18

English

(1) Right angle cutting

Loosen the three 5 mm machine screws, then secure the left side table insert and

temporarily tighten the 5 mm machine screws of both ends. Then fi x a workpiece

(about 7-7/8" (200 mm) wide) with the vise assembly and cut it off . After aligning the

cutting surface with the edge of the table insert, securely tighten the 5 mm machine

screws of both ends. Remove the workpiece and securely tighten the 5 mm center

machine screw. Adjust the right hand table insert in the same way.

(2) Left and right bevel angle cutting

Adjust the table insert in the manner shown in Fig. 8-b and Fig. 8-c following the same

procedure for right angle cutting.

CAUTION: After adjusting the table insert for right angle cutting, the

table insert will be cut to some extent if it is used for bevel

angle cutting.

When bevel cutting operation is required, adjust the table

insert for bevel angle cutting.

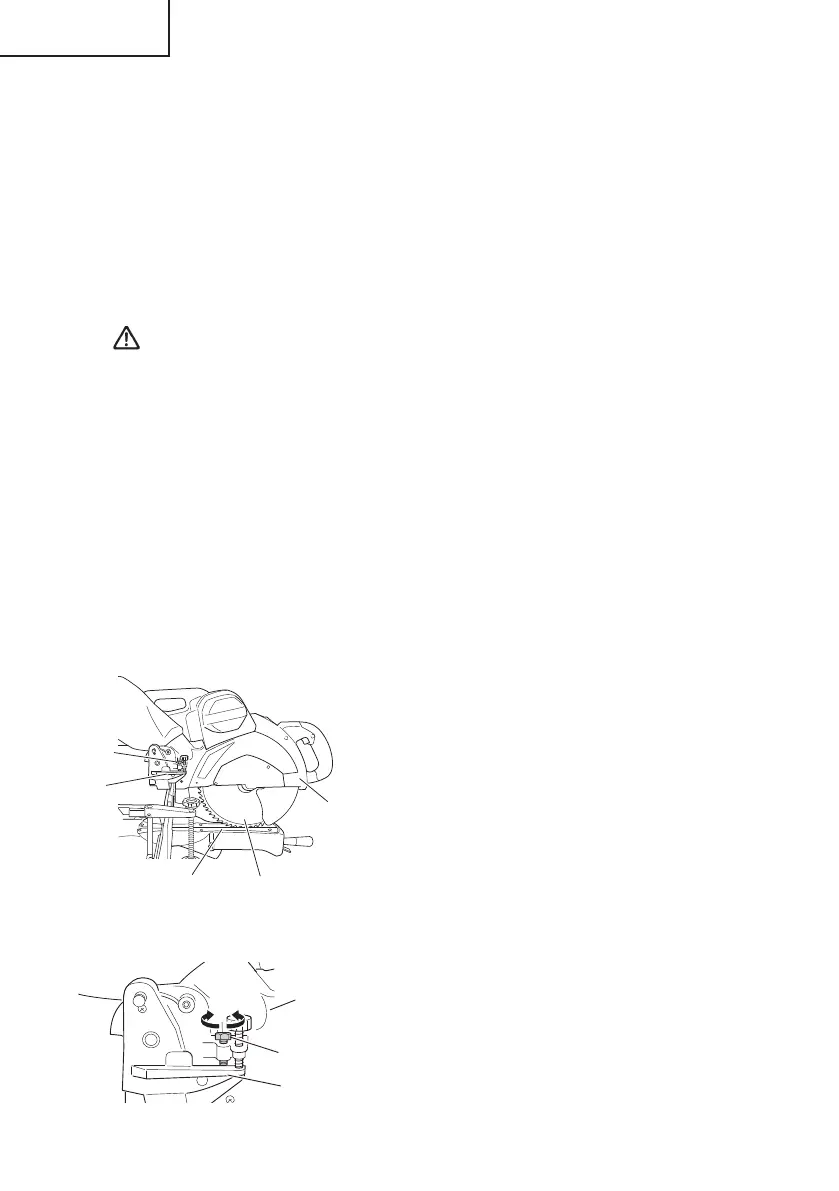

2. Checking the saw blade lower limit position

Check that the saw blade can be lowered 23/64" to 7/16" (9 mm to 11 mm) below the table

insert as shown in Fig. 9-a.

