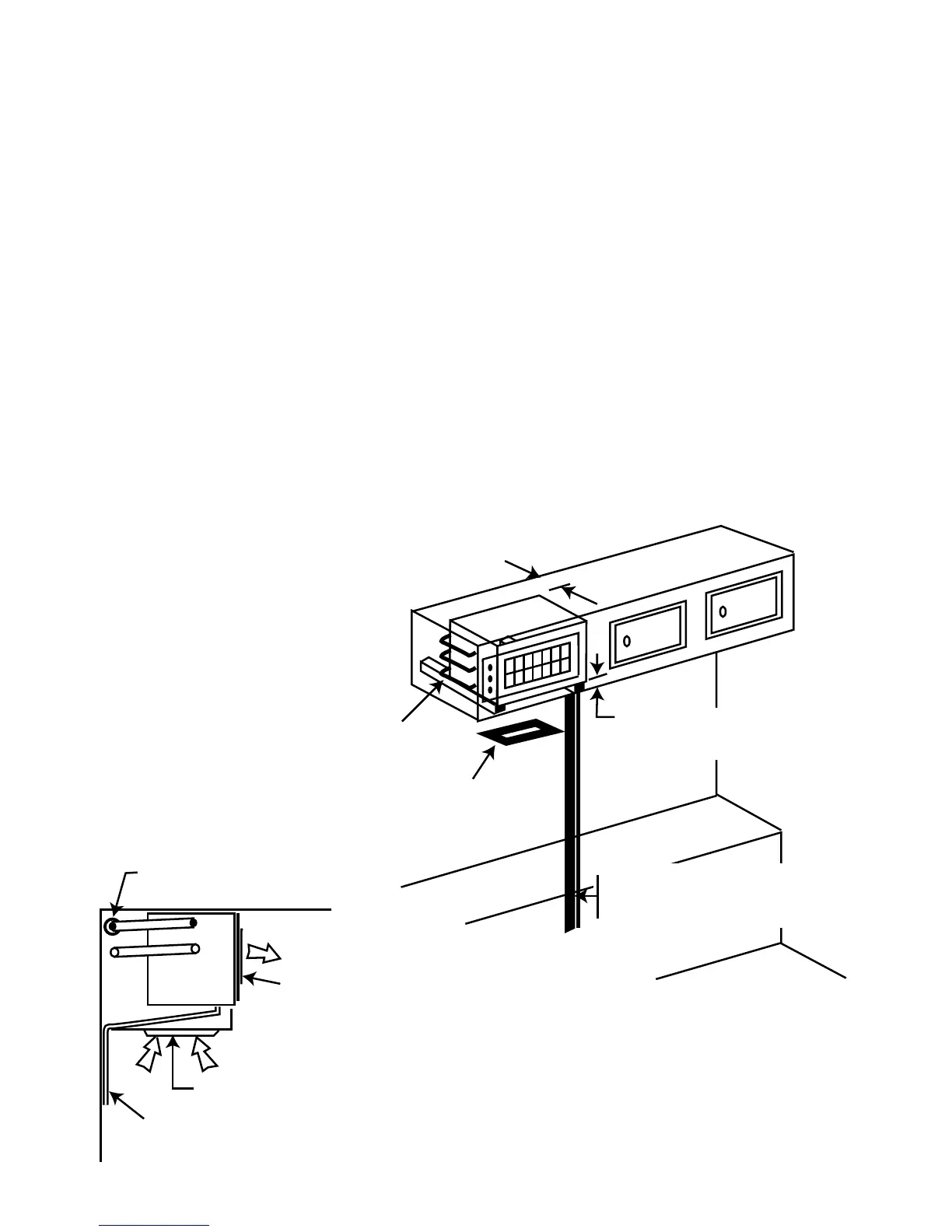

90 mm min.

75 mm between pan of unit and

bottom to allow for drain fall

Refrig. pipes cross

back of enclosure

and come round on

LH. side to give flexibility

2 return air filter

assy. inset to bottom

of cupboard

Refrig. lines, drain hose,

electrical cable

(cover with moulding)

Figure 6

PIPE INSTALLATION & CONTROL WIRING

The pipe work consists of a

1

/4” tube (liquid line), and a

3

/8” tube (return gas)

running between the Con/set and the A/H. The

3

/8” line must be insulated with 10x

10 mm foam rubber insulation.

Connection is made at the back of the Con/set. Pipe work may be run internally to

the A/H, or may be run through holes in the floor and run externally to a

convenient re-entry point, or the pipes may be built into the wallspace during van

construction. N.B. Pipework installed in walls must be well insulated to avoid

“sweating” and possible long term moisture damage.

The control wiring will normally follow the pipework and be taped to it. N.B. If

the control cable is to be run externally, then it must be run in a suitable conduit.

Now refer to the A/H installation, after which we return to the Con/set to open up

the refrigeration circuit and fit the louvre panel.

Loading...

Loading...