MINIPEEPER

®

ULTRAVIOLET FLAME DETECTORS

60-2026-16 6

Mounting a C7027A, C7927 or C7035A

Locate the Sight Pipe

The location of the sight pipe is the most critical part of the

installation. A black iron pipe is recommended. Do not use a

stainless steel or galvanized pipe because its internal surface

blackens with use as deposits from the combustion chamber

settle on it. Initially, its shiny internal surface reflects ultraviolet

radiation, which could result in a satisfactory flame signal, even

though the pipe may be improperly located. As it blackens, less

ultraviolet radiation is reflected and the flame signal may

become marginal.

Under optimum sighting conditions, the C7027A, C7927 and

C7035A Flame Detectors can detect most common gas and oil

combustion flames at a distance of six feet. The critical factors

in determining the flame-detector distance separation are the

optimized flame signal (current or voltage) and the flame

detector temperature. Other factors may be influential and are

associated with the specific installation. For minimum flame

signals, see Table 1 and for ambient operating temperatures,

refer to Specifications, page 2.

Use 1/2 in. pipe for a C7027 or C7927, and 1 in. pipe for

a C7035. Since no two situations are likely to be the same,

length and sighting angle of the pipe must be determined at the

time and place of installation. Generally, it is desirable

to have the sight pipe tilting downward to prevent soot or dirt

buildup.

If a C7027A or C7927A is to be used for a blast tube

installation, its location should be determined by the burner

manufacturer; contact the manufacturer before making any

modifications to the installation.

In locations where water is usually sprayed on the body of the

detector, use a C7035A. Internal threads in its base permit the

use of waterproof flexible conduit for this type of application.

Prepare Hole In Wall Of Combustion Chamber

Cut a hole of the proper diameter for the sight pipe in the wall

of the combustion chamber at the selected location. Flare the

hole to leave room for small adjustments of the sighting angle.

The taper of the hole should be about 1 in. for every 3 in.

(25 mm for every 76 mm) of wall thickness.

