MINIPEEPER

®

ULTRAVIOLET FLAME DETECTORS

9 60-2026-16

3. Avoid installation considerations that can influence

detector operation and maximum lead wire length, such

as:

a. Moisture.

b. Ignition interference.

c. High resistance connections—poor grounds.

d. Lead wire capacitance.

e. Voltage fluctuations.

f. Induced line transients.

g. Floating grounds—ground at some voltage above

earth ground.

h. No G wire—burner used as ground.

i. Detector output less than maximum attainable for the

installation (inadequate sighting.

IMPORTANT:

Do not run the flame detector wiring in the same con-

duit with high voltage ignition transformer wires.

Connecting Detectors In Parallel

(C7927 Can Not be Used in Parallel)

For a flame that is difficult to sight, using two flame detectors

connected in parallel will reduce the occurrence of nuisance

shutdowns. If only one of the parallel detectors loses the flame

signal, the other will continue to indicate the presence

of the flame and keep the burner in operation.

When the flame detectors are connected in parallel, the low

level background signals are additive. Therefore, no more than

two C7027A, C7035A, or C7044A Flame Detectors should be

paralleled. Furthermore, the background signal increases as

temperature decreases. Because of this, the minimum ambient

operating temperature must be increased when the C7027A,

C7035A or C7044A Flame Detectors are paralleled. (C7927

can not be used in parallel.)

When using detectors rated for a minimum of 0°F (-18°C), limit

the minimum ambient temperature at the detectors to 32°F

(0°C). When using detectors rated for a minimum of

-40°F (-40°C), limit the minimum ambient temperature at the

detectors to -10°F (-23°C).

Connect the blue lead wires of both detectors to the F terminal

of the wiring subbase or terminal strip, and the white lead wires

of both detectors to the G terminal, as shown in Fig. 9.

Earth Ground

The detector and the flame safeguard control must be

connected to earth ground. A convenient method of

accomplishing this is to connect the detector to the flame

safeguard control with a flexible conduit, or ensure a good

ground connection at the mounting bracket.

