32

English

Type of Crown

Molding

To process crown molding at

positions 1 and 4 in Fig. 36.

To process crown molding at

positions 2 and 3 in Fig. 36.

Miter Angle

Setting

Bevel Angle

Setting

Miter Angle

Setting

Bevel Angle

Setting

45° Type

right 35.3°

(

mark)

left 30°

( mark)

left 35.3°

( mark)

left 30°

( mark)

38° Type

right 31.6°

(

mark)

left 33.9°

( mark)

left 31.6°

( mark)

left 33.9°

( mark)

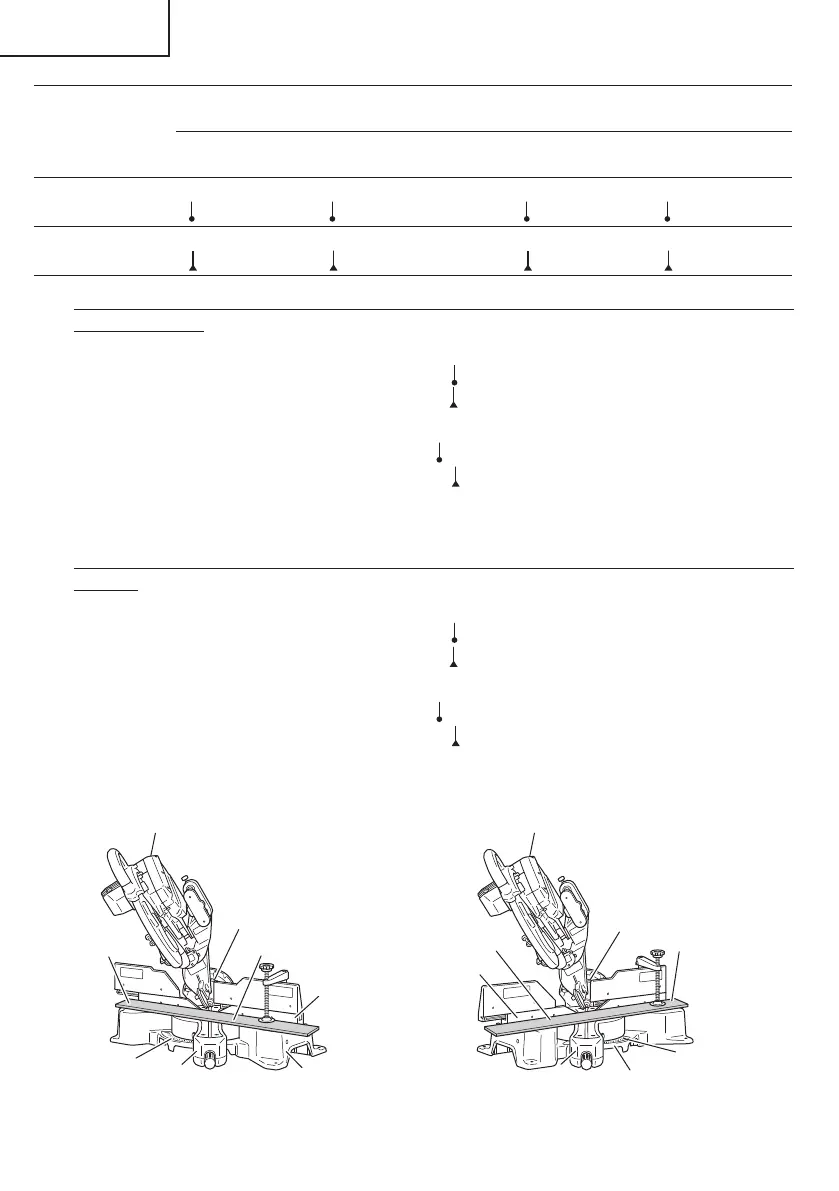

(1) Setting to cut crown moldings at positions 1 and 4 in Fig. 36 (see Fig. 37; tilt the motor

head to the left):

1 Turn the turntable to the right and set the Miter Angle as follows:

* For 45° type crown moldings: 35.3° (

mark)

* For 38° type crown moldings: 31.6° (

mark)

2 Tilt the motor head to the left and set the Bevel Angle as follows:

* For 45° type crown moldings: 30° ( mark)

* For 38° type crown moldings: 33.9° (

mark)

3 Position the crown molding so that the upper surface (Ⓐ in Fig. 35) contacts the fence

as indicated in Fig. 39.

