HW-500-003 2 I56-3934-002R

FIGURE 1: MOUNTING OF DETECTOR

S0121-00

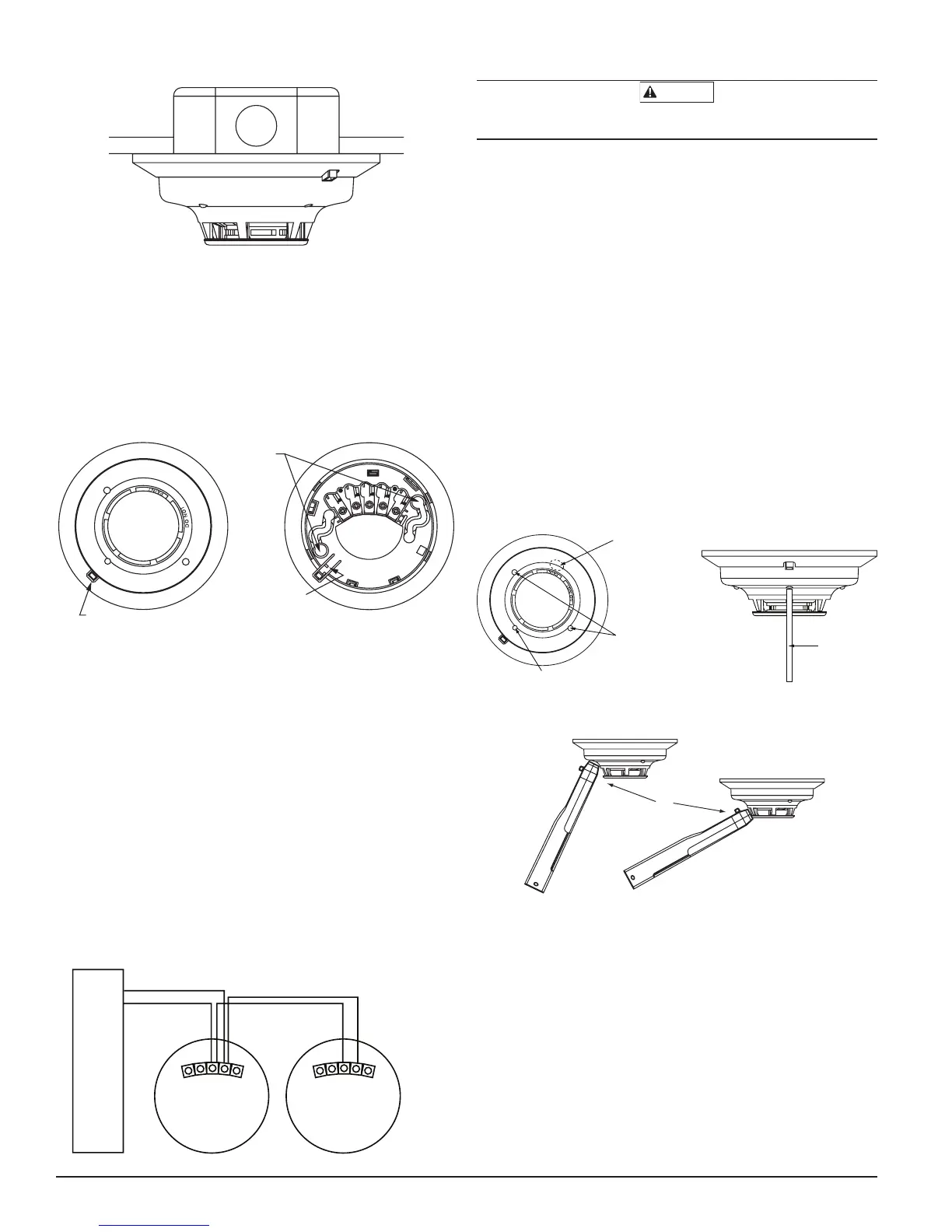

TAMPER-RESISTANT FEATURE

The 5193SD/SDT detector includes a tamper-resistant feature that prevents

removal from the mounting base without the use of a tool. To engage the tam-

per-resistant feature, cut the small plastic tab located on the mounting base

(Figure 2), and then install the detector. To remove the detector from the base

once it has been made tamper resistant, use a small screwdriver to depress the

square tamper release tab, located on the skirt of the mounting base, and turn

the detector counterclockwise.

