--- 18 ---

Type of

crown molding

To process crown molding at

positions and in Fig. 24

To process crown molding at

positions and in Fig. 24

Miter angle

setting

Bevel angle

setting

Miter angle

setting

Bevel angle

setting

Right 35.3˚

( mark)

Left 30˚

( mark)

Left 35.3˚

( mark)

Left 30˚

( mark)

45˚ type

Right 31.6˚

( mark)

Left 33.9˚

( mark)

Left 31.6˚

( mark)

Left 33.9˚

( mark)

38˚ type

3

1 4

2

Table 4

(8) Crown molding cutting

This machine can cut two types of crown molding workpieces by combining the miter and bevel cutting

operations (for USA).

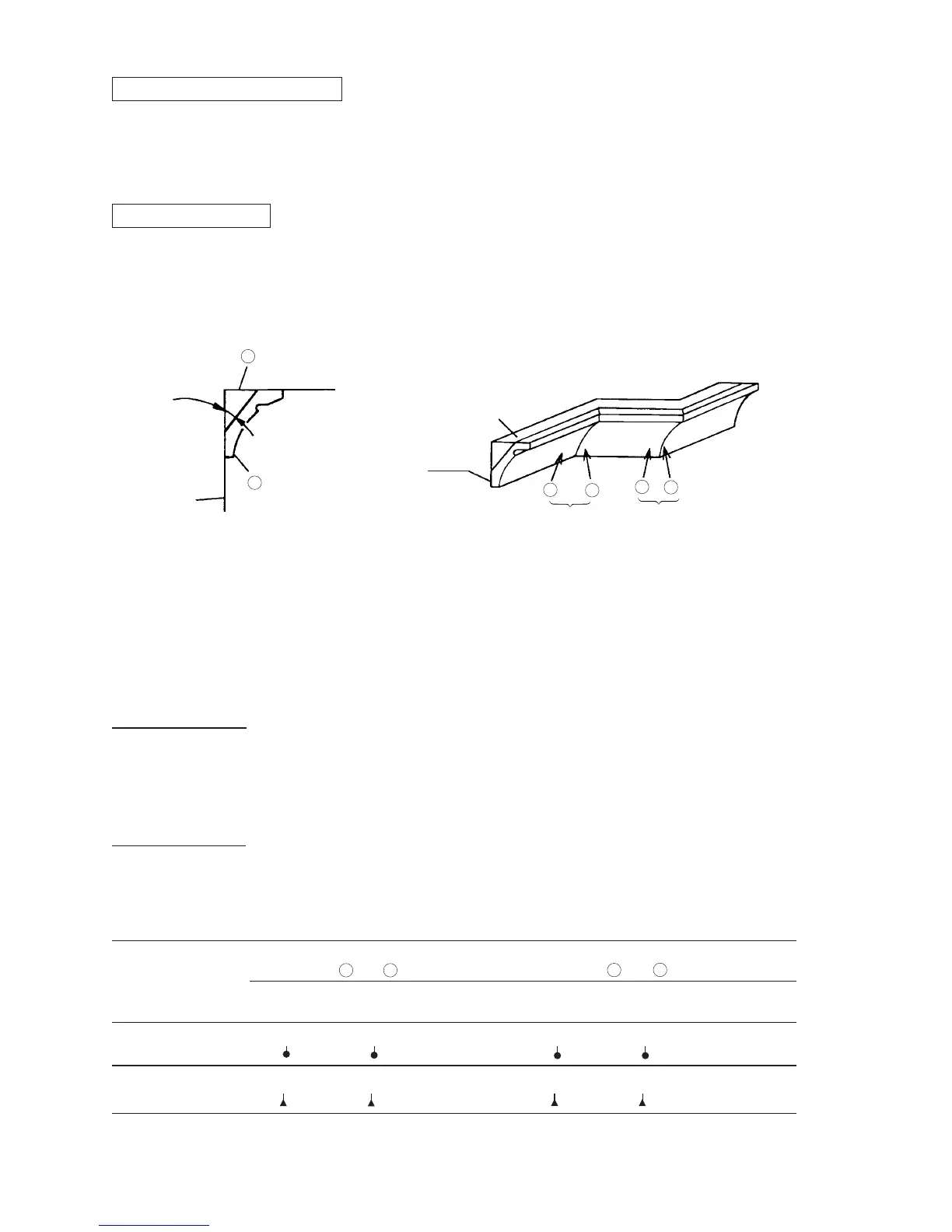

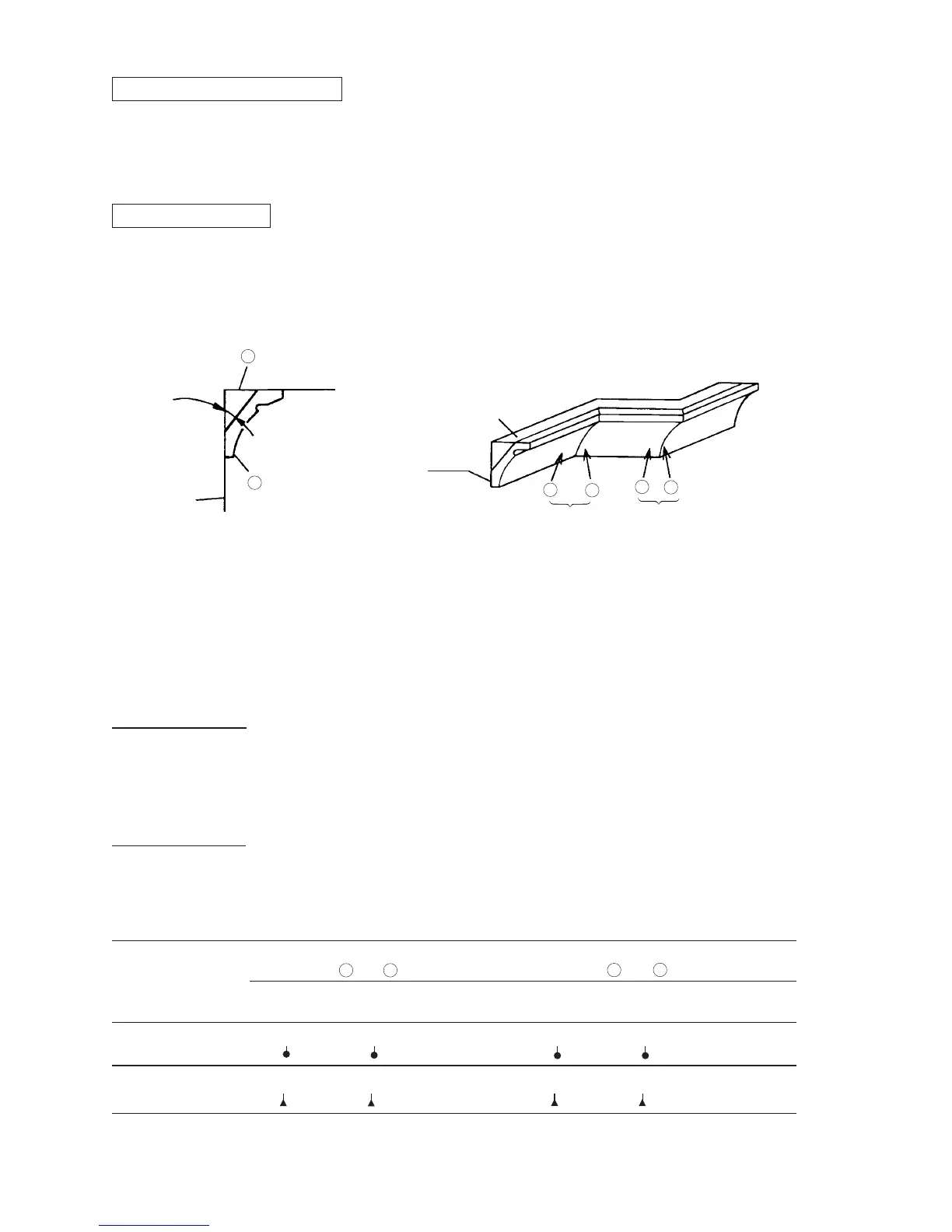

Figure 24 shows two common crown molding types having angles of (θ) 38˚ and 45˚. For the typical crown

molding fittings, see Fig. 25.

(7) Compound (miter + bevel) cutting

Compound cutting can be accomplished by combining the miter cutting and bevel cutting operations described

in paragraphs (5) and (6) above. (For details, please refer to the Instruction Manual.) When the saw blade

section (head) is inclined 45˚ to the right and left, the table can be turned up to 45˚ to the right and left.

The table below shows the miter angle and the bevel angle settings that are ideal for the two crown molding

types.

NOTE: For convenience, positive stops are provided for both the miter setting (left and right 31.6˚) and

the bevel setting positions.

For miter cut setting

If the turn table has been set to either of the angles described, move the turn table adjusting the side

handle a little to the right and left to stabilize the position and to properly align the miter scale and the tip of

the indicator before the operation starts.

For bevel cut setting

Move handle on miter section to the right and left and check that the position is stable and the angle scale

and the tip of the indicator are properly aligned. Then tighten the clamp lever.

Upper surface ceiling

Wall

Lower surface

Fig. 24 Fig. 25

Outside corner

Ceiling

Wall

Inside corner

A

B

2

3

θ˚

4

1

Loading...

Loading...