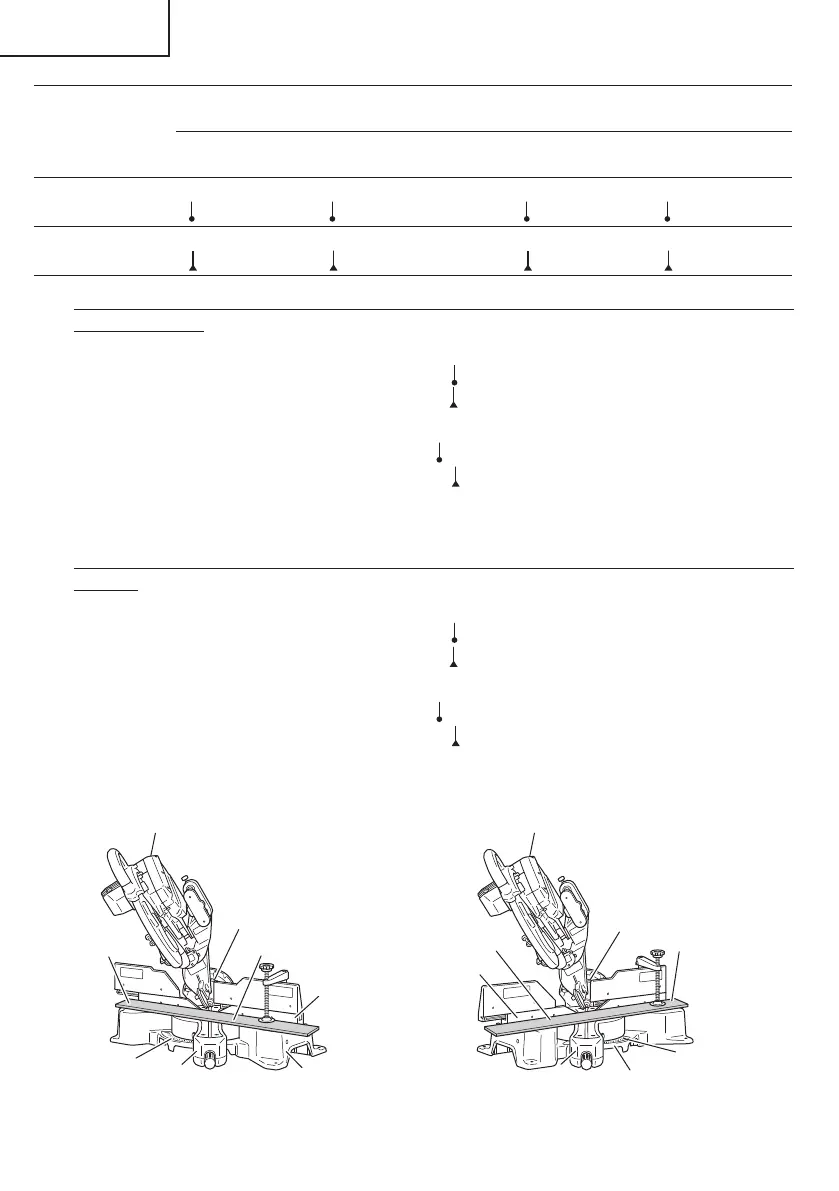

(2) Setting to cut crown moldings at positions 2 and 3 in Fig. 36 (see Fig. 38; tilt the head to

the left):

1 Turn the turntable to the left and set the Miter Angle as follows:

* For 45° type crown moldings: 35.3° (

mark)

* For 38° type crown moldings: 31.6° (

mark)

2 Tilt the head to the left and set the Bevel Angle as follows:

* For 45° type crown moldings: 30° ( mark)

* For 38° type crown moldings: 33.9° (

mark)

3 Position the crown molding so that the lower surface (Ⓑ in Fig. 35) contacts the fence

as in Fig. 40.

Bevel angle scale

Fence (A)

Miter angle

scale

Turntable

Head

Base

Bevel angle scale

Base

Miter angle scale

Turntable

Head

Fence (B)

Fig. 37 Fig. 38

1

4

2

3

0000BookC12RSH2.indb320000BookC12RSH2.indb32 2016/03/0118:07:362016/03/0118:07:36

Loading...

Loading...