32

Ill.

ENGINE

7.

Remove the crankshaft from

Lite

upper crankcase.

lnspeclion

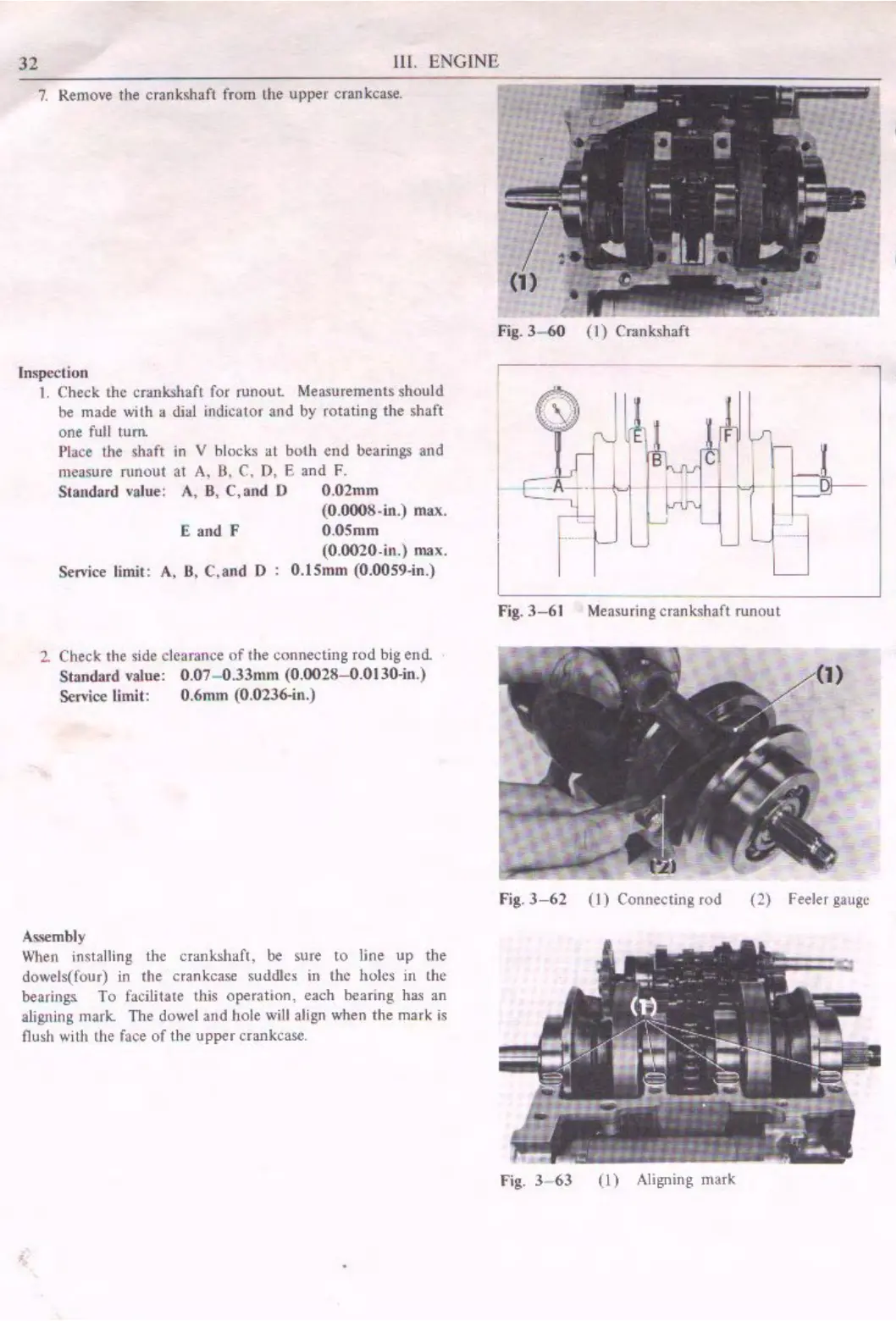

I. Check the crankshaft for runouL Measurements

should

be made with a dial indicator

and

by

rotating the shaft

one

full

tum

Place the shaft in V hlocks

al

both

end

bearillll,S

and

measure

run

out at

A,

B.

C.

D,

F..

and

F.

Standard value: A,

B,

C, and O

0.02mm

(0.0008-in.)

max.

E and F 0.05mm

(0.0020-in.)

max.

Service limit:

A,

B,

C.and D

0.15mm

(0.00S9-in.)

