-19-

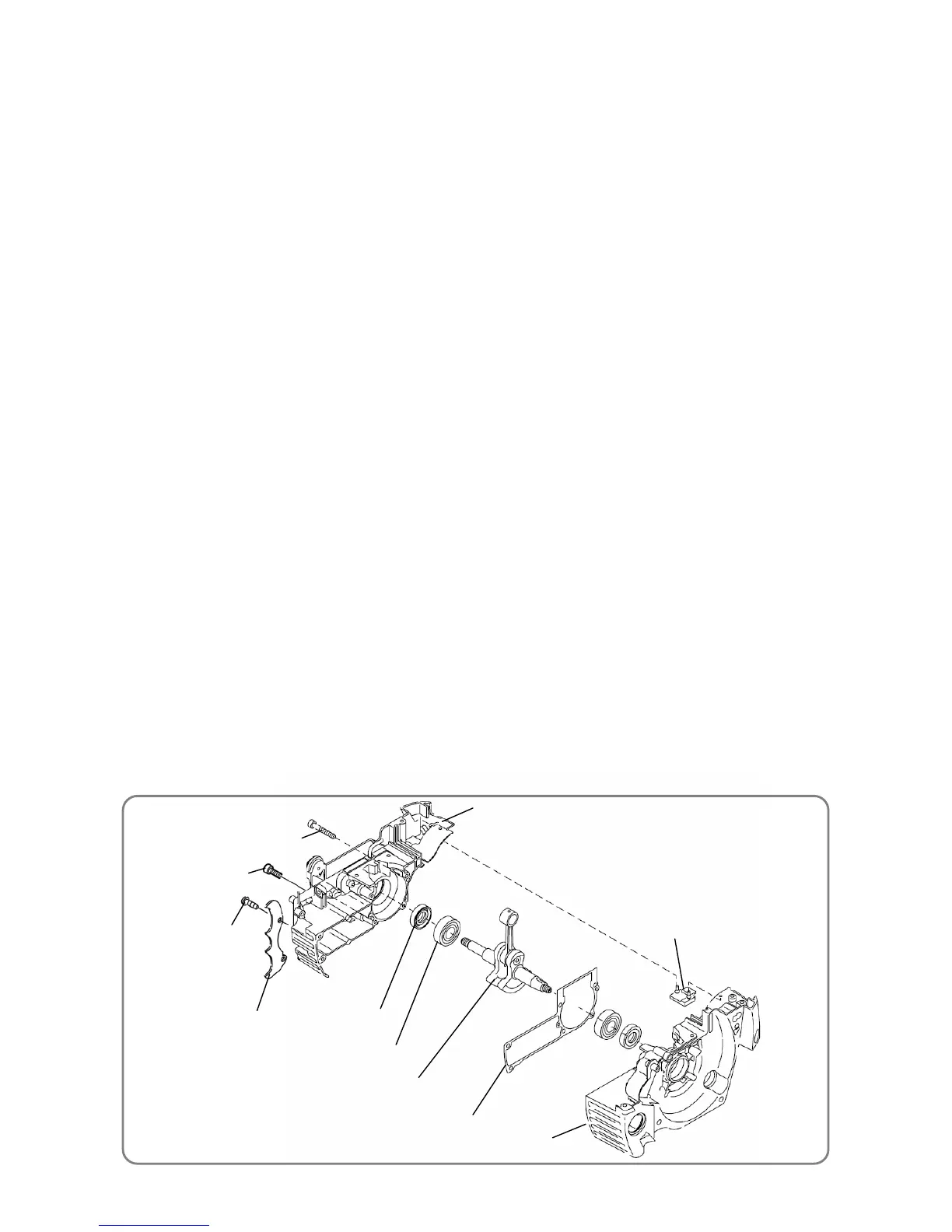

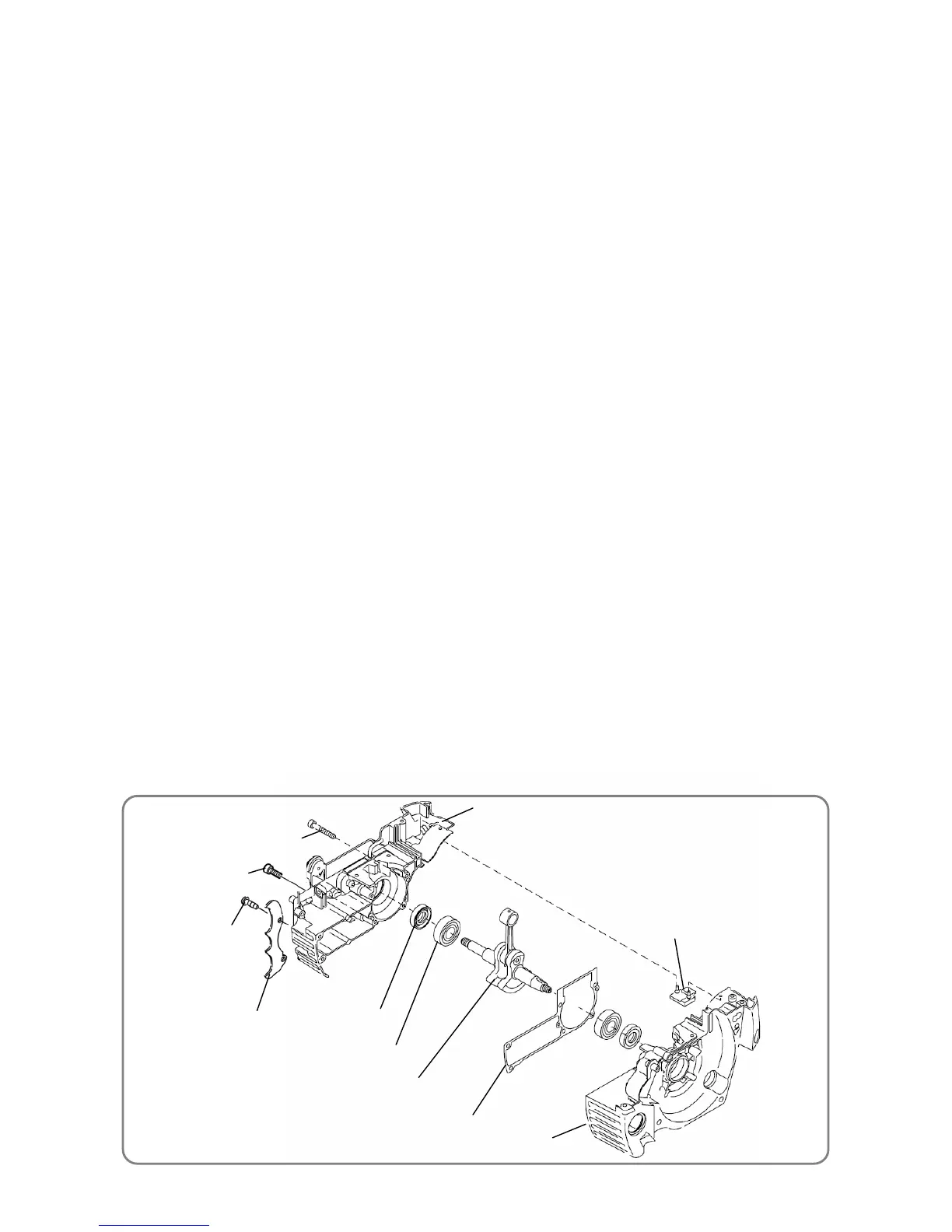

Engine Case (B) Ass’y [80]

Oil Seal [81]

Ball Bearing 6202C3 [82]

Crank Shaft [83]

Crank Case Packing (C51) [84]

Engine Case (A) Ass’y [87]

Rear Damper (C51) [88]

Seal Lock Hex.

Socket Hd. Bolt

M5 [32]

Seal Lock Hex.

Socket Hd. Bolt

M5 x 45 [35]

Seal Lock

Screw

M5 x 12 [33]

Spike [34]

Ɣ Engine case

12. Disassembly and reassembly of the engine case

[Tools required]

Ɣ Hex. bar wrench (5 mm)

Ɣ Phillips screwdriver

Ɣ Long-nose pliers

(1) Disassembly

Ɣ Use long-nose pliers to pull out the Rear Damper (C51) [88].

Ɣ Use a Phillips screwdriver to remove the two Seal Lock Screws M5 x 12

[33]

, and then remove the Spike

[34]

.

CAUTION: The threads of the Seal Lock Screws M5 x 12 [33] may be easily broken. Therefore, do not

tighten the screws too much.

Ɣ Use a 5-mm hex. bar wrench to remove the four Seal Lock Hex. Socket Hd. Bolts M5 [32] and two Seal

Lock Hex. Socket Hd. Bolts M5 x 45 [35]. Then remove the Engine Case (A) Ass’y [87], Engine Case

(B) Ass’y [80], and Crank Shaft [83].

Ɣ Remove Ball Bearing 6202C3 [82] and the Oil Seal [81] by pushing it out on the Oil Seal [81] side.

(2) Reassembly

Reassembly can be conducted by reversing the disassembly procedure. However, special attention

