Refrigerant piping & refrigerant charge

23

PMML0317A rev.1 - 11/2013

ENGLISH

4 Correct position of Triple Branch Pipe (Standard series only).

• Install the header horizontally

Sample: Triple Branch pipe

Gas piping

Liquid piping

13.4.3 Brazing work

C A U T I O N

• Use nitrogen gas for blowing during pipe brazing. If oxygen,

acetylene or uorocarbon gas is used, it will cause an explo-

sion or poisonous gas.

• A lot of oxidation lm will occur inside of tubes if no nitrogen

gas blowing is performed during brazing work. This lm will

be ecked off after operation and will circulate in the cycle,

resulting in clogged expansion valves, etc. This will cause bad

inuence to the compressor.

• Use a reducer valve when nitrogen gas blowing is performed

during brazing. The gas pressure should be maintained within

0.03 to 0.05 Mpa. If a excessively high pressure is applied to

a pipe, it will cause an explosion.

13.4.4 Refrigerant charge

C A U T I O N

• Do not charge OXYGEN, ACETYLENE, or other ammable

and poisonous gases into the refrigerant because an explo-

sion can occur. It is recommended that oxygen free nitrogen

be charged for these types of tests cycle when performing

a leakage test or an airtight test. These types of gases are

extremely dangerous,

• Insulate the unions and are-nuts at the piping connection

part completely.

• Insulate the liquid piping completely to avoid a decrease of

performance; if not, it will cause sweating on the surface of

the pipe.

• Charge refrigerant correctly. Overcharging or insufcient

charging could cause a compressor failure.

• Check for refrigerant leakage in detail. If a large refrigerant

leakage occurred, it would cause difculty with breathing or

harmful gases would occur if a re were being used in the

room.

• If the are nut is tigthened too hard, the are nut may crack

after a long time and cause refrigerant leakage.

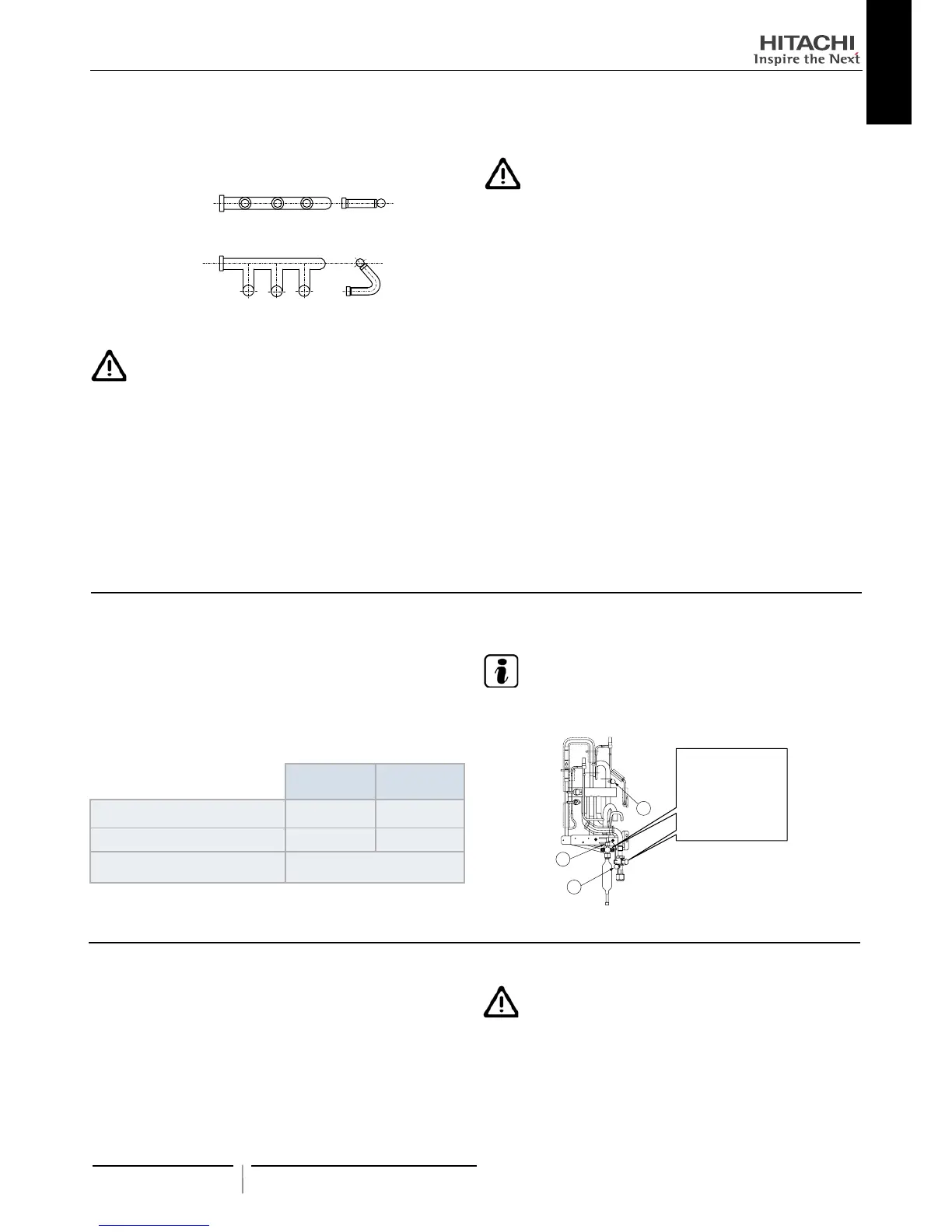

13.6 REFRIGERANT CHARGING QUANTITY

When the pressure is measured, use the check joint of gas stop

valve (A), and use the check joint of liquid piping (B) in the gure

below.

At that time, connect the pressure gauge according to the follow-

ing table because of high pressure side and low pressure side

changes by operation mode.

Cooling

Operation

Heating

Operation

Check Joint for Gas Stop Valve “A” Low Pressure High Pressure

Check Joint for Piping “B” High Pressure Low Pressure

Check Joint for Liquid Stop Valve “C”

Exclussive for Vacuum Pump

and Refrigerant Charge

N O T E

Be careful that refrigerant and oil do not splash to the electrical

parts at removing the charge hoses.

C

B

A

The gas stayed at O-ring

screw part is o p e ned

and may mak e sou n d

when removing the cap.

However, it is n ot gas

leakage.

13.5 CAUTION OF THE PRESSURE BY CHECK JOINT

Outdoor Units has been charged with refrigerant for 30m of actual

piping length. An additional refrigerant charged is required in sys-

tems with actual piping length longer than 30m.

1 Determine an additional refrigerant quantity according to the

following procedure, and charge it into the system.

2 Record the additional refrigerant quantity to facilitate service

activities thereafter.

C A U T I O N

• When charging refrigerant accurately measure refrigerant to

be charged.

• Overcharging or undercharging of refrigerant can cause com-

pressor trouble

• In case of actual piping length less than 5 m, consult your

distributor.

Loading...

Loading...