S8600B,C,H,M; S8610B,C,H,M; S8670D,E,J,K INTERMITTENT PILOT GAS IGNITION CONTROL

บริษัท เอดีดี เฟอร์เนส จํากัด

ADD FURNACE CO.,LTD.

44 ซอยบรมราชชนนี 70 ถนนบรมราชชนนี แขวงศาลาธรรมสพน์ เขตทวีวัฒนา กรุงเทพฯ 10170

โทร: 02-888-3472 โทร: ออกแบบ:08-08-170-170 แฟกซ์: 02-888-3258

https://www.add-furnace.com E-mail: sales@add-furnace.com

•

If necessary, adjust pilot flame by turning the

pilot adjustment screw on the gas control

clockwise to decrease or counterclockwise to

increase pilot flame. Following adjustment,

always replace pilot adjustment cover screw

and tighten firmly to assure proper gas control

operation.

•

Set thermostat below room temperature to end

call for heat.

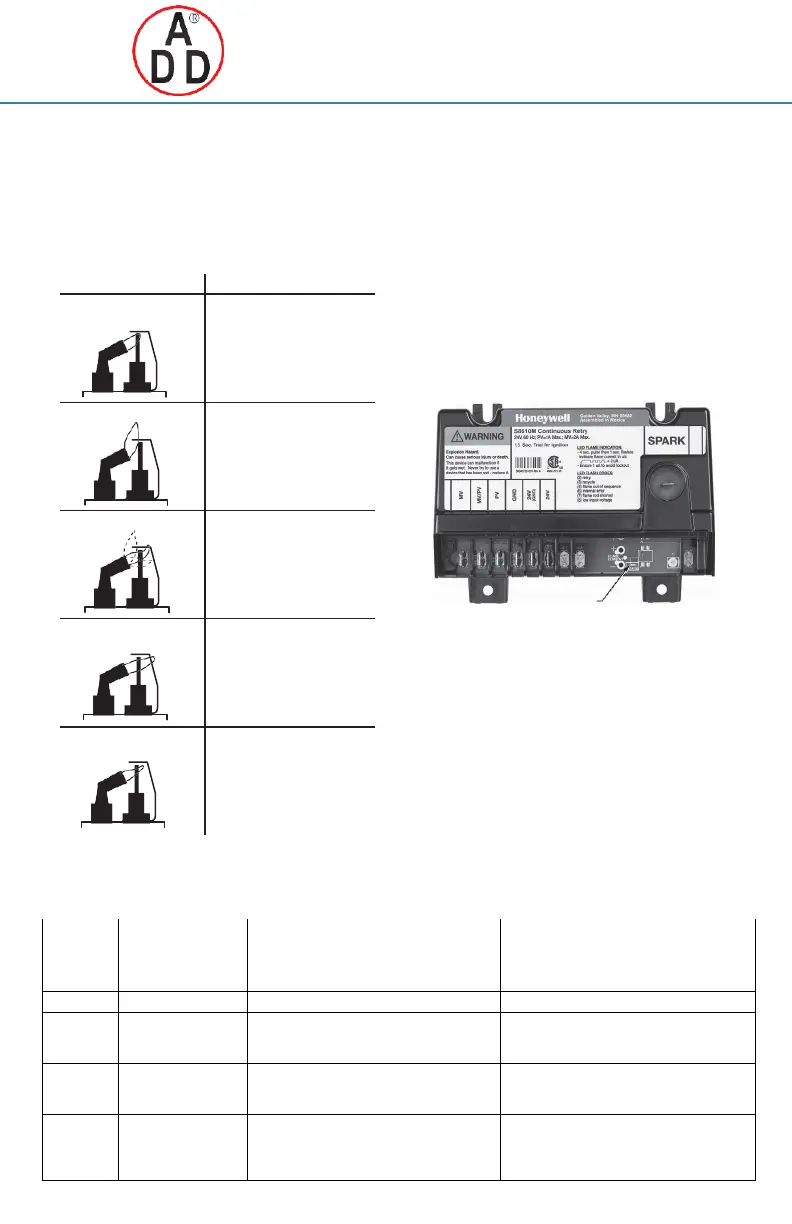

THIS FLAME IS CHARACTERISTIC

OF MANUFACTURED GAS

CHECK FOR:

•

HIGH GAS PRESSURE

•

ORIFICE TOO SMALL

M2233B

Fig. 11. Examples of unsatisfactory pilot flames.

•

Recheck ignition sequence as follows.

•

Reconnect main valve wire.

•

Set thermostat to call for heat.

•

Watch ignition sequence at burner.

•

If spark still doesn’t stop after pilot lights,

replace ignition control.

•

If main burner doesn’t light or if main burner

lights but system locks out, check the control,

ground wire and gas control as described in

“Troubleshooting” on page 10 and refer to the

Troubleshooting Guide (Fig. 14).

