12

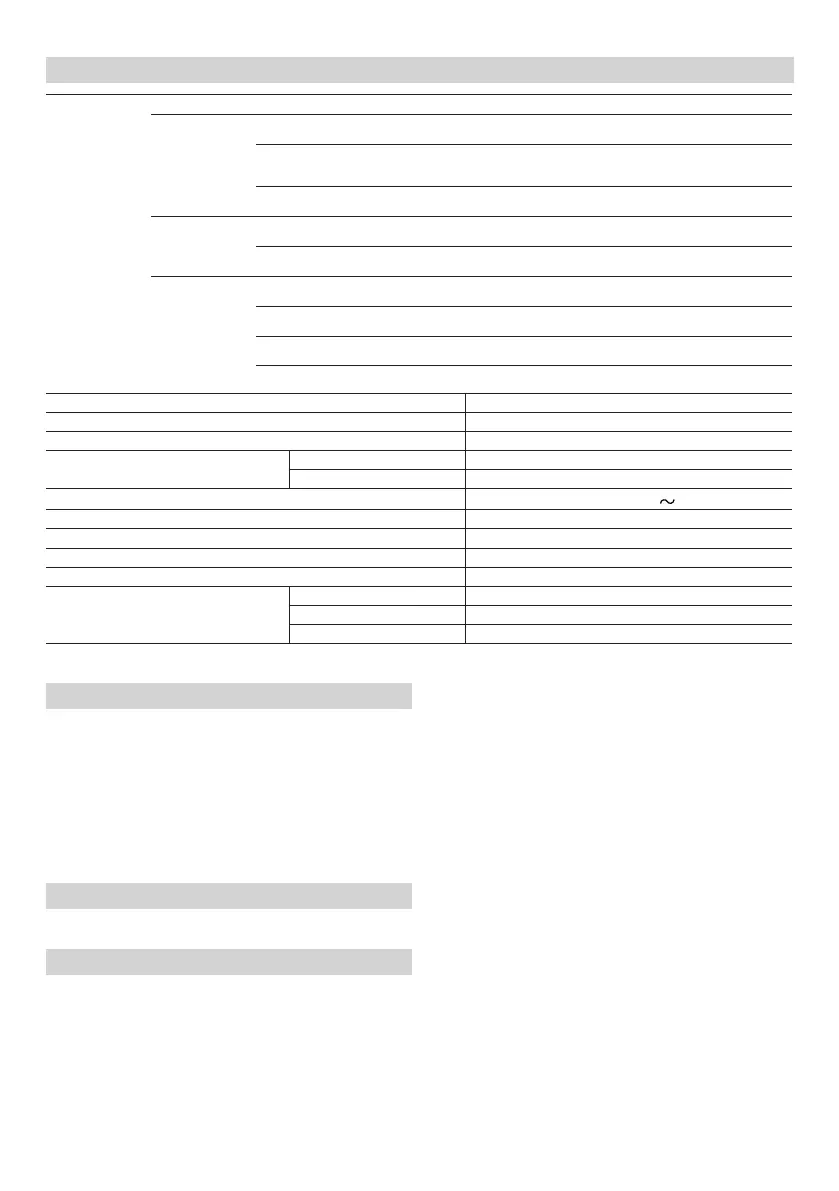

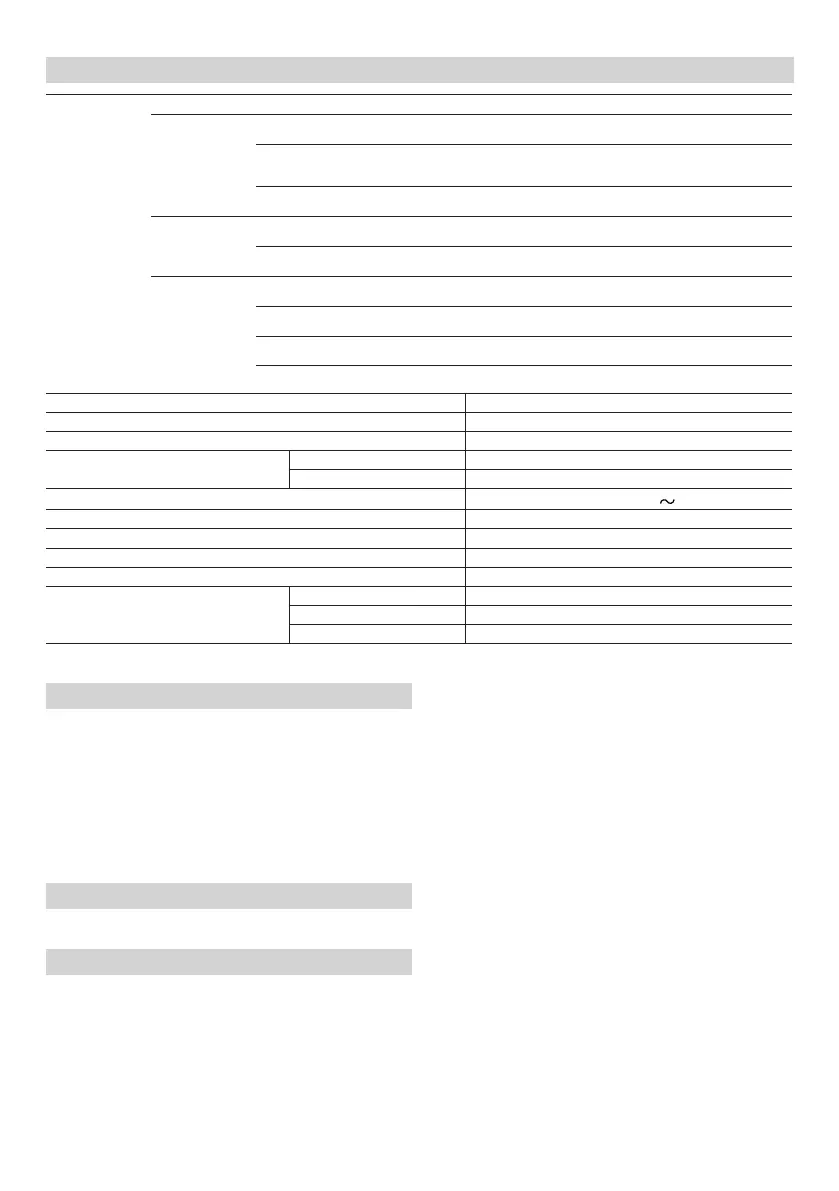

SPECIFICATIONS

Max.

sawing

dimension

Head Turntable Max. sawing dimension

Miter 0 0 Max. Height

Max. Width

105 mm

312 mm

0 Left 45°

or

Right 45°

Max. Height

Max. Width

105 mm

220 mm

0 Right 57° Max. Height

Max. Width

105 mm

170 mm

Bevel Left 45° 0 Max. Height

Max. Width

68 mm

312 mm

Right 45° 0 Max. Height

Max. Width

43 mm

312 mm

Compound Left 45° Left 45° Max. Height

Max. Width

68 mm

220 mm

Left 45° Right 31° Max. Height

Max. Width

68 mm

265 mm

Right 45° Right 45° Max. Height

Max. Width

43 mm

220 mm

Right 45° Left 31°

Max. Height

Max. Width

43 mm

265 mm

Saw Blade Dimensions (oD × iD × Thickness) 305 mm × 25.4 mm × 2.3 mm

Miter Cutting Angle Right 0° – 57°, Left 0° – 45°

Bevel Cutting Angle Right 0° – 45°, Left 0° – 45°

Compound Cutting Angle

Bevel (Left) 0° – 45° Miter (Left) 0° – 45°, (Right) 0° – 31°

Bevel (Right) 0° – 45° Miter (Right) 0° – 45°, (Left) 0° – 31°

Voltage (by areas)*

230 V, 240 V

Power Input* 1520 W

No-Load Speed 4000 /min

Machine Dimensions (Width × Depth × Height) 655 mm × 890 mm × 724 mm

Weight (Net) 27 kg

Laser Marker

Maximum output Po<0.4 mW Class 1M Laser Product

(Iambda) 650 nm

Laser medium Laser Diode

* Be sure to check the nameplate on product as it is subject to change by areas.

STANDARD ACCESSORIES

○ 305 mm TCT Saw blade (mounted on tool) ...................1

○ Dust bag .......................................................................1

○ 17 mm Box wrench .......................................................1

○ Vise Assembly ..............................................................1

○ Holder ...........................................................................1

○ Side Handle (mounted on tool) .....................................1

○ Sub Fence (mounted on tool) ........................................1