should be given to the following items.

Ɣ Do not reuse the Oil Seal [81] and Ball Bearing 6202C3 [82] removed from the Engine Case (A) Ass’y

[87] and Engine Case (B) Ass’y [80].

Ɣ Do not reuse the Crank Case Packing (C51) [84].

Ɣ Do not reuse the Seal Lock Hex. Socket Hd. Bolts M5

[32]

and Seal Lock Hex. Socket Hd. Bolts M5 x 45

[35]

.

Ɣ Apply 50 to 100 mg of Piloknock Universal No. 0 of JX Nippon Oil & Energy between the lips of the Oil

Seal [81].

Ɣ Carefully clean the Crank Shaft [83] by using gasoline before mounting.

Ɣ Degrease the screw holes of the Engine Case (A) Ass’y [87] and Engine Case (B) Ass’y [80] before

mounting. Do not get the Fuel Pipe [119] caught between the Engine Case (A) Ass’y [87] and Engine

Case (B) Ass’y [80] when mounting.

Ɣ Check the hole position of the Crank Case Packing (C51) [84] and mount it without misalignment.

(When mating the Engine Case (A) Ass’y [87] and Engine Case (B) Ass’y [80], confirm that the Crank

Case Packing (C51) [84] is properly mounted along the circumference of the engine case.)

Ɣ Cut off the protrusion of the Crank Case Packing (C51) [84] at the mating surface of the Cylinder [73]

after mounting.

CAUTION: Do not break the Crank Case Packing (C51) [84] when cutting it.

Loading...

Loading...