7

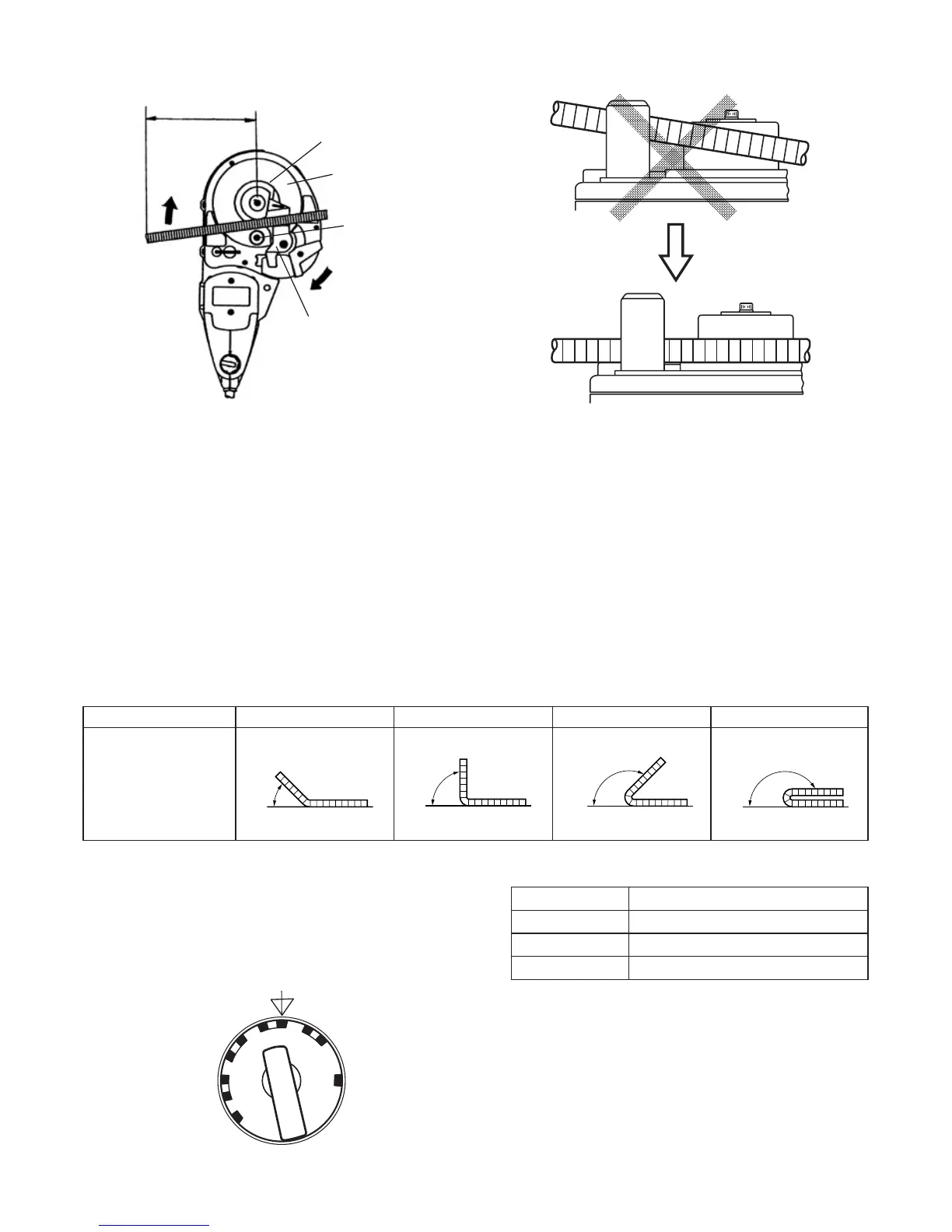

Fig. 10

䡬 When bending multiple rebars at one time, some may

come off the bending roller and guide, etc., and

therefore exercise caution and set them horizontally.

䡬 If you bend the rebar with a large angle while placing

your hand onto it, there is a fear of getting your hand

caught in by the fold-back reaction of the rebar. Never

place your hand onto the position where the rebar

may fold back.

䡬 Do not bend more than 50 rebars in one session as

this will overload the motor, and may cause it to burn

out.

