SERIES 72 MODUTROL IV™ MOTORS

63-2202—410

SETTINGS AND ADJUSTMENTS

Zero and Span Adjustment for M7284Q and

M7285Q Motors (Fig. 5.)

1.

Adjust the start potentiometer fully clockwise (maximum

zero) and the span potentiometer fully counterclockwise

(minimum span).

2.

Set the controller current to the value required to drive

the motor to the closed position.

3.

Turn the start potentiometer slowly counterclockwise

until the motor begins to open. This is defined as the

start or zero setting.

4.

Set the controller current to the value required to drive

the motor to the fully open position. The motor will open.

5.

Turn the span potentiometer clockwise until the motor

starts to close. The difference between the fully open

span position current and the zero position current is

defined as the operating span.

6.

Recheck the start and readjust the span potentiometer

P1 if necessary. Turn the start potentiometer clockwise

to increase the zero position.

7.

Recheck the span and readjust the span potentiometer

if necessary. Turn it clockwise to increase the full span

position.

8.

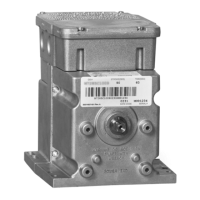

For sequential operation, as shown in Fig. 9, repeat the

above steps for each motor.

Fig. 9. Sequential operation of motors.

Auxiliary Switches

CAUTION

Electrical Shock or Equipment Damage Hazard.

Can shock individuals or short equipment

circuitry.

Disconnect all power supplies before installation.

Motors with auxiliary switches can have more than

one disconnect.

CAUTION

Equipment Damage Hazard.

Can damage the motor beyond repair.

Never turn the motor shaft by hand or with a wrench.

Forcibly turning the motor shaft damages the gear

train and stroke limit contacts.

Adjustable cams actuate the auxiliary switches. These cams

can be set to actuate the switches at any angle within the

motor stroke. Select switch differential of 1° or 10°.

Motors with factory added auxiliary switches are shipped in

the closed position (fully counterclockwise, as viewed from the

motor power end) with auxiliary cams set to actuate switches

30° from the closed position and to provide 1° degree

differential. With the motor in the closed (fully

counterclockwise) position, the auxiliary switch breaks

contacts R-B. See Fig. 10 for auxiliary switch wiring.

TRADELINE Motors are shipped with auxiliary switch cams

that permit acceptance of 220736A,B Internal Auxiliary Switch

Kits. Refer to form 63-2228 for 220736A,B Installation

Instructions.

20

(10)

16

(8)

12

(6)

8

(4)

4

(2)

0

CONTROL OUTPUT

mA CURRENT (OR VOLTS DC)

CLOSED

OPEN

CLOSED

OPEN

CLOSED OPEN

MOTOR 1 MOTOR 2 MOTOR 3

1 3 3 3

1

MOTOR 1 PROPORTIONS BETWEEN 4 AND 12 mA; FULLY

CLOSED AT 4 mA, FULLY OPENED AT 12 mA.

MOTOR 2 PROPORTIONS BETWEEN 8 AND 16 mA; FULLY

CLOSED AT 8 mA, FULLY OPENED AT 16 mA.

MOTOR 3 PROPORTIONS BETWEEN 12 AND 20 mA SIGNAL;

FULLY CLOSED AT 12 mA, FULLY OPENED AT 20 mA.

UP TO 6 MOTORS CAN BE DRIVEN SEQUENTIALY OR IN

UNISON FROM ONE CONTROLLER.

ADJUST ZERO ADJUST AND SPAN ADJUST POTENTIOMETERS

TO ACHIEVE DESIRED SEQUENCE.

2

2

3

SEQUENTIAL OPERATION

FOR ADJUSTABLE ZERO AND SPAN MODELS

M2893A

Loading...

Loading...