When you replace a saw blade with a new one, adjust the lower limit position so that the saw

blade will not cut the turntable or complete cutting cannot be done.

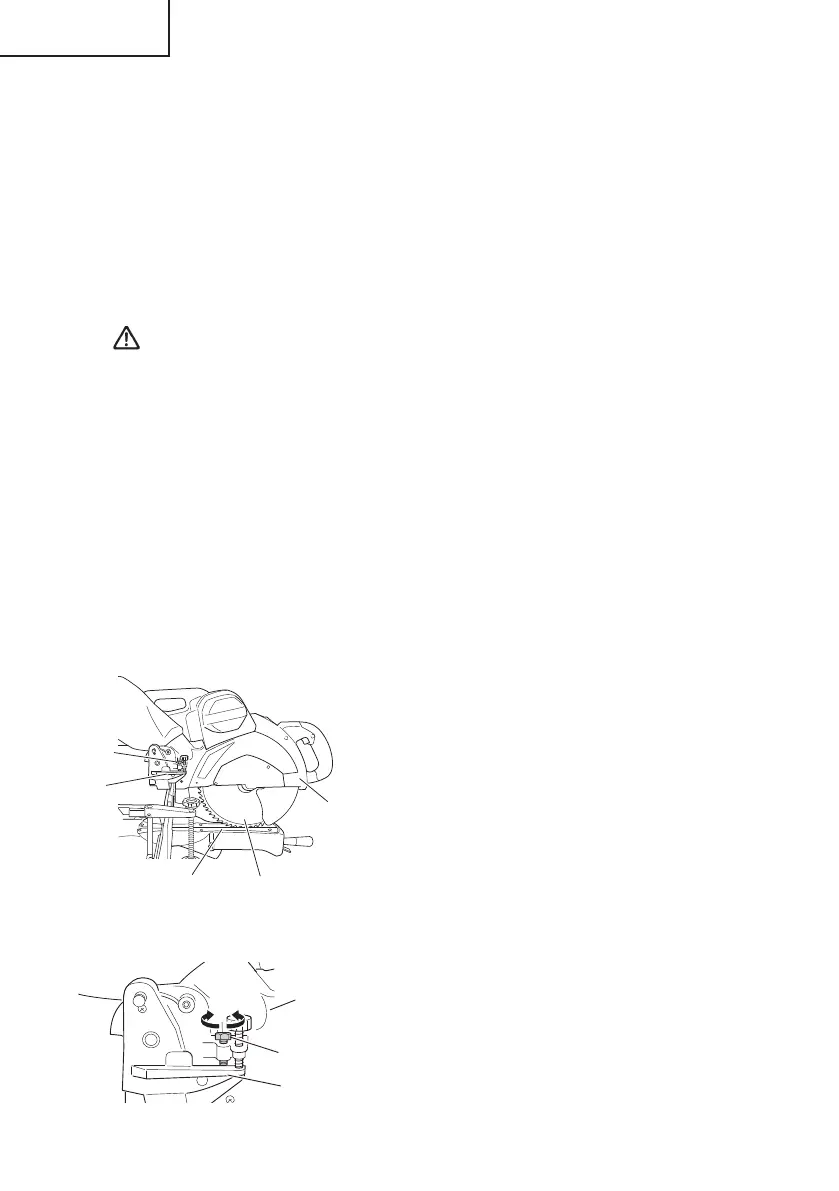

To adjust the lower limit position of the saw blade, follow the procedure (1) indicated below.

(Fig. 9-b)

Furthermore, when changing the position of a 8 mm depth adjustment bolt that serves as a

lower limit position stopper of the saw blade.

(1) Turn the 8 mm depth adjustment bolt,

change the height where the bolt head and

the hinge contacts, and adjust the lower

limit position of the saw blade.

NOTE: Confi rm that the saw blade is

adjusted so that it will not cut into

the turntable.

Gear case

8 mm depth

adjustment

bolt

Saw blade

Turntable

Fig. 9-a

Hinge

Fig. 9-b

8 mm depth

adjustment bolt

Turn

Hinge

Gear case

0000BookC12RSH2.indb180000BookC12RSH2.indb18 2016/03/0118:07:312016/03/0118:07:31

Loading...

Loading...