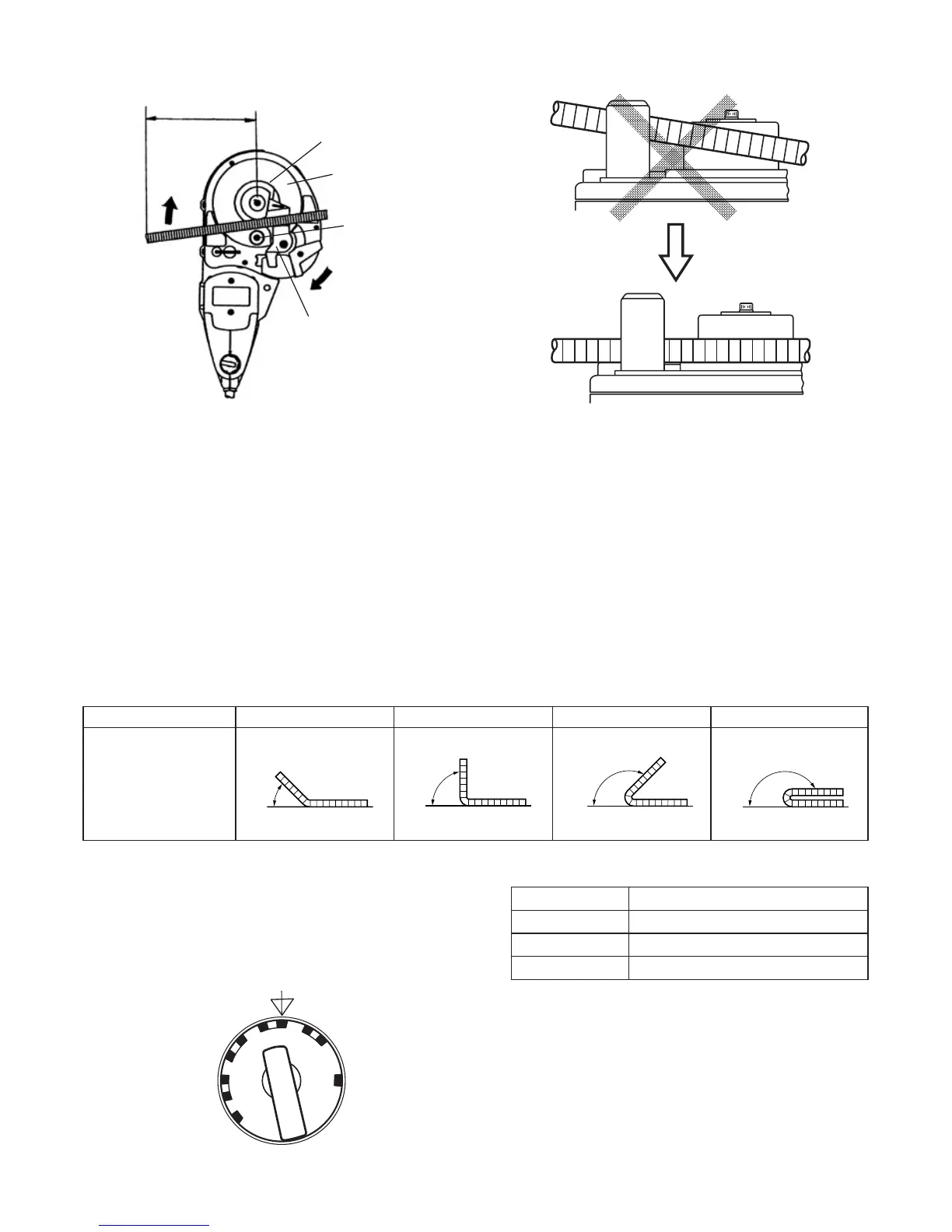

1. Setting bending angles by setting dial

The bar can be bent according to the angles indicated

on the setting dial, as shown in Fig. 11.

In bending the rebar of 10 mm, 12 mm, and 16 mm

diameters, a difference takes place in the bending angle

even in the same dial position depending upon the

difference of rebar’s thickness. Slightly change a

position of the setting dial depending upon the rebar’s

diameter even with the same bending angle as illustrated

in the top diagram on the left column. (Fig. 12)

Fig. 12

Size of rebar Colors of indicated marks

ø10 mm White

ø12 mm Red

ø16 mm Yellow

NOTE:

Even at the same dial setting position, the bending

angle can sometimes differ if the diameter or hardness

of the rebar is different. Use the angle marks merely

as a rough guideline.

2. Ordinary bending

(1) Set the unit in the position with the turntable up as

shown in Fig. 13.

䡬 Place the rebar on the center plate and set it so that it

is horizontal with the turntable surface.

If the side that is to be bent is set inclined upward, the

rebar can come loose from the bending roller while

bending causing it to fly off. (Fig. 10)

Fig. 9

Center plate

Stopper

200 mm

Bending roller

Turn table

Fig. 11

Condition of rebar

Dial indication 45° 90° 135° 180°

180°135°90°45°

0˚

RETURN

CUT

45˚

90˚

135˚

180˚

Loading...

Loading...