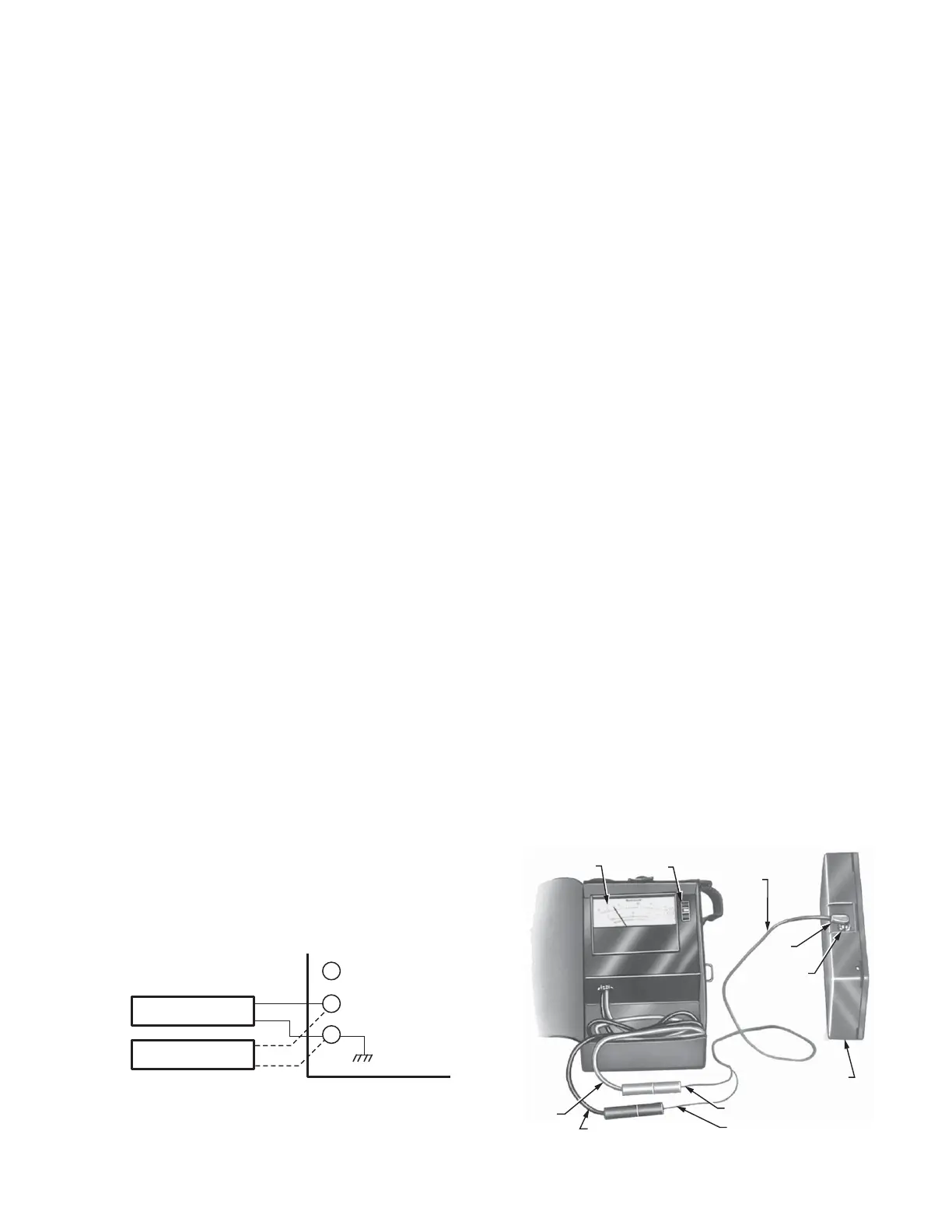

Fig. 9. Wiring C7027A, C7035A, and

C7044A flame detectors in parallel.

ADJUSTMENTS AND

CHECKOUT

Before welding the C7027A, C7927A or C7035A sight pipe

in its final location, or before tightening the C7044A clamp

screw, complete both the adjustments and checkout tests that

follow and any required by the burner manufacturer.

UV Sensor Tube Test

NOTE: For initial burner light off, consult the burner manufac-

turer instructions or the instructions

for the flame safeguard control.

During the initial burner light off, make sure the flame

safeguard control starts (i.e., the load relay, usually 1K, pulls

in). If it does not start, visually check the sensing tube in the

C7027A, C7035A, or C7044A flame detector. If the tube

continues to glow when no flame is present, replace the

sensing tube (C7035A), or replace the detector (C7027A or

C7044A).

Adjust Detector Sighting Position

With the flame detector installed and burners running, adjust

the position of the flame detector for optimum flame signal. The

flame signal will be read in microamps or voltage (Vdc)

depending on the Honeywell flame safeguard combustion

control used.

Most existing Honeywell flame safeguard controls incorporate

a flame current jack on the flame amplifier or on the control

itself. The flame signal can be measured with a volt-ohmmeter

such as the Honeywell W136A. To measure the flame current

(signal), use a cable connector (part number 196146, included

with the W136A) in conjunction with the meter. With the

W136A (or equivalent) positioned at the zero to 25

microampere scale, make connections from the meter probes

to the two ends of the cable connector plug (red to red, black to

black). Make these connections before inserting the plug end

of the connector plug into the flame jack of the control

or control amplifier (see Fig. 10). Read the flame signal in

microamperes directly from the W136A meter. Refer to

Table 1 for the minimum acceptable flame currents.

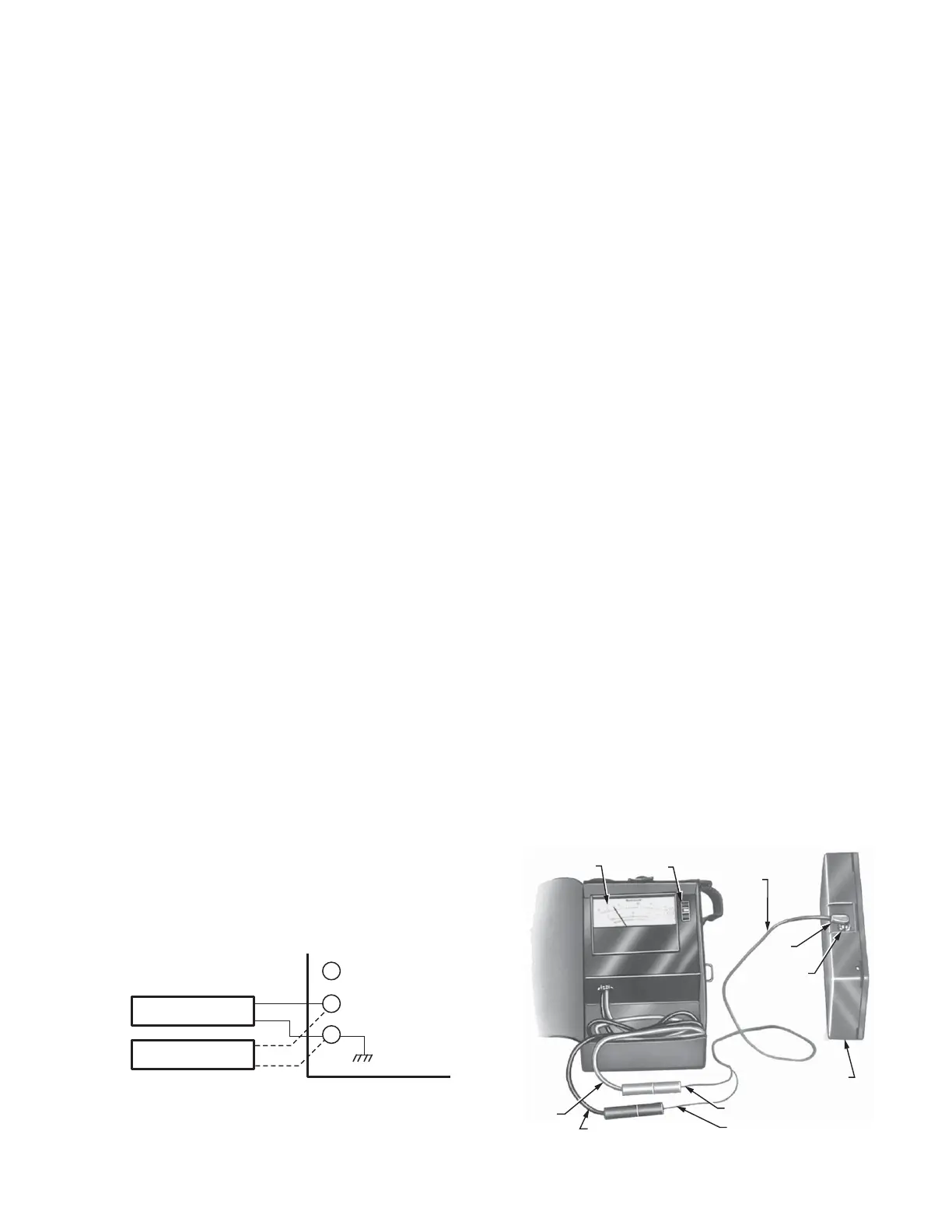

Fig. 10. Measuring microamp flame signal.

M3018A

F

WIRING SUBBASE

OR

TERMINAL STRIP

OPTIONAL

SECOND

DETECTOR

UV DETECTOR

UV DETECTOR

BLUE

BLUE

WHITE

WHITE

G

W136A VOLT-

OHMMETER

W136A SELECTOR

SWITCH

196146 METER

CONNECTOR

PLUG

PLUG

FLAME SIGNAL

METER JACK

PLUG-IN FLAME

SIGNAL AMPLIFIER

RED CONNECTOR

BLACK CONNECTOR

BLACK (-) METER LEAD

RED (+)

METER

LEAD

M6532B

Loading...

Loading...