FIGURE 2: TAMPER-RESISTANT FEATURE

SNAP OFF TAB

FOR TAMPER LOCK

TAMPER

RELEASE TAB

DIRECT MOUNT

HOLES

S0226-00

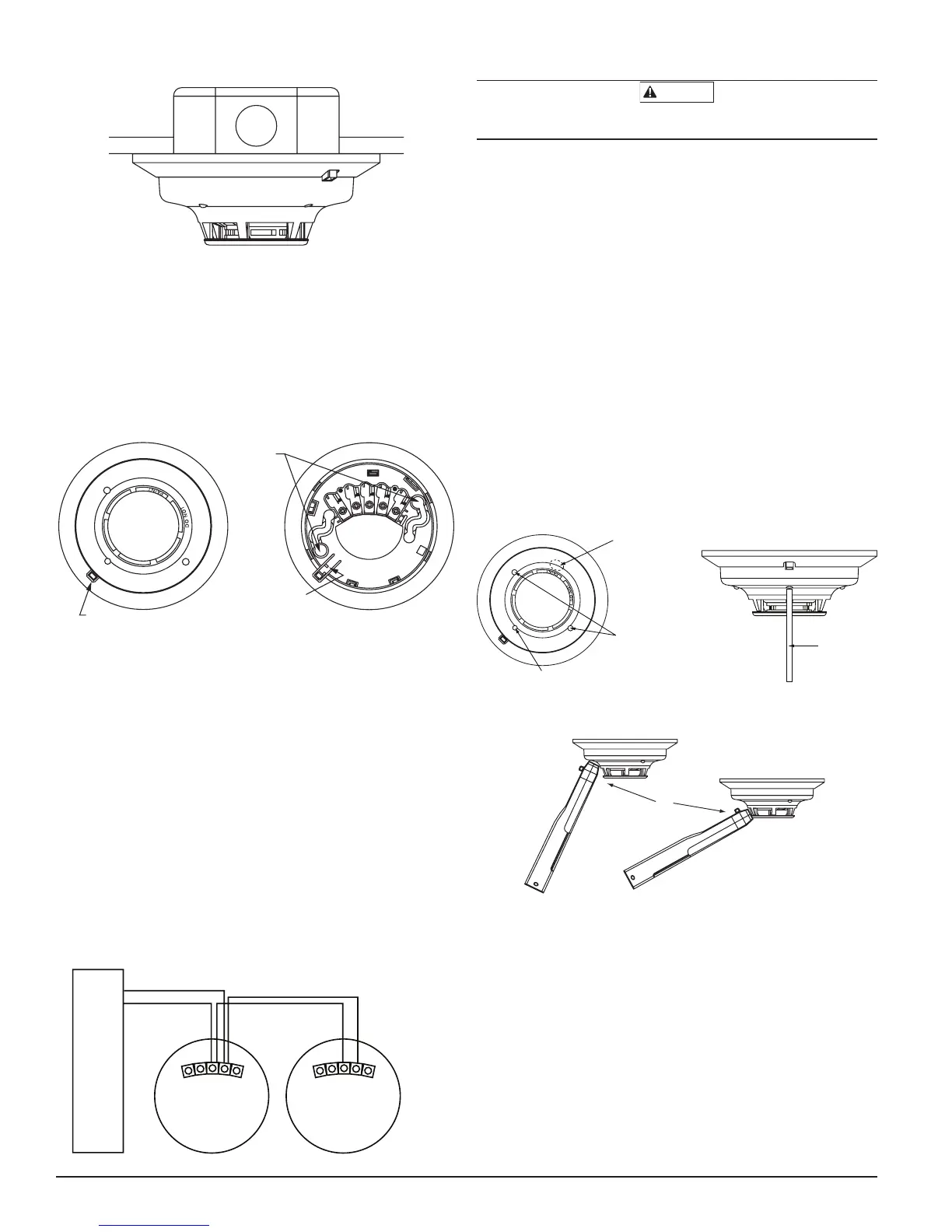

WIRING DIAGRAM

FIGURE 3: WIRING DIAGRAM, 5193SD/SDT

S0133-01

INSTALLATION

Remove power from alarm control unit or initiating device circuits before in-

stalling detectors.

NOTE:

To install units so that corresponding LEDs are lined up, refer to the

“Green LED” indicator on the base.

1. Wire the mounting base screw terminals per Figure 3.

2. Place detector on the base and rotate clockwise. The detector will drop

into the base and lock into place with a “click”.

3. After all detectors have been installed, apply power to the alarm control

unit or initiating device circuits.

4. Test each detector as described in

Testing.

5. Reset all the detectors at the system control panel.

6. Notify the proper authorities that the system is in operation.

TESTING

Detectors must be tested after installation and following maintenance.

NOTE:

Before testing, notify the proper authorities that maintenance is being

performed and the system will be temporarily out of service. Disable the zone

or system undergoing maintenance to prevent any unwanted alarms.

Ensure proper wiring and power is applied.

After power up, allow 50

seconds for the detector to stabilize before testing.

TEST 5193SD/SDT DETECTOR AS FOLLOWS:

A.Test Switch

S0135-01

FIGURE 4: RECESSED TEST SWITCH OPENING AND SENS-RDR POSITION

PUSH RECESSED

SWITCH WITH A

0.18w MAX.

DIAMETER TOOL

LED

RECESSED TEST SWITCH

POSITION SENS-RDR

AT AN ANGLE ON THE

OVAL AREA OR AT THE

CHAMBER OPENING

BY THE WORD “PAINT”

FIGURE 5: POSITION OF READER

S0227-00

1. An opening for the recessed test switch is located on the detector hous-

ing (See Figure 4).

