English

— 9 —

2. Location

WARNING: In order to avoid damaging this

compressor, do not incline this

compressor transversally or

longitudinally more than 10°.

Place this compressor at least 4 inches (10 cm) away

from obstacles that may prevent proper ventilation. Do

not place this compressor in an area:

- where there is evidence of oil or gas leaks.

- where fl ammable gas vapors or materials may be

present.

- where air temperatures fall below 32°F (0

°C) or

exceed 95°F (35

°C).

- where extremely dirty air or water could be drawn into

this compressor.

CAUTION:

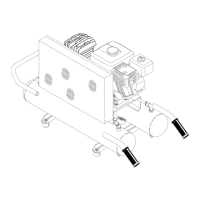

When operating or storing the compressor,

set 4 rubber bumpers downward on the

fl oor (Refer to Fig. 1).

Excessive vibration is a major cause of

premature compressor failure.

Always maintain the rubber bumper located

beneath tank.

3. Gasoline engine

A) Review page 6. 27 before fueling.

WARNING:

Do not allow the engine or muffl er

to come in contact with fl ammable

vapors, combustible dust, gases

or other combustible materials. A

spark may cause a fi re. Do not place

this compressor in an area where

fl ammable gas vapors may be present.

B) Read the engine manual accompanying this

compressor for correct engine start-up maintenance

procedures.

C) Read and understand the safety labels located on

this compressor.

D) A minimum of 85 octane fuel is recommended

for use with this compressor. Do not mix oil with

gasoline.

E) Use of clean, fresh, lead free gasoline should be

used. Do not use gasoline containing methanol or

alcohol.

F) Check the engine oil level before starting (See

engine manual).

G) Fill the fuel tank according to the engine manual

instructions.

WARNING:

Follow all fueling instructions in

operator’s manual. Gasoline is

extremely fl ammable, and gasoline

vapor can explode. Do not refuel

fuel tank while this compressor

is running or hot. Never smoke

near gasoline, and keep other

fl ames and sparks away. Allow this

compressor and engine to cool

down before refueling. Do not refuel

indoors or in a poorly ventilated

area. Do not fi ll fuel tank to point of

overfl owing. Always refuel slowly

to avoid the possibility of spilled

fuel which may cause a fi re. Do not

operate this compressor if gasoline

is spilled. Wipe this compressor

clean and move it away from the

spill. Avoid creating any ignition

until the gasoline has evaporated.

Allow approximately 1/4” (6 mm)

of tank space for fuel expansion.

Always store fuel away from this

compressor while it is running or

hot. Always store gasoline in an

approved container.

H) Refer to the engine manual for all necessary

maintenance and adjustments.

WARNING:

Do not operate this compressor in an

enclosed area. Use this compressor

only in well ventilated areas. The

exhaust from the engine contains

carbon monoxide, a poisonous,

odorless and invisible gas. Breathing

the gas can cause serious injury,

illness and possible death. Avoid

inhalation of exhaust gas. Never

run the engine in a closed garage or

confi ned area.

4. Air coupler installation

Screw in the air coupler to the joint (Refer to Fig.1 and

Fig.5). The screw size of the joint is 3/8”. Use an air

coupler which has the same screw size.

5. Pre-start checklist

A) Make sure the engine switch is in the “OFF” position.

B) Remove any moisture in this compressor air tank.

Gradually open the drain cock and discharge the

drain. Close tightly when drained.

C)

Make sure the safety valve is working correctly (refer

to Fig.1). The safety valve is designed to prevent

system failures by relieving pressure from the system

when this compressed air reaches a predetermined

level. The safety valve is preset by the manufacturer

and must not be modifi ed in any way.

Before starting the compressor, pull the ring on

the safety valve to make sure that the safety

valve operates smoothly. (Fig. 7) Do not use the

compressor if the safety valve is stuck or does not

operate smoothly. Have the defective safety valve

replaced by a Hitachi authorized service center.

Safety valve

Fig. 7

WARNING: Drain tank to release air pressure

before pull the ring on the safety

valve.

000BookEC2610Elowes.indb9000BookEC2610Elowes.indb9 2018/03/0910:24:512018/03/0910:24:51

Loading...

Loading...