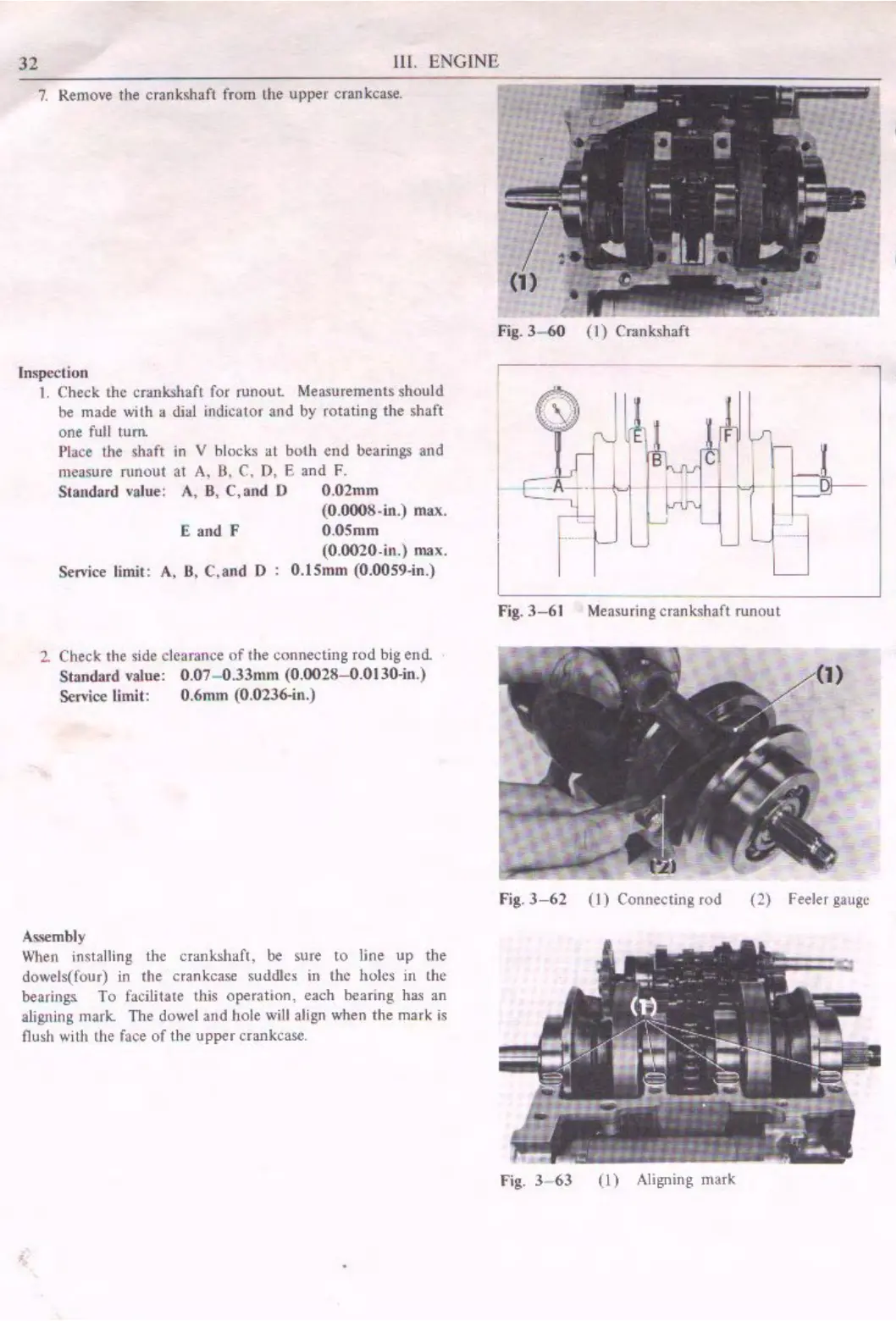

2 Check the side clearance

of

Che

connecting rod big end.

Standard value: 0.07- 0.33mm

(0.0028-0.0130-in.)

Service limit:

0.6mm

(0.0236-in.)

A&5emhly

When installing the crankshafl,

be

sure

to

line

up

the

dowels(four) ill the crankcase sutlillcs in tt,e holes in the

bearings

To

facilitate this operation, each bearing has an

aligning mark. The dowel and hole

will

align when the mark is

0ush with the face

of

the

upper

crankcase.

Fig.

3-60

(I)

Cmnkshaft

,

..

Fig

.

3-61

Measuring crankshaft runout

Fig.

3-62

(I)

Connecting rod

(2)

Feeler

gauge

Fig

. 3-

63

(I)

Aligning mark

Loading...

Loading...