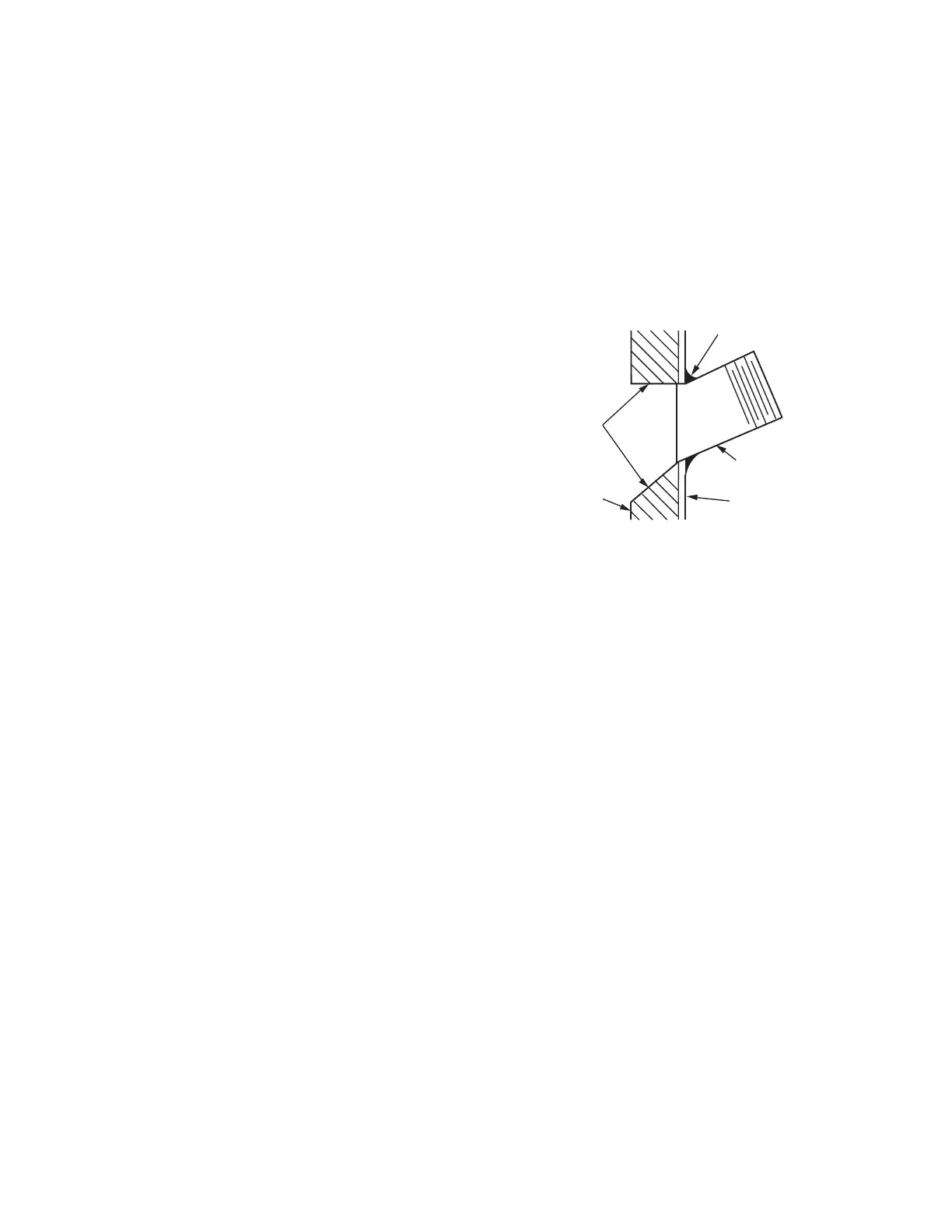

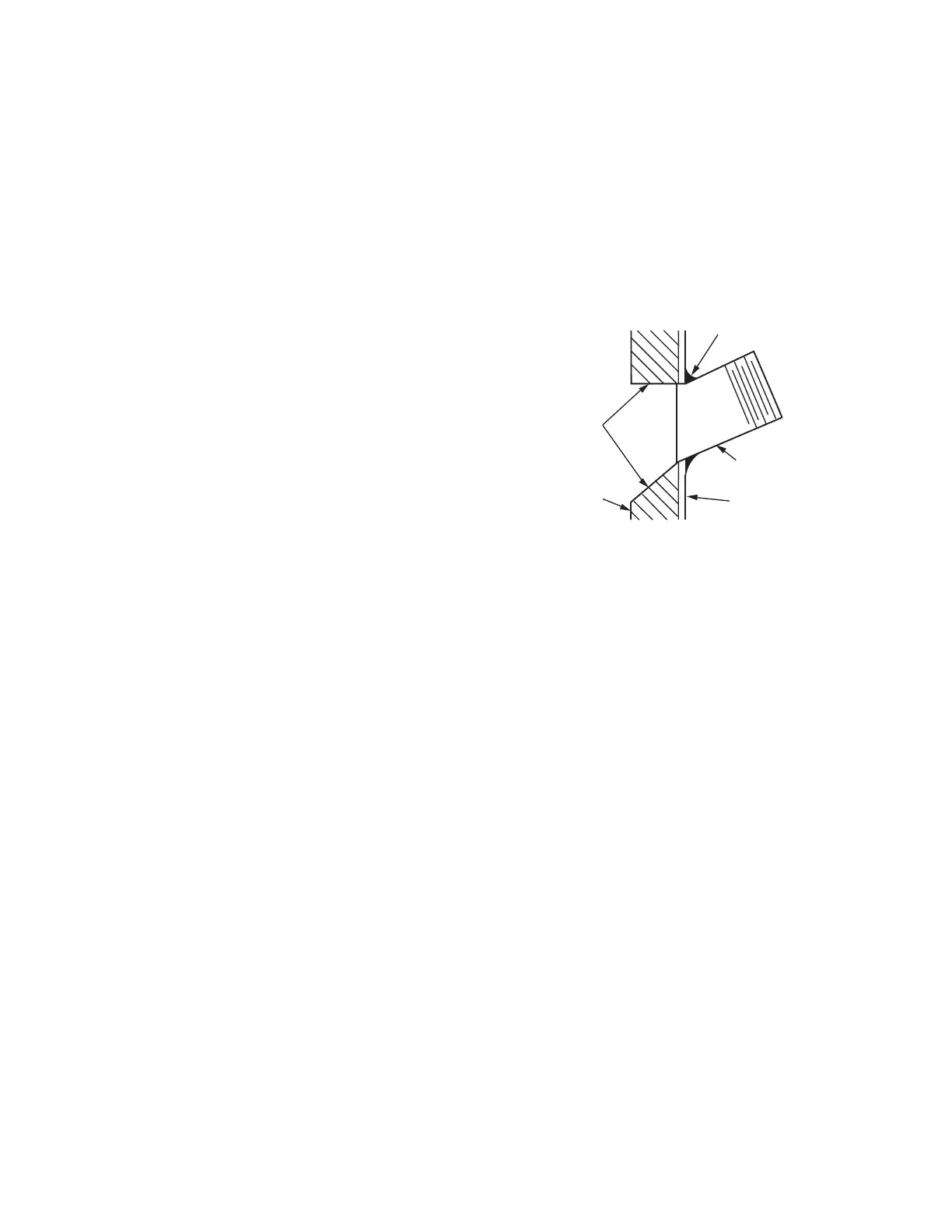

Mounting The Sight Pipe (Fig. 5)

Thread one end of the pipe to fit the mounting collar on the

detector. Cut the pipe to the desired length (as short as

practicable), and at an angle so it fits flush with the wall of the

combustion chamber. Tack-weld the pipe to the wall in a trial

position. Do not permanently weld the sight pipe in place until

after completing the Adjustments and Checkout beginning on

page 9.

NOTE: If you use a swivel mount (part no. 118367A) and you

are positive about the location and sighting angle, you

can permanently weld the pipe.

Fig. 5. Mounting sight pipe.

Sight Pipe Ventilation

It may be necessary to ventilate the sight pipe to cool the flame

detector or to clear the sight pipe of UV radiation absorbing

substances such as smoke, excessive moisture or, in some

instances, unburned fuel.

For a negative pressure combustion chamber, drilling a few

holes in the section of the sight pipe outside of the combustion

chamber will allow air at atmospheric pressure to flow through

the sight pipe into the chamber. A perforated pipe nipple

between the sight pipe and the detector can also be used

(see Fig. 6).

For a positive pressure combustion chamber, connect a supply

of pressurized air from the burner blower through the sight pipe

into the chamber. The supply air pressure must be greater than

the chamber pressure.

FLARED HOLE

REFRACTORY

M3019C

TEMPORARY

TACK WELD

BLACK IRON

SIGHT PIPE

BOILER

PLATE

Loading...

Loading...