○ Washer (C) (Only For Australia) ....................................1

Standard accessories are subject to change without notice.

APPLICATION

Cutting various types of aluminium sash and wood.

PRIOR TO OPERATION

CAUTION

Make all necessary adjustments before inserting the

plug in the power source.

1. Power source

Ensure that the power source to be utilized conforms

to the power requirements specifi ed on the product

nameplate.

Do not use with direct current, or transformers such as

boosters. Doing so may result in damage or accidents.

2. Power switch

Ensure that the power switch is in the OFF position. If the

plug is connected to a receptacle while the trigger switch

is in the ON position, the power tool will start operating

immediately, inviting serious accident.

3. Extention cord

When the work area is removed from the power source,

use an extension cord of suffi cient thickness and rated

capacity. The extension cord should be kept as short as

practicable.

4. Remove all packing materials attached or

connected to the tool before attempting to operate

it.

5. Releasing the locking pin (Fig. 3)

When the power tool is prepared for shipping, its main

parts are secured by a locking pin.

Move the handle slightly so that the locking pin can be

disengaged.

During transport, lock the locking pin into the gear case.

6. Attach the dust bag to the main unit (Fig. 1)

7. Installation (Fig. 4)

Ensure that the machine is always fi xed to bench.

Attach the power tool to a level, horizontal work bench.

Select 8 mm diameter bolts suitable in length for the

thickness of the work bench.

Bolt length should be at least 40 mm plus the thickness

of the work bench.

For example, use 8 mm × 65 mm bolts for a 25 mm thick

work bench.

0000BookC12RSH2.indb120000BookC12RSH2.indb12 2016/03/1015:56:562016/03/1015:56:56

Loading...

Loading...