GH F33 BDA

Chapter 3

Maintenance

3.1 Generally

3.1.1 Index

This chapter contains main instruction for technically qualified personnel to carry out minor

inspections and repairs, such as:

- Periodical inspections of engine

- Maintenance of engine components

- Trouble shooting

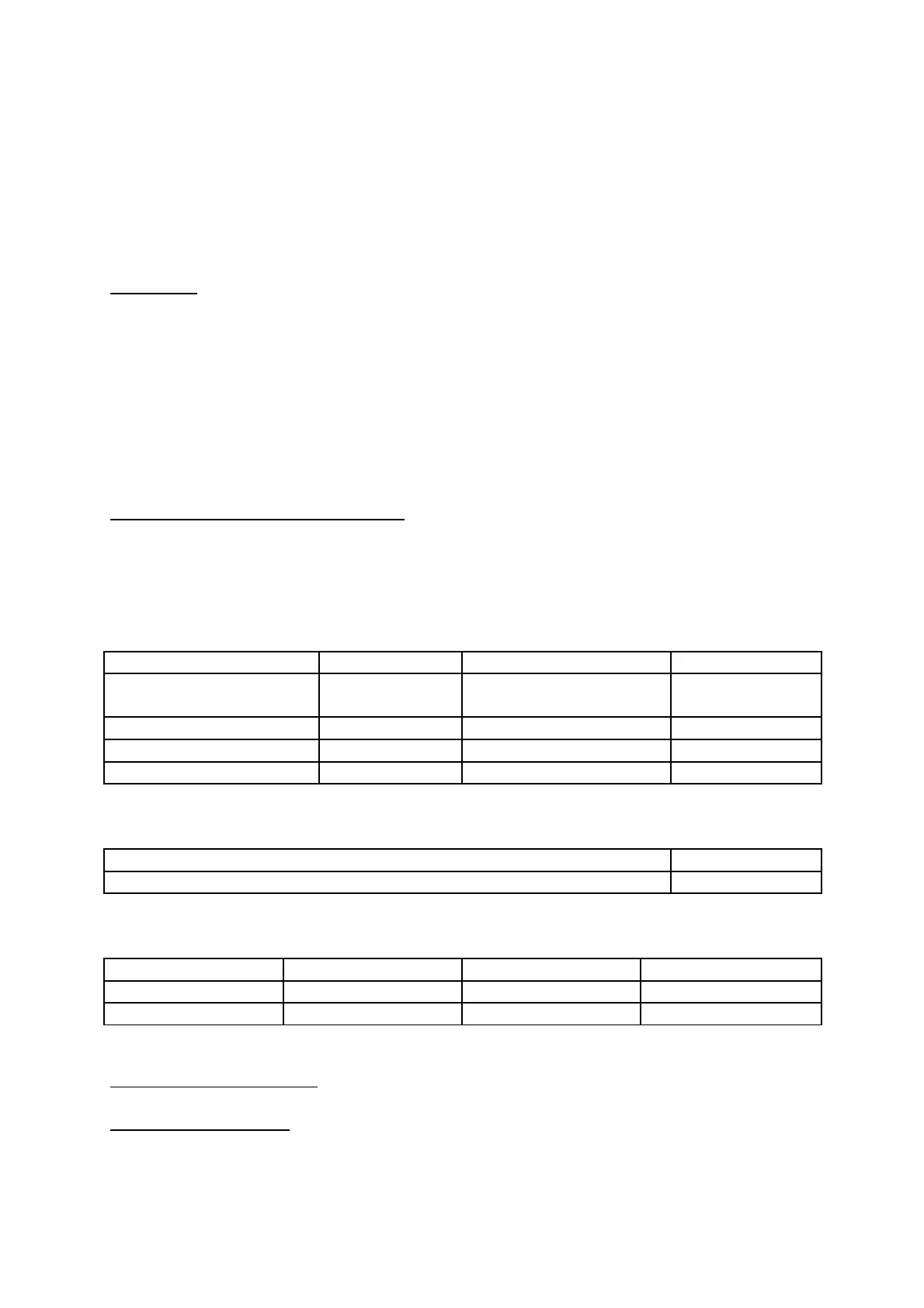

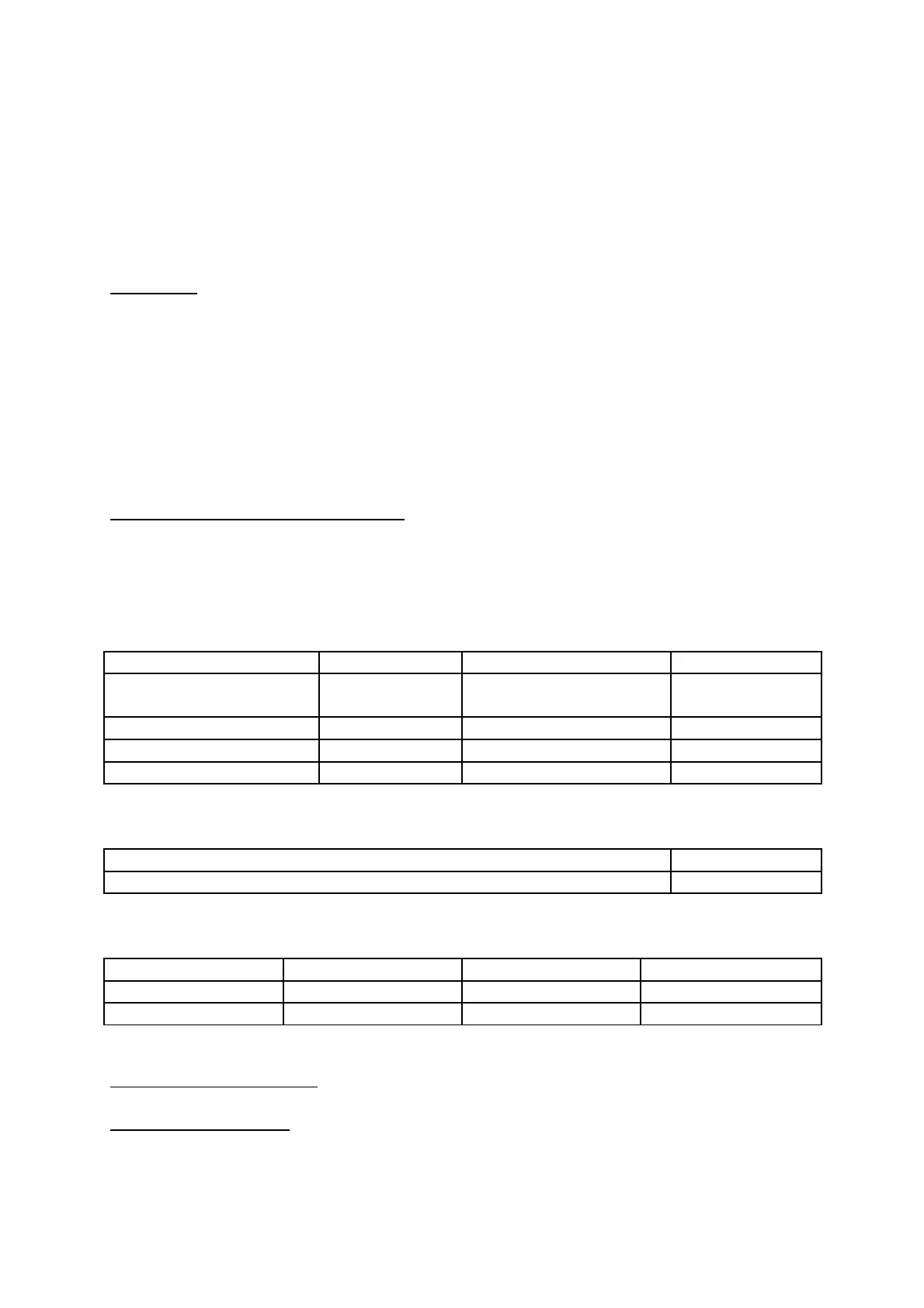

3.1.2 Tools , special tools and torques

Description and sizes of tools are indicated in metrical system and can be purchased in special

shops.

Tools:

Description Size Description Size

Torque wrench 0-50 Nm Hexagon head socket

wrench

SW 5

Engineers’ wrench SW 10 Engineers’ wrench SW 13

Engineers’ wrench SW 17 Socket wrench SW 24

Screwdriver Sparkplug wrench 20.6/20.8

Special tools:

Flywheel-withdraw W 85

Piston ring clamp (piston – mounting assistance W 108/15

Initial Torque Values

Description Torques Description Torques

M6 9,6-11 Nm M8 23-28 Nm

M10 45-50 Nm

3.2 Maintenance Intervals

3.2.1 Daily Inspections

Daily inspection should be realized conscientious before every operation. Pay attention to

following instructions:

Stand: 02.02.05 DOC_F33_B_E_0.01

Loading...

Loading...