2. Insert a small screwdriver or allen wrench (0.18˝ max.) into the test

switch opening; push and hold.

3. If the detector is within the listed sensitivity limits, the detector’s red

LED should light within five seconds. An alarm should be annunciated at

the system’s control or console within 5 seconds.

B. Smoke Entry Test

Canned aerosol simulated smoke (canned smoke agent) may be used for

smoke entry testing of the smoke detector. Tested and approved aerosol

smoke products are the Smoke Detector Tester model 25S available from

Home Safeguard Industries and Chekkit Smoke Detector Tester mod-

els CHEK02 and CHEK06 available from SDi. When used properly, the

canned smoke agent will cause the smoke detector to go into alarm.

WIRING INSTALLATION GUIDELINES

All wiring must be installed in compliance with the National Electrical Code,

applicable state and local codes, and any special requirements of the local

Authority Having Jurisdiction.

Proper wire gauges should be used. The conductors used to connect smoke

detectors to the alarm control panel and accessory devices should be color-

coded to reduce the likelihood of wiring errors. Improper connections can

prevent a system from responding properly in the event of a fire.

The screw terminals in the mounting base will accept 14–22 gauge wire. For

best system performance, all wiring should be installed in separate grounded

conduit; do not mix fire alarm system wiring in the same conduit as any other

electrical wiring. Twisted pair may be used to provide additional protection

against extraneous electrical interference.

Wire connections are made by stripping approximately

1

/4-inch of insulation

from the end of the feed wire, inserting it into the proper base terminal, and

tightening the screw to secure the wire in place.

Loading...

Loading...