Do you have a question about the Honeywell Modutrol IV M7285 and is the answer not in the manual?

Details compatibility with electronic controllers providing proportional current output.

Defines motor rotation limits and states like mechanically/electrically normally closed/open.

Describes fixed 90°/160° strokes and field adjustable strokes.

Specifies nominal timing for 90° (30 sec) and 160° (60 sec) strokes.

Provides dead weight load limits for the motor shaft.

Specifies the acceptable operating ambient temperature range for the motors.

Details the dimensions of the motor shaft.

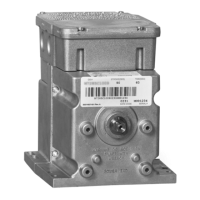

Refers to Figure 1 for detailed physical dimensions of the motors.

Provides guidance on selecting an appropriate installation location for the motor.

Details the correct procedure for mounting the motor in a horizontal position.

Explains the purpose and mounting procedure for the adapter bracket.

Describes how to use the adapter bracket with various valve and damper linkages.

Covers electrical connections, wiring box, and terminals for motor setup.

Explains the function and connection of auxiliary switches.

Procedure for setting zero and span on specific motor models.

Step-by-step guide for adjusting auxiliary switch cams and settings.

Explains how the motor feedback and control circuits function.

Key checks to perform after installation and linkage adjustment.

Specific steps to confirm the motor operates correctly as per input.

Loading...

Loading...