35 AND 70 LB-IN. NON-SPRING RETURN DIRECT COUPLED ACTUATORS

9 63-2209—8

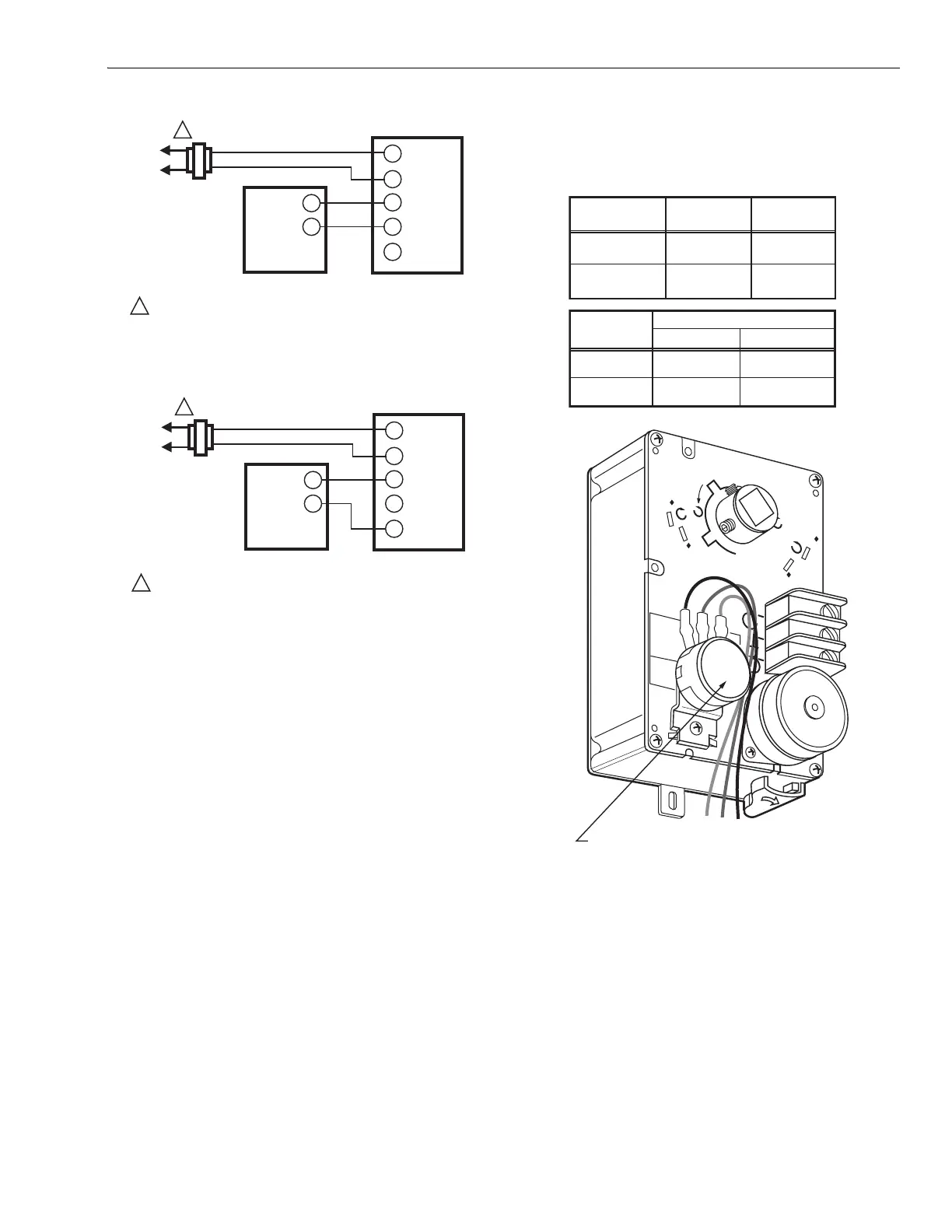

Fig. 13. ML7161 or ML7174 used with 2-10 Vdc control.

Fig. 14. ML7161 or ML7174 used with 4-20 mA control.

Auxiliary Switches

The 201052A or B Auxiliary Switch is used in conjunction with

the actuator. It allows for control of equipment external to the

actuator (for example, electric reheat coils and fan) at an

adjustable point in the stroke (0° to 90°) of the actuator.

The 201052A and B Auxiliary Switches are field-addable. For

mounting instructions, see form 63-2218, provided with the

device.

IMPORTANT

When operating an ML6161 or ML6174 from a two-

position controller, a 201052B Auxiliary Switch is

required for proper operation. See Fig. 12.

Auxiliary Potentiometers

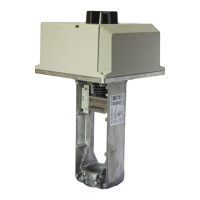

The 200976A,C Auxiliary Potentiometers mount on the face of

the ML6161A,C or ML6174A,C (as shown in Fig. 15). The

potentiometer shaft has a slipping collar. If one of the two

limits of the potentiometer is exceeded, the collar continues to

rotate, causing no damage to the potentiometer itself. To

mount the potentiometer on the actuator:

1. Turn the potentiometer to align the shaft key with the

slot in the potentiometer drive.

2. Tilt the potentiometer slightly so the key faces down

toward the slot.

3. Insert the potentiometer into the slot, and push down so

the potentiometer is flush with the actuator body and the

bracket is aligned over the screw hole.

4. Insert the screw provided into the hole and fasten

securely.

IMPORTANT

Failure to follow the calibration procedures can result

in improper resistance values at desired stroke.

Fig. 15. ML6161A,C, ML6174A,C with

field-addable potentiometer.

To Calibrate the 200976A,C:

IMPORTANT

Remove the range stop pins and minimum position

setscrews prior to calibration.

1. Drive the actuator fully closed (0°) to fully open (90°)

and back again to the fully closed position. This must be

done to receive the correct resistance readings at the

appropriate degree of stroke.

2. Check the resistance values of the potentiometer with

an ohmmeter at intervals in the stroke while referring to

the table in Fig. 15 and resistance information provided

in the Specifications section.

3. Replace the range stop pins and/or the minimum

position setscrews using the appropriate procedures.

L1

(HOT)

L2

1

1

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD

PROTECTION AS REQUIRED.

4-20 mA CONTROLLER

ML7161, ML7174

T1

T2

–

–

+

+ mA

+ V

M18071

L1

(HOT)

L2

1

1

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD

PROTECTION AS REQUIRED.

2-10 Vdc CONTROLLER

ML7161, ML7174

T1

T2

–

–

+

+ mA

+ V

M18072

60

45

45

60

CW

CCW

COM

M10251B

MOTOR

POSITION

RW

RESISTANCE

RB

RESISTANCE

FULLY CW

24V (COM-CW)

FULLY CCW

24V (COM-CCW)

0 OHMS

0 OHMS

500 OR

2000 OHMS

AUXILIARY POTENTIOMETER

MOTOR

ROTATION

AUXILIARY POTENTIOMETER LEADS

RW OHMS RB OHMS

CCW

INCREASE

DECREASE

DECREASE

INCREASE

CW

FIELD-ADDABLE AUXILIARY POTENTIOMETER

500 OR

2000 OHMS

B

R

W

Loading...

Loading...