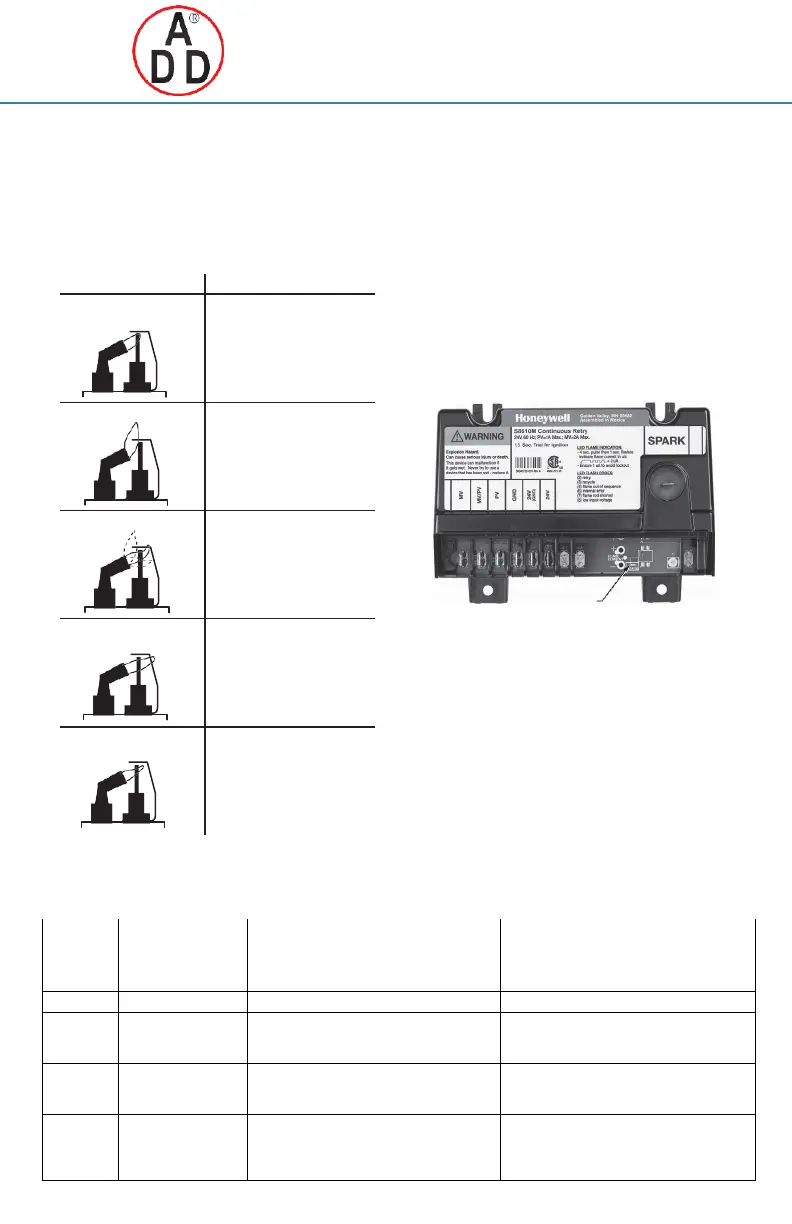

LED Status and Troubleshooting

The control has one LED used for flame sensing and

system status:

STATUS LED

M29907

Fig. 12. Location of LED.

Table 6. Continuous Retry Models C, M, E, and K Only—Green LED Status Codes.

Recommended Service Action

Power up - internal check

Normal startup - ignition

sequence started

(including prepurge)

4 Seconds

ON then “x”

flashes

Device in run mode. “x” =

flame current to the

nearest

A.

5 minute Retry Delay

- Pilot flame not detected

during trial for ignition

Initiate new trial for ignition after retry delay

completed.

If system fails to light on next trial for ignition check

gas supply, pilot burner, spark and flame sense

wiring, flame rod contaminated or out of position,

burner ground connection.

CHECK FOR LACK OF GAS FROM:

•

CLOGGED ORIFICE FILTER

•

CLOGGED PILOT FILTER

•

LOW GAS SUPPLY PRESSURE

•

PILOT ADJUSTMENT AT MINIMUM

CHECK FOR LACK OF AIR FROM:

•

DIRTY ORIFICE

•

DIRTY LINT SCREEN, IF USED

•

DIRTY PRIMARY AIR OPENING,

IF THERE IS ONE

•

PILOT ADJUSTMENT AT MINIMUM

CHECK FOR:

•

EXCESSIVE DRAFT AT PILOT

LOCATION

•

RECIRCULATING PRODUCTS

OF COMBUSTION

NOISY LIFTING BLOWING

FLAME

CHECK FOR:

•

HIGH GAS PRESSURE